Mxxx / Axxx

en-2 5022-D039778 Revision: 06

deutsch english italiano français español 日本語

Contents

1 About this manual ................................................................................................4

1.1 Signal words ........................................................................................................4

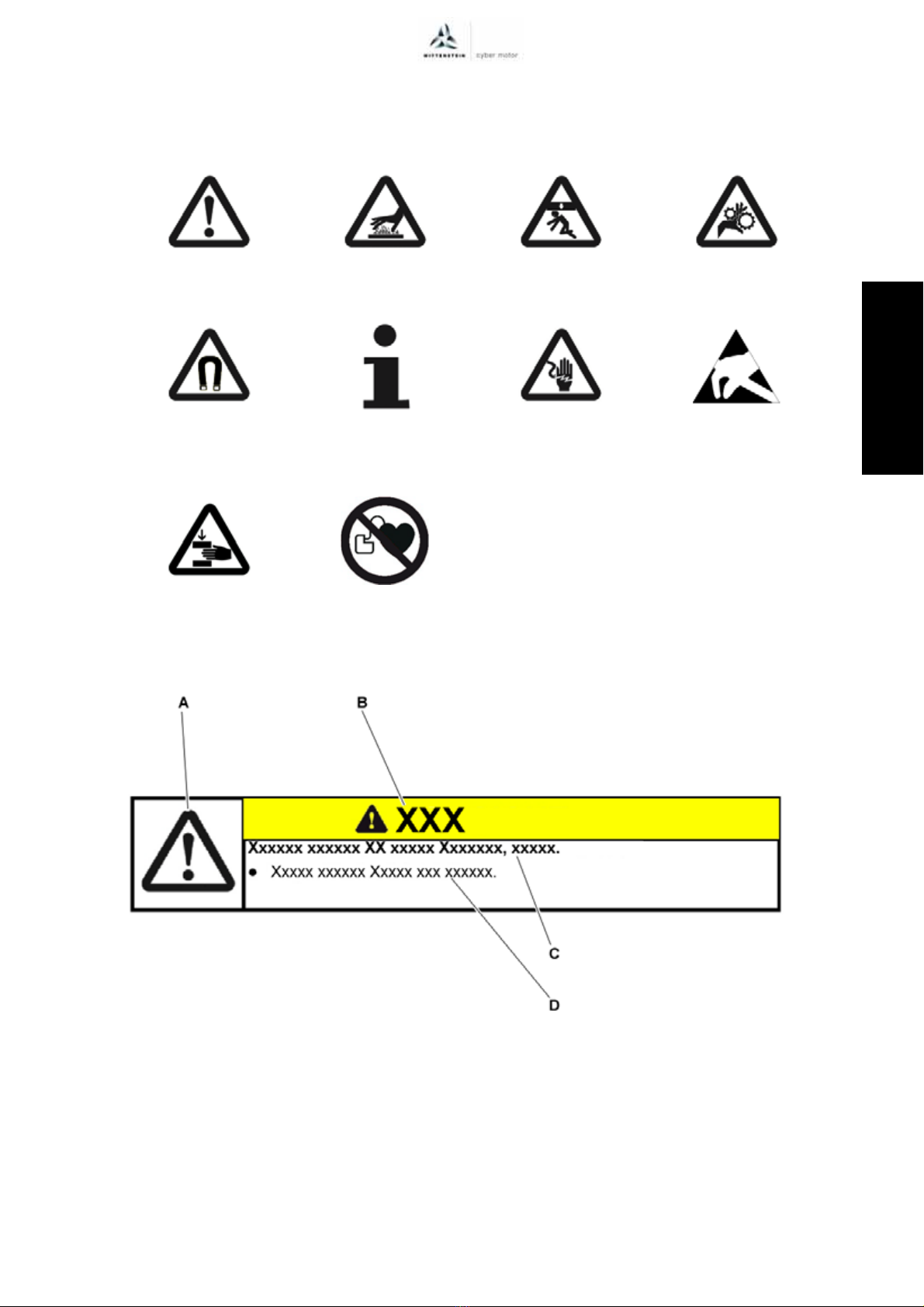

1.2 Safety symbols.....................................................................................................5

1.3 Design of the safety instructions ..........................................................................5

1.4 Information symbols.............................................................................................5

2 Safety.....................................................................................................................6

2.1 EC/EU Directive ...................................................................................................6

2.2 Dangers ...............................................................................................................6

2.3 Personnel.............................................................................................................6

2.4 Intended use ........................................................................................................6

2.4.1 Cooling type H and version H..........................................................................6

2.4.2 Version R.........................................................................................................6

2.4.3 Version V.........................................................................................................7

2.4.4 Version L .........................................................................................................7

2.5 Guarantee and liability .........................................................................................7

2.6 Other applicable documents ...............................................................................7

2.7 General safety instructions ..................................................................................7

3 Description of the motor....................................................................................11

3.1 General information ...........................................................................................11

3.2 Name plate.........................................................................................................11

3.2.1 MRxx series name plate................................................................................12

3.2.2 Name plate for ARxx series (motor-gearbox combination) ...........................13

3.2.3 ALxx series name plate (linear actuator).......................................................14

3.2.4 MLxx / PLxx / SLxx series nameplate (linear motor) .....................................15

3.3 Performance data ..............................................................................................15

3.4 Temperature monitoring.....................................................................................15

3.5 Weight................................................................................................................15

4 Transport and storage .......................................................................................16

4.1 Scope of delivery ...............................................................................................16

4.2 Packaging ..........................................................................................................16

4.3 Transport............................................................................................................16

4.4 Storage ..............................................................................................................16

5 Assembly ............................................................................................................17

5.1 Preparations.......................................................................................................17

5.1.1 Preparations for ALxx series (linear actuators) .............................................17

5.2 Attaching Motor to a machine ............................................................................18

5.3 Components mounted to the output side ...........................................................18

5.4 Connecting the cooling circuit ............................................................................19

5.5 Installing electrical connections .........................................................................20

5.6 Installing a kit motor ...........................................................................................21

5.6.1 Installing the stator ........................................................................................22

5.6.2 Installing the rotor..........................................................................................23

5.7 Installing the primary part / secondary part........................................................24

6 Startup and operation ........................................................................................26

6.1 Safety instructions and operating conditions .....................................................26

6.1.1 Humidity / Temperature.................................................................................26

6.1.2 Vibration ........................................................................................................26

6.1.3 Shock ............................................................................................................26

6.1.4 Holding brake ................................................................................................27

6.2 Operation ...........................................................................................................29

6.2.1 Voltage gradient ............................................................................................29

6.2.2 Operation of Mxxx / ARxx..............................................................................29