Absorption Chiller Installation Manual

<Hot water fired type>

Table of Contents

1. INSTALLATION

1-1. USE ENVIRONMENT ................................................................................................................... 1

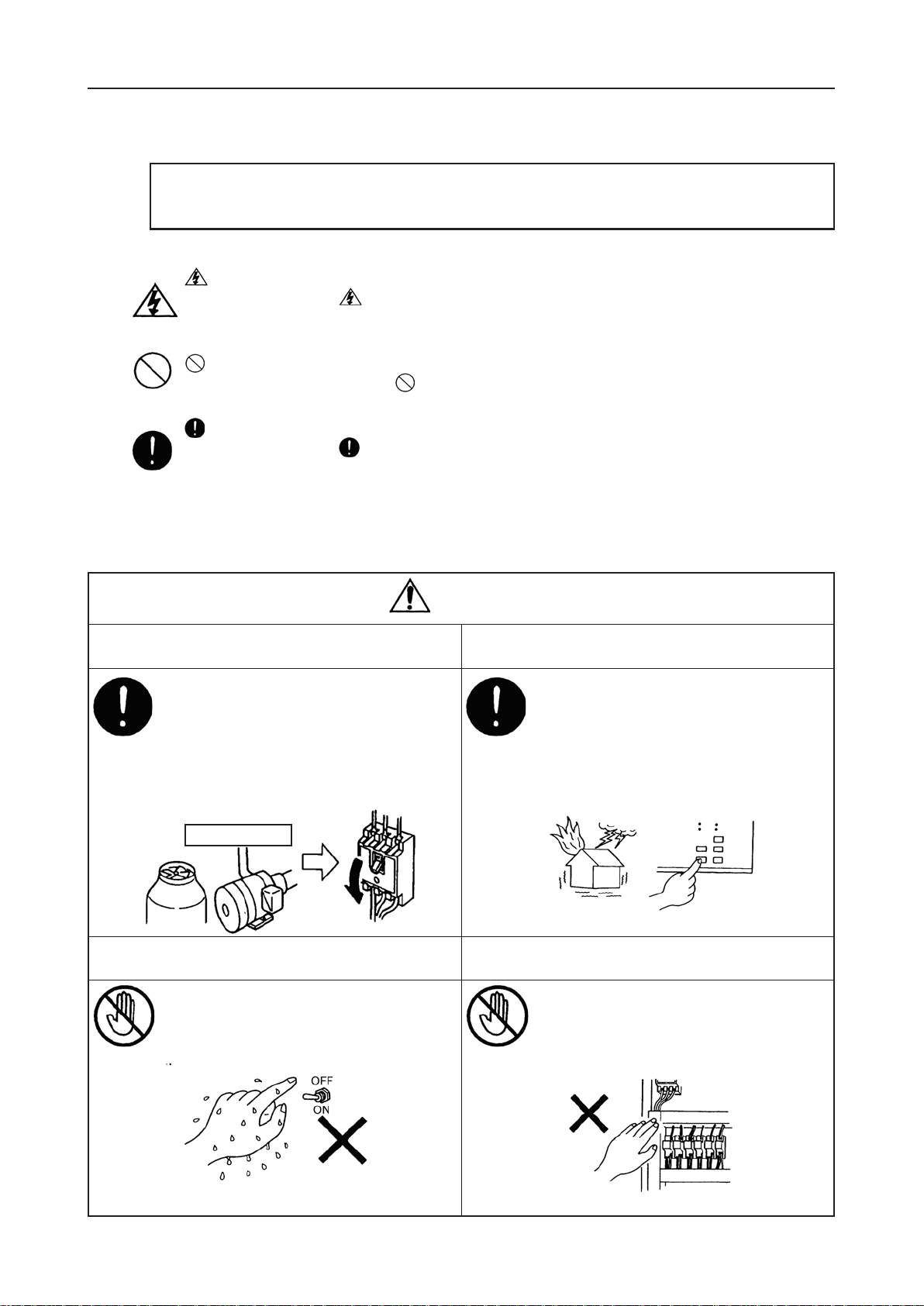

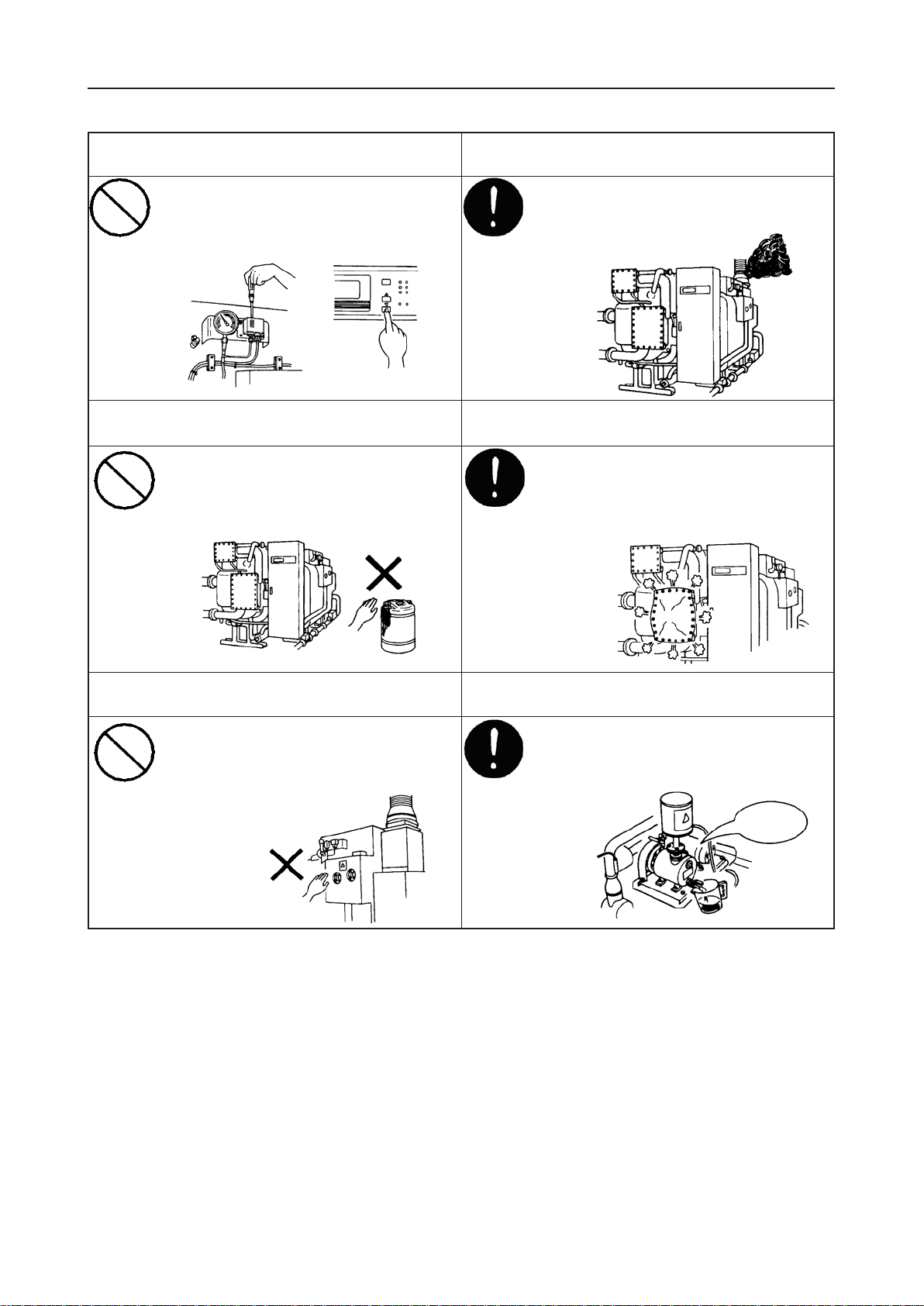

1-2. SAFETY INSTALLATION .............................................................................................................. 7

1-3. DELIVERY INSPECTION ............................................................................................................. 7

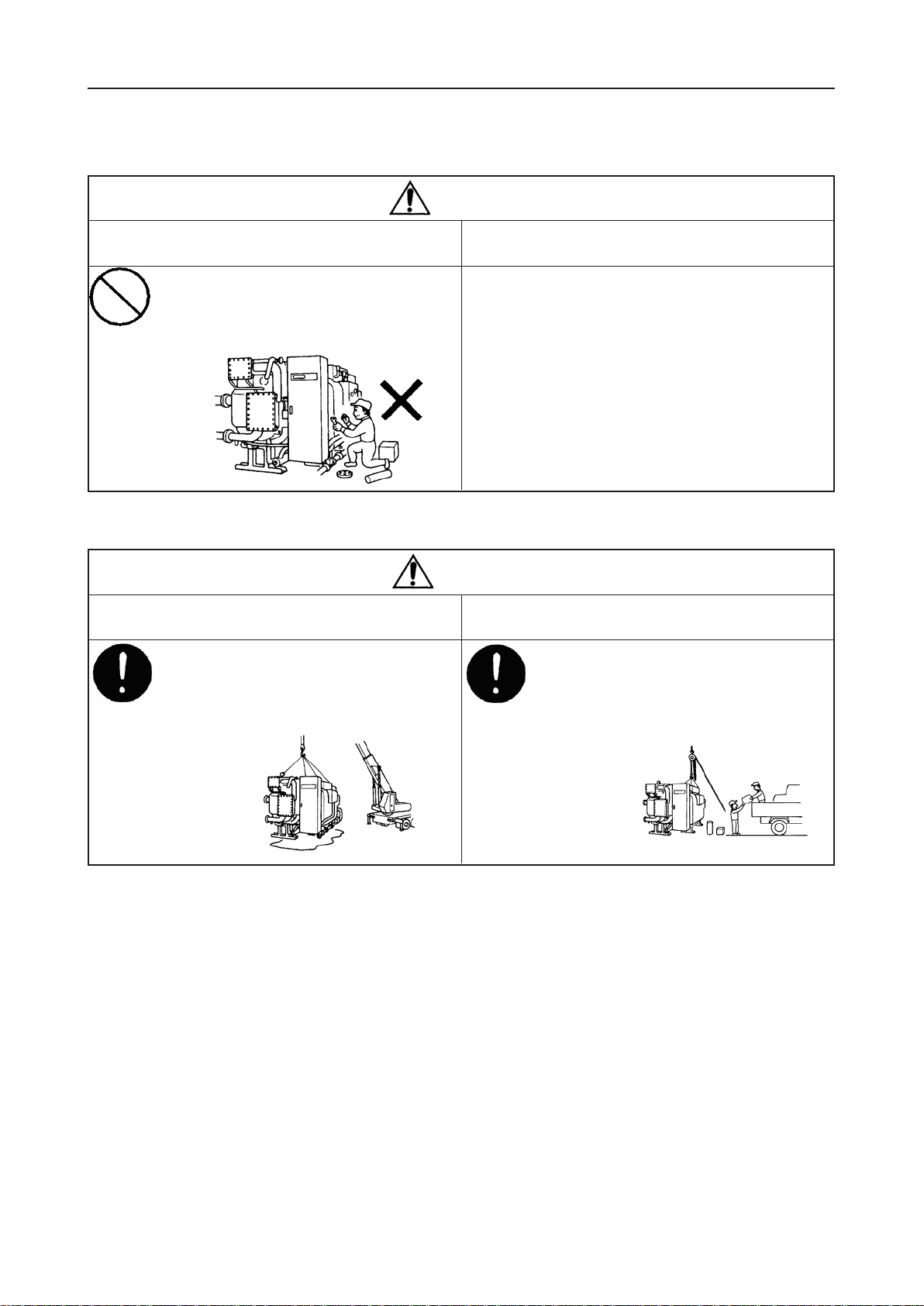

1-4. RIGGING ...................................................................................................................................... 9

1-5. SLIDING........................................................................................................................................ 9

1-6. SETTING ON THE FOUNDATION ............................................................................................... 9

1-7. LEVELING................................................................................................................................... 10

1-8. LEAK TEST, METHODOF CHARGING/DISCHARGING NITROGEN GAS ............................... 12

1-9. PIPING........................................................................................................................................ 18

1-10. FIELD WIRING ......................................................................................................................... 19

1-11. PURGING ................................................................................................................................. 20

1-12. INSULATION............................................................................................................................. 24

2. TEST OPERATION

2-1. EXTERNAL VISUAL INSPECTION............................................................................................. 25

2-2. ELECTRICAL CHECK ................................................................................................................ 26

2-3. INITIAL SETTING FOR OPERATION BOARD ........................................................................... 28

2-4. DAMPER SETTINGAND VALVE POSITION.............................................................................. 28

2-5. PURGING ................................................................................................................................... 28

2-6. FUNCTION TEST ....................................................................................................................... 29

2-7. OPERATION ............................................................................................................................... 32

CHECK LIST ........................................................................................................................................... 35

ExhibitLA........Precautions for use/Precautions for installation/FLOW DIAGRAM

ExhibitLB........Shipping dimensions

ExhibitLC........Foundation

ExhibitLE........Typical piping diagram/DIMENSIONS/RUPTURE DISK

ExhibitLF ........Field electric wiring/Wire size /ELEC WIRING DIAG/PARTS LIST

ExhibitLG .......Insulation

ExhibitLH........LiBr solution material safety data sheet

ExhibitLI .........Operation board operating instructions for confirmation of operation board parameters

ExhibitLJ ........DAMPER OPENING&VALVE POSTION