– 3 –

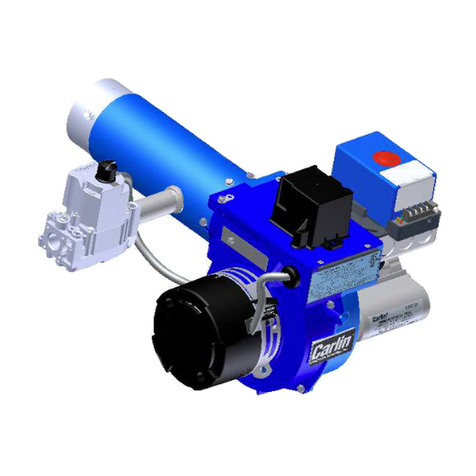

Burner applications

Followallinstructionsinthismanual,theprimarycontroldatasheetand

theappliancemanual.

Verifytheburneriscorrectfortheappliancebeingusedandforallap-

plicablecodes/standards.

Adjustthenozzleselection/ringrateifnecessaryduetopositiveoverre

pressureand/oraltitudesmorethan2,000feetabovesealevel.Seethe

NOTICEundertheRatingsinformationatright.Whereapplianceappli-

cationinformationisavailable,therecommendedringrateandburner

informationwill includeappropriate adjustmentsforpositive overre

pressureandrecommendationsforhighaltitudes.Followtheappliance

manualguidelineswhenavailable.

Damage or shortage claims

Theconsignee ofthe shipmentmust ledamage orshortage claims

immediatelyagainstthetransportationcompany. Seethe NOTICEon

page1forburnercartoninformation.

When calling or writing about the

burner:

PleaseprovideuswiththeULserialnumberandburnermodelnumber

toassistusinlocatinginformation.Thisinformationcanbehelpfulwhen

troubleshootingorobtainingreplacementparts.

Codes and standards

Certification

801GASburnersareU.L.listedfortheU.S.,certiedtocomplywith:

• UL295,forusewithnaturalgasorpropane.

• Burnerlabelslistcompliance,whenrequired,withspeciallocal,state

orprovincialapprovals.

Installthisburnerinaccordancewithalllocalcodesand

authoritieshavingjurisdiction.Regulationsoftheseauthori-

tiestakeprecedenceoverthegeneralinstructionsprovided

inthismanual.

United States installations

Burner/applianceinstallationsintheUnitedStatesmustcomplywiththe

latesteditionsof:

• InstallationofDomesticGasConversionBurners,ANSIZ21.8.

• NationalFuelGasCode,ANSIZ223.1/NFPA54.

• NationalElectricalCode,ANSI/NFPA70.

• Alladditionalapplicablenational,stateandlocalcodes.

The801GASburner,conguredforMassachusettsCode

compliance,differsfromthestandard801GASin:

1 Lowandhighgaspressureswitchesareaddedtothegas

train.

2 JumperJR2ontheprimarycontrolisclippedandremoved,

causingthecontroltobenon-recycling.

Ratings

(With0.00”w.c.overrepressure,altitude2,000feetmax.;

seeNOTICEbelow)

Gas Input

......................................... Highre(51600A):1,400to2,100MBH

......................................... Lowre(51600B):2,100to2,500MBH

Fuels

....................................................................Naturalgasorpropane

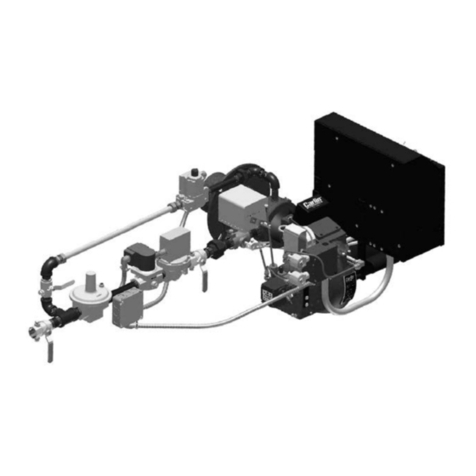

Gastrain:(availableinstraightorangledconguration)

...........................................(2)Maingasvalves&RV-81regulator

............................................ Butterygasvalveforinputregulation

................................. 11⁄2"gastrainstandard;2"gastrainavailable

Electrical

Power............................................................ 120

60

/1-

Limitcircuitinput........................................................ 120

/60

Controlcircuitload(120vac).............................................

Motor...................................................

3/4 hp, 3450 rpm, 56c-frame

..............................

115 / 208-230 vac/60 hz/1-ph, 9.8 / 4.8-4.9 amps

...................... Opt:208-230/460

/3-

,3.0-3.2/1.6

Dampermotor(withendswitch)...........................Siemens sQN71

Ignition & primary control

....................................................... Carlinsolidstate41800ignitor

Ignitionvoltage.............................................................. 9,000

Primarycontrol...............................................HoneywellRM7897C

..........................................................................Alt:

Agencies

................................................................................. ULListed(US)

Reducenozzle/ringrate when required — Maximumburner

capacityisreducedwhenoverrepressureispositiveandfor

altitudesabove2,000 feet.Seebelow,and adjustringrate/

nozzleselectionifnecessary.

801GAS – Maximum ring rate for

positive overre pressure and high altitutde

Altitudes:Foraltitudesmorethan2,000feetabovesealevel,reducethe

abovecapacitiesanadditional4%per1,000feethigherthan2,000

feetabovesealevel.

General information

2520

2380

2240

2100

1960

1820

1680

1540

1400

1260

1120

18

17

16

15

14

13

12

11

10

9

8

0 .1 .2 .3 .4 .5 .6

BACK PRESSURE IN FIREBOX – INS. W.C.

MAXIMUM FIRING RATE – GPH

MAXIMUM FIRING RATE – MBH