5

LPW / LPWS / LPWX ENGINE OPERATORS' HANDBOOK

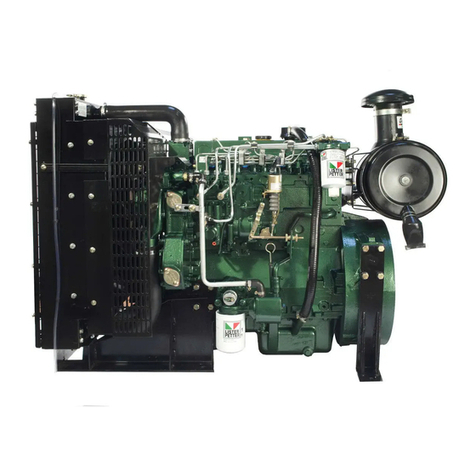

INTRODUCTION

This handbook explains the operation

and routine maintenance of Lister Petter

water cooled diesel engines in the Alpha

(LPW, LPWX) and New Alpha (LPWS)

series.

Please note that If your engine is part

of a generating set, there is a separate

operators' handbook for the genset,

to explain such features as the control

module.

ENGINE IDENTIFICATION

To identify which model of Lister Petter

LPWX/LPW(S) diesel engine you are

using refer to the engine serial number,

which is stamped on a plate attached to

the engine. It identifi es the type and build

of the engine (see table below) to enable

the correct maintenance procedures to

be carried out. Here is a sample serial

number:

06 001234 LPWS3 A 402

06........................Year code (06 = 2006)

001234...............Unique engine number

LPWS3 ............................ Engine model

A .........................Anti clockwise rotation

402....................................Build number

The illustrations on page 4 show features

of the different engine models. When

following the instructions in this handbook

you will need to be familiar with the parts

labelled.

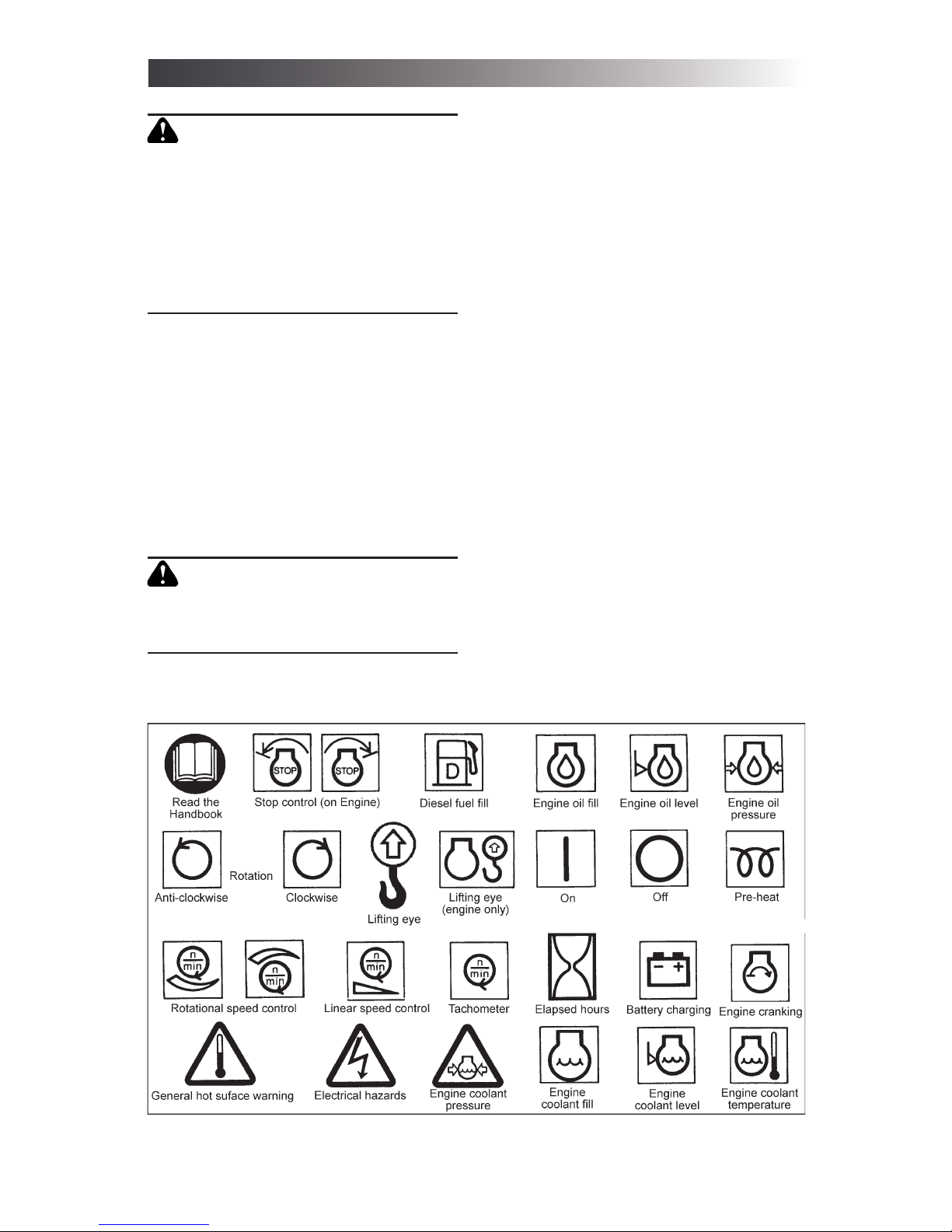

USING THIS HANDBOOK

Operating or servicing a diesel engine

is potentially dangerous. You must not

attempt it unless you have the necessary

knowledge and experience.

Read each section thoroughly and

carefully, taking note of all the information

and instructions given. This is for

your safety and to ensure the correct

maintenance of your engine. For specifi c

aspects of operation and maintenance,

use the table of contents (page 3) or the

index (page 40) to fi nd the section you

need. Where instructions are numbered

in sequence, they must be followed in

LPW DIESEL ENGINE MODELS

Model Characteristic features

LPW2 Two cylinders, water cooled, naturally aspirated, direct injection

LPW3 Three cylinders, water cooled, naturally aspirated, direct injection

LPW4 Four cylinders, water cooled, naturally aspirated, direct injection

LPWT4 Four cylinders, water cooled, direct injection, turbocharged

LPWX2 Two cylinders, water cooled, naturally aspirated, direct injection

LPWX3 Three cylinders, water cooled, naturally aspirated, direct injection

LPWX4 Four cylinders, water cooled, naturally aspirated, direct injection

LPWS2 Two cylinders, water cooled, naturally aspirated, indirect injection, emission compliant

LPWS3 Three cylinders, water cooled, naturally aspirated, indirect injection, emission compliant

LPWS4 Four cylinders, water cooled, naturally aspirated, indirect injection, emission compliant

LPWST4 Fourcylinders,watercooled,naturallyaspirated,indirectinjection,turbocharged,emissioncompliant