2

It is important that the installation of

the oil burner, piping and fittings, safety devices,

controls, electrical wiring and equipment be

done in accordance with national and/or local

regulations of the authorities having jurisdiction

over such installation.

Assembling the Burner (TWO-PAK)

1. Install air tuber assembly in housing using set

screws provided.

2. Install and tighten the proper nozzles. Be careful

not to damage the electrode insulators or to bend

the wires.

3. Check the electrode setting specified as follows:

1⁄8inch, 5⁄16 inch above the nozzle centerline and

¼ inch ahead of the nozzle tips. See Fig 1.

4. Swing open the ignitor assembly and slide the noz-

zle line assembly into the air tube.

5. Place the nozzle line yoke in the groove in the ad-

justing screw.

6. Fasten the high tension leads to the ignitor termi-

nals.

7. Swing the ignitor assembly to the closed position

and fasten.

8. Connect the flared fitting on the copper oil line to

the nozzle line and tighten.

About Combustion Chambers

The model 601CRD operates with superior efficiency

and cleanliness in properly designed refractory-type

combustion chambers. Very wide tolerance to burner

adjustments and other variables is found when these

chambers are used. Noise levels are also reduced.

Table 1, page 3 shows the recommended minimum

inside dimensions for refractory brick, refractory pre-

cast and pre-formed refractory fiber chambers. Due to

their quick warm-up properties, the lightweight insulat-

ing-type materials are slightly preferable although these

burners show less dependence upon refractory tem-

perature than previous models. Refractory materials in

boilers and furnaces should be capable of withstanding

2600°F (1427°C) or higher.

The notes accompanying Table 1 provides further de-

tails relative to variations in dimensions and geometry.

Refer to Fig. 3, page 3.

Firing Boilers without Refractory

Chambers

Depending upon the geometry of the combustion

space some units perform better than others without

refractory. When the back wall of the unit coincides

approximately with the end of the flame, a target of

refractory material is essential. Zero smoke readings

are made easier if a refractory fiber “rug” or fill material

is used on the base under the flame.

Table 1, page 3, together with its footnotes, gives

the essential dimensions and information needed to

provide conditions for satisfactory operation without

complete chambers. Refer to Figs. 4 and 5, page 3.

Installing the Burner:

Flange Mounted

1. Measure, in the burner opening, the distance from

the inside of the combustion chamber to the outside

of the mounting plate to find the insertion length of

air tube needed. Position flange on air tube at point

from end of burner corresponding to the measure-

ment. Tighten set screws to anchor flange. The

flange is now located so that the end of the burner

will be flush, or almost flush, with the inside of the

combustion chamber. See Fig. 3 (side view) page 3,

and Fig. 6, page 3.

2. Slide the end of the air tube into the opening and

secure the flange to the front plate.

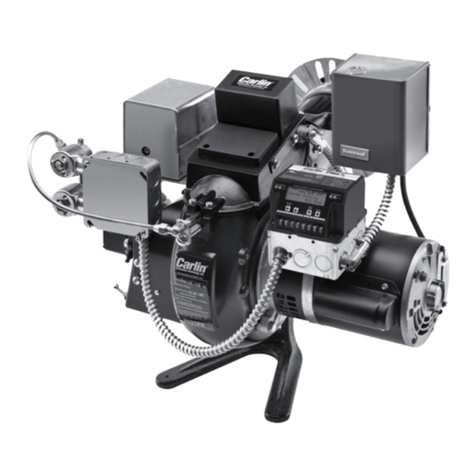

Installing The Burner:

Pedestal Mounted

1. Adjust the pedestal so that the height of the air tube

matches the’ location of the burner opening.

2. Slide the end of the air tube into the opening so that

it is flush or nearly flush with the inside of the com-

bustion chamber. See Fig. 7.

3. From the outside of the unit, seal the space around

the air tube with refractory cement or equivalent.

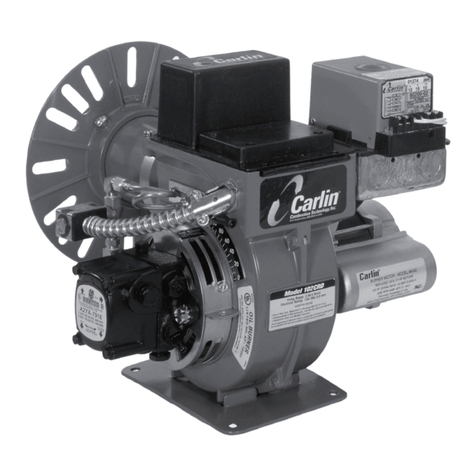

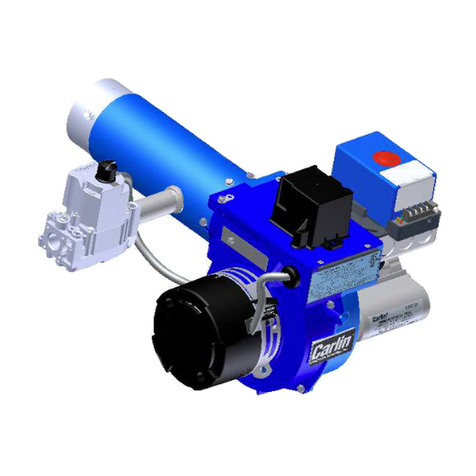

Fig. 1

Electrode

Settings