NPN),VON 1.2VDC/max.100mA;VOFF 30VDCmax.accordingtoDIN43864;

pulse duration: 20ms (ON), 20ms (OFF); insulation: by means of

optocouplers, 4000VRMS between output and measuring inputs,

4000VRMS between output and power supply input.

RS485/RS422 SERIAL OUTPUT (IF AVAILABLE): multidrop: bidirec-

tional (static and dynamic variables); 2 or 4 wires; maximum distance

1200m; termination and/or line bias selectable directly by dip-switch; 255

programmable addresses; data format: 1 start bit, 8 data bits, no parity /

even parity, 1 stop bit; baud rate: 1200, 2400, 4800 and 9600 baud

selectable by key-pad; protocol according to the MDOBUS/JBUS.

Reading of single phase variables:

P, PAVG, S, Q, PF (cosϕ), VL-L, f, energy and status of digital inputs, set-

point output and status of the energy overflow bit, transducer's model.

Reading of single phase variables:

PL1, SL1, QL1, PF (cosϕ)L1, VL1-N, IL1

PL2, SL2, QL2, PF (cosϕ)L2, VL2-N, IL2

PL3, SL3, QL3, PF (cosϕ)L3, VL3-N, IL3

Writing: all programming parameters, reset of the energy overflow bit,

reset of energy totalization, activation of static output.

Stored energy (EEPROM): 250.000.000 kWh

Insulation: by means of optocouplers, 4000VRMS between output and

measuring inputs, 4000 VRMS between output and power supply input.

Temperature drift: 200 ppm/°C

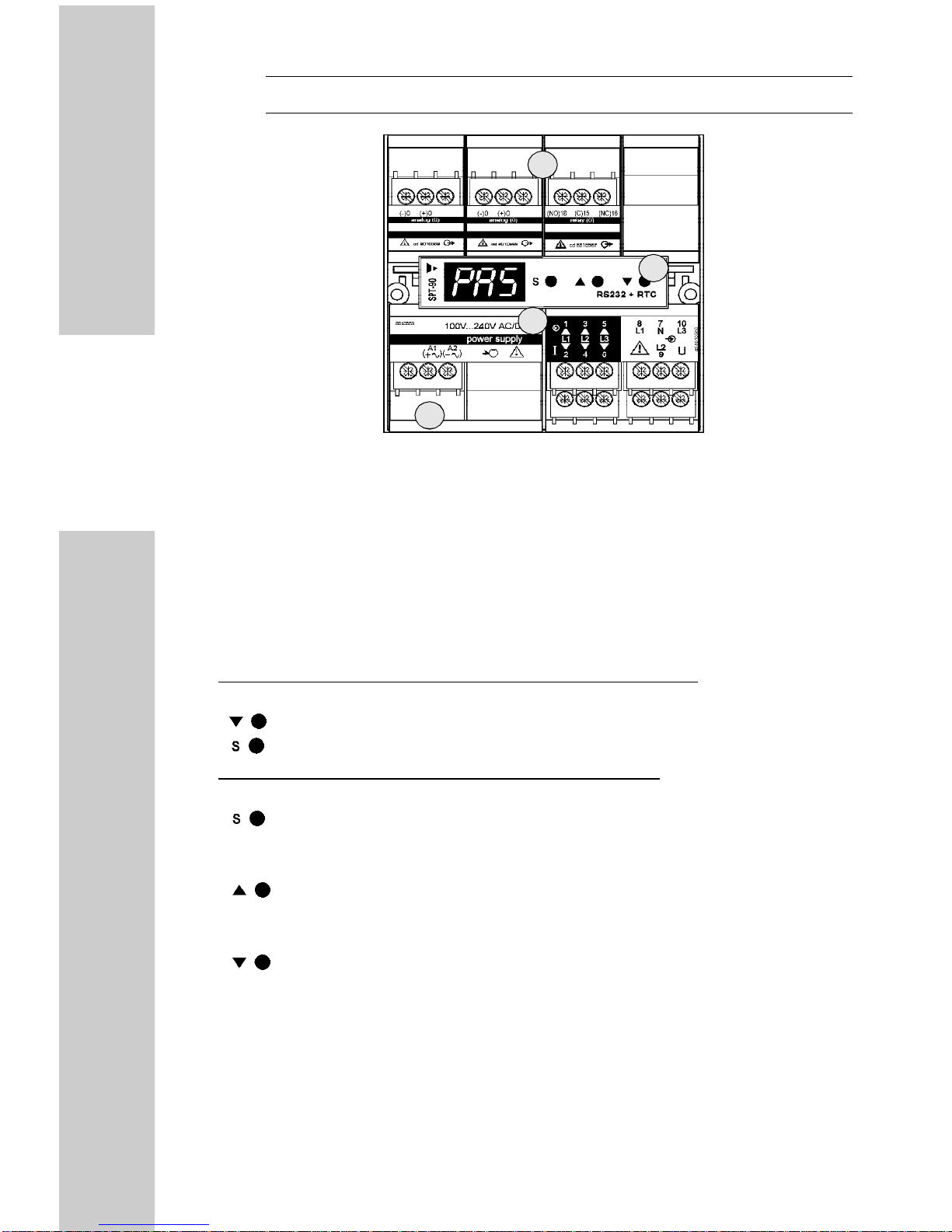

RS232 SERIAL OUTPUT (IF AVAILABLE): bidirectional (static and

dynamic variables); 3 wires; maximum distance 15m; data format: 1 start

bit,8databit,noparity,1stopbit;baudrate:9600baud;protocolaccording

to MODBUS/JBUS.

Other specifications: same as RS485/RS422

POWER SUPPLY INPUT

From 90 to 260VAC/VDC, 50/60 Hz;

From 18 to 60VAC/VDC, 50/60 Hz;

Self-consumption: ≤30VA / 20W (from 90 to 260V)

≤ 20VA / 20W (from 18 to 60V)

OPERATING TEMPERATURE

: from 0 to +50°C (R.H. < 90% non-condensing)

STORAGE TEMPERATURE

: from –10 to +60°C (R.H. < 90% non-condensing)

REFERENCE VOLTAGE FOR THE INSULATION: 300VRMS to earth

INSULATION: 4000VRMS between all outputs/inputs to ground

DIELECTRIC STRENGTH: 4000VRMS for 1 minute

NOISE REJECTION (CMRR): 100 dB, from 48 to 62 Hz

ACCORDING TO THE FOLLOWING STANDARDS:

Electromagnetic compatibility: EN 50 081-2, EN 50 082-2

Safety: IEC 61010-1, EN 61010-1

Product: IEC 60688-1, EN 60688-1

Pulse output: DIN 43864