Thermal•Aire II Convection Tray Cart | 2

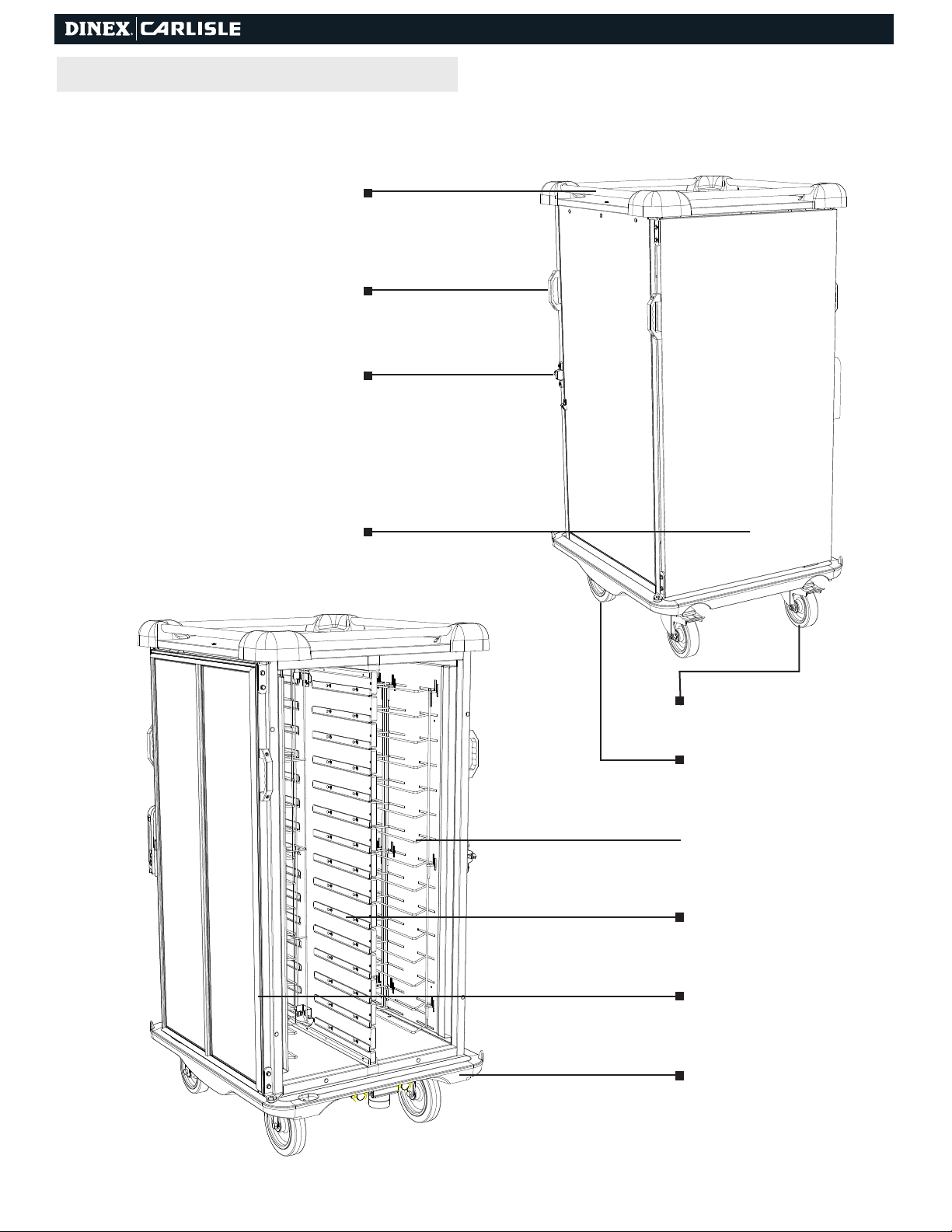

INTRODUCTION

INFORMATION ON THIS SECTION

When contacting customer service please provide the following

information located on the product identication plate:

• Identication Number of the equipment

• Designation of the equipment

IDENTIFICATION PLATE

Different identication number for each machine made.

SAFETY

!

CAUTION:

• Do not carry heavy, unstable or hazardous loads on the upper

surface.

• Do not climb on the bumper.

• Do not stop the cart on a slope without aligning and locking the

wheels.

• Wear protective gloves when handling or cleaning hot sections of

the cart (inside doors and middle section) to prevent burns.

• Wear gloves and glasses when cleaning the cart for protection

from cleaning products.

• Maximum speed authorized is 3 mph. Curves should be taken at

a lower speed: 1.5 mph.

• The telescopic tow-bar are designed only for indoor towing on

smooth surfaces. Do not tow more than three carts at a time.

Never unhitch carts on sloping surfaces.

RECOMMENDATIONS

!

IMPORTANT:

• Do not remove the Thermal•Aire II cart’s identication plates.

• Lock the wheels as soon as the cart is connected to the docking

station. Lock them also and point the wheels towards the bottom

of the slope when the machine is stopped on a slope.

• It is strictly forbidden to tilt the cart by pressing on a door to

empty washing water. This would damage the hinges and result

in poor door latching.

• During tray distribution to the patients, it is recommended to open

only one door at a time. By doing so, the Thermal•Aire II cart and

the trays will remain at the right temperature for a longer time.

• For best operating conditions in cook and serve, cold food should

be under 40°F and hot food over 165°F. In cook-chill, the various

dishes prepared in the kitchen should be cooled between 33°F to

40°F before being loaded in the cart.

• Maximum weight per tray: 5.3 lbs.

• Food must be covered or wrapped.

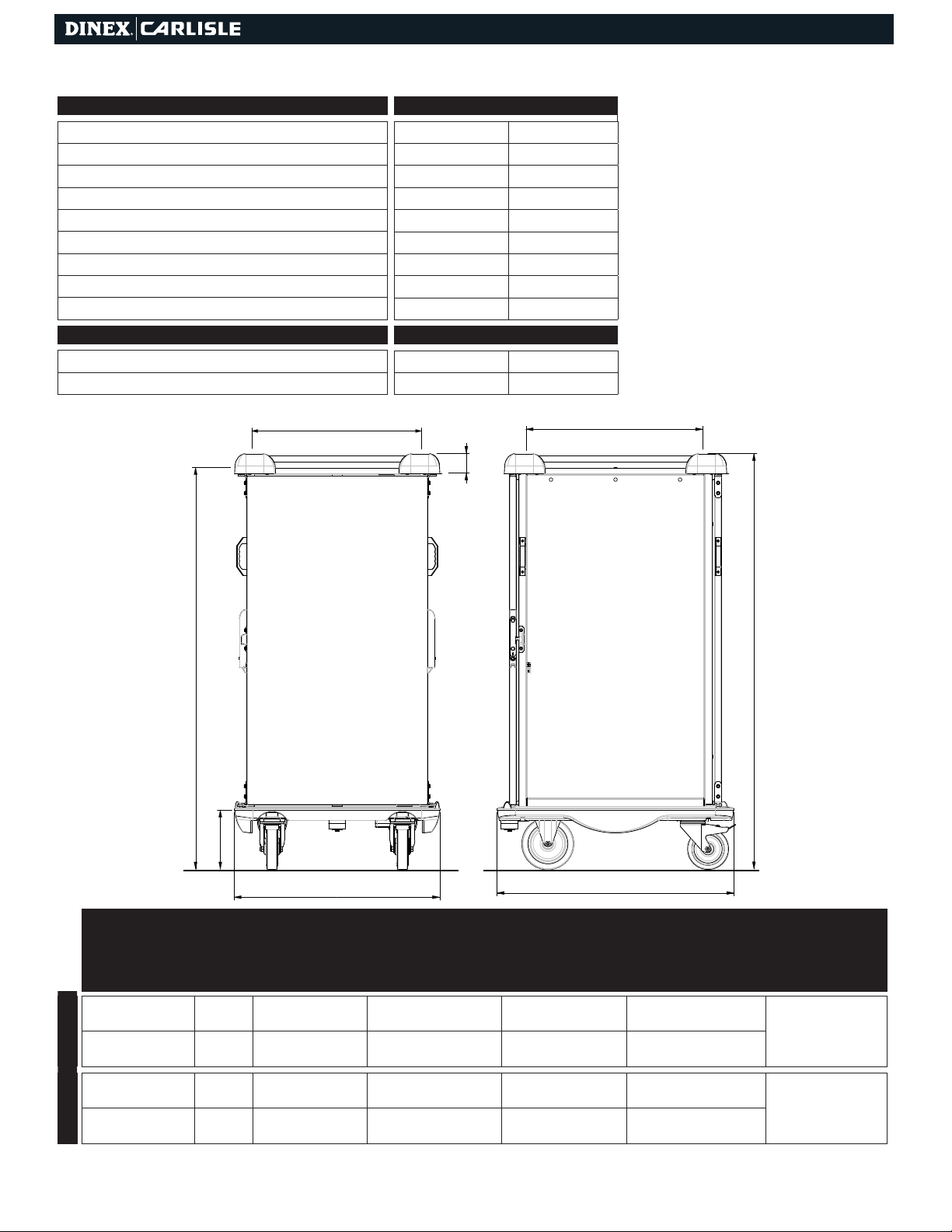

DESIGNATION

IDENTIFICATION

DATE

Made in France for DINEX by SOCAMEL TECHNOLOGIES

BY CARLISLE FSP

OKLAHOMA CITY, OK 73152

FOR SERVICE CALL

888-673-4639