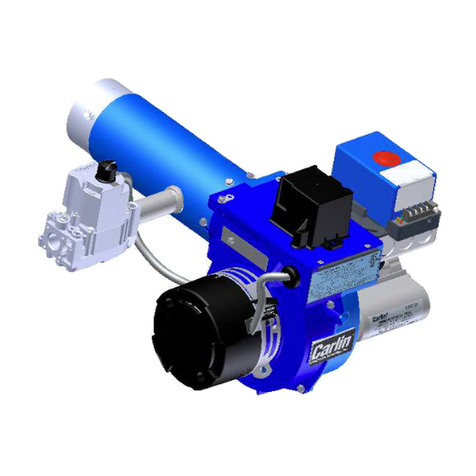

Model 99FRD, 100CRD, & 102CRD oil burners — Instruction manual

Carlin part number MN99102 Rev. 08/20/08 – 5 –

Combustion/ventilation air checklist

The burner may operate successfully under momentary

downdraft conditions, but sustained downdraft is unsafe.

This can occur with an inadequate or incorrectly installed

chimney/vent. It can also occur in rooms/buildings equipped

withexhaustfansorunsealedreturnairducts.Alwayscheck

operation of the burner under all conditions to verify vent system

operates correctly. You may have to interlock the burner with

exhaust fans to shut burner off when fan operates; or provide

make-up air to the appliance room sufficient to prevent any

negative pressure in the space. Failure to correct downdraft

or negative room pressure operation could result in severe

personal injury, death or substantial property damage.

❏ Verify that openings are unobstructed.

❏ Verify that appliance space and air source spaces are free of:

• Gasolineorotherammableliquidsorvapors.

• Combustiblematerials.

• Aircontaminantsandchemicals,suchaslaundryproducts,paint,thinner,

varnish, etc.

❏ Conrmwiththebuildingownerthattheareawillbekeptfreeofthese

materials at all times and that air openings will be kept unobstructed.

2. Prepare site • assemble burner • mount burner (continued)

Verify combustion chamber

Chamber dimensions and construction

• Ifretrottingtheburnertoanappliance,installtheburnerinaccordance

with the appliance instruction manual, when available. If no specific

application data is available from the appliance manufacturer, read the

guidelinesinFigure1,page6,tocheckwhethertheburnerislikelyto

work acceptably in the application.

Verify clearances

Verify that the burner/appliance will maintain all clearances from combus-

tible construction and clearances for service/maintenance as required in

the appliance manual and applicable codes.

Verify that the vent system components maintain all necessary clearances

to combustible construction, including the correct design of thimbles and

insulation where penetrating combustible walls.

• IllustrationsAtoFinFigure1showdifferentchambercongurations

with and without refractory linings. The chamber dimensions listed in

Figure 1 depend on whether the chamber is lined or water-backed.

• Donotattempttoretheburnerinachamberwithdimensionssmaller

thanshowninFigure1,page6,unlesstheapplicationhasbeenspeci-

callytestedandlistedbytheappliancemanufacturerand/orCarlin.

• Chambers with dimensions larger than shown in Figure 1, page 6,

should not have much effect on combustion/performance.

General guidelines

• Cleanallapplianceuesandheatingsurfacesthoroughly,removingall

soot and scale.

• Sealalljointsandgapsusingfurnacecementtopreventexcessair

infiltration.

The99FRDwrapped-shieldairtubemustbeusedonlyin

wet-base combustion chamber applications.

Using chamber linings and lightweight chambers

• Whenusingrefractorylinersorlightweightchambers,useinsulating-

typerefractoryrated2300°Fminimum.

• Youmustinstallatargetwalllinerifamelengthisclosetothelength

of the chamber.

• Useaoorlinerwhenpossible.Theoorlinerwillimproveringinmost

applications.Extendoorliner3to4inchesupsidewall.

• Targetwallliners—Corbelthetopoftargetwallliners1½to2½inches

deepandextendatleast3to4inchesabovethecenteroftheame.

• Usepre-formedchamberlinerswhenavailable.

• Forringratesbelow0.75GPH,itisbesttoapplyinarefractory-lined

orstainlesstube(designedforapplication)chamber.Liningtheoor

and target wall of the chamber with lightweight insulating refractory

will accomplish the same.

• Whenconversionringcoal-redunits,installacombustionchamberin

the ashpit area, or fill ashpit with sand up to 2 inches above the “mud

ring” of a boiler (firing through the door). Install a lightweight refractory

lineronthetargetwallasinFigure1F,page6.Makesuretheminimum

dimensions comply with those for Figure 1F.