6

2. Burner Operation

OPERATION: LOW-HIGH-OFF

(No optional Aquastat or Pressuretrol, supplied by others)

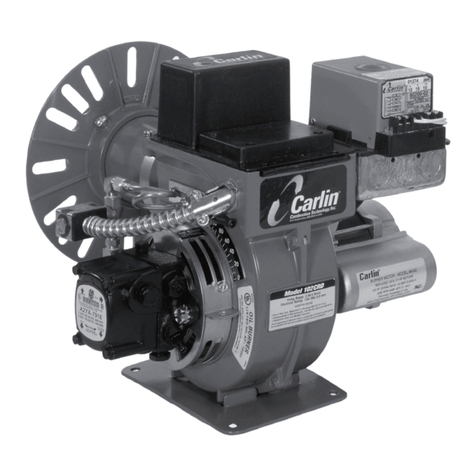

The 702CRD is supplied with a 70200 oil

primary control pre-programmed from

the factory with a 30 second valve delay

ON (pre-purge) and a 30 second Motor

Delay Off (Post Purge). A constant 120

volts should be supplied to the “line in”

on the 70200 primary.

Do NOT use any control that has less

than a 10 second valve delay ON (pre

purge). 10 second pre purge ensures the

damper returns to the low fire air position

before start up in a case where the con-

trol has no motor delay off (post purge)

and/ or there is not 120 volts suppled to

the “line in” on the control

It is important that the installation of

the oil burner, piping and fittings, safety

devices, controls, electrical wiring and

equipment be done in accordance with

national and/or local regulations of the

authorities having jurisdiction over such

installation.

1. Upon a call for heat, the 70200 primary control will

indicate pre-ignition and turn on the ignitor for 3 sec-

onds before energizing the motor.

2. The 70200 will then energize the orange lead and pull

in the motor contactor, indicating valve delay ON (pre-

purge) for 30 seconds. At the end of the 30 second

pre-purge, the low fire oil and redundant safety valves

(located on the left side of the junction box) will open

and supply oil to the nozzle with pressure between

100 PSI and 150 PSI

3. After ignition and a 15 second delay, the burner will

drive to high fire (as long as the low fire hold switch is

in the up position).

As the damper motor drives to high fire and begins

to open the air shutter the damper motor end switch

will energize the high fire blocking valve located on

the pump, and will increase the pump pressure at the

nozzle up to 300 PSI. The air shutter will continue to

open until it it fully open (see Siemens Damper motor

instructions, page 9, for low/high end switch transi-

tion adjustments, if needed).

When the call for heat is satisfied, the burner will shut

off.

OPERATION: LOW-HIGH-LOW-OFF

Using low-high-low-off operation typically

saves 20% on fuel usage.

Using either an additional aquastat for a water boiler

or a pressure control for a steam boiler, wire your control

to break the (low-high operation) of the damper motor

by identifying a tagged wire nut in the oil valve junction

box. The burner will now operate Low-High-Low-Off.

(See wiring diagram for details.)

1. On a cold start call for heat, the burner will drive to

high fire.

2. As the temperature or steam pressure begins to reach

the operating limit the L-H-L controller (set below

operating high limit) will drive the burner to Low Fire.

3. If the temperature or pressure drops below the dif-

ferential of the L-H-L controller it will drive the burner

back into high fire.

4. If low fire can reach the operating limit demand, the

burner will shut off and remain in stand by until the

next call for heat.

NOZZLE SPECIFICATIONS

• Always use the Carlin OEM Burner Setup Tables for

nozzle specifications when the appliance is listed,

Many nozzles are available through your wholesaler or

Carlin Combustion.

• If your appliance is not listed in the OEM Burner Setup

Tables, you may use Table 1 on page 2. The 60B

Hago nozzle is the standard nozzle for this burner and

usually provides the best combustion results. Other

makes of nozzles may or may not provide satisfactory

combustion results.

FORCED DRAFT FIRING

Due to the back pressure in forced draft units, the max-

imum firing rate of a burner is reduced. The greater the

pressure, the lower the maximum GPH capability

becomes. Table 1 (page 2) shows this. Note that the

Table stops at 0.70 inches W.C., the maximum recom-

mended back pressure for the 702CRD burner.

The combustion head settings for forced draft firing

would be somewhat greater than those shown in Table 1

(page 2) which is for zero pressure or natural draft.