8 - INSTALLATION RECOMMENDATIONS

■Ensure sufficient devices are provided to guarantee the protection of persons and property, and to enable maintenance operations

to be carried out in complete safety.

■If a malfunction would have significant human, environmental or financial consequences, take appropriate steps to limit the effects.

■Ensure that the installation complies with the legal texts and codes in force in the country of operation, and that it complies with the

safety rules applicable to the site where it is being used (explosive atmosphere, for example).

■If necessary, affix to the machine the hazard symbol corresponding to the fluid in accordance with current standards.

■Install burn hazard signs wherever the internal temperature of pipes exceeds 65°C.

■Fit safety devices to prevent the fluid temperature or pressure from exceeding the values indicated in the order. Approval for operation

at higher conditions must be obtained from us.

■The unit must be fitted with an immediately accessible emergency stop device; this visible device must allow the electrical supply

to the unit and its accessories to be cut completely.

■Ensure that cutting off the electrical supply, whether intentionally or accidentally, does not jeopardise the process.

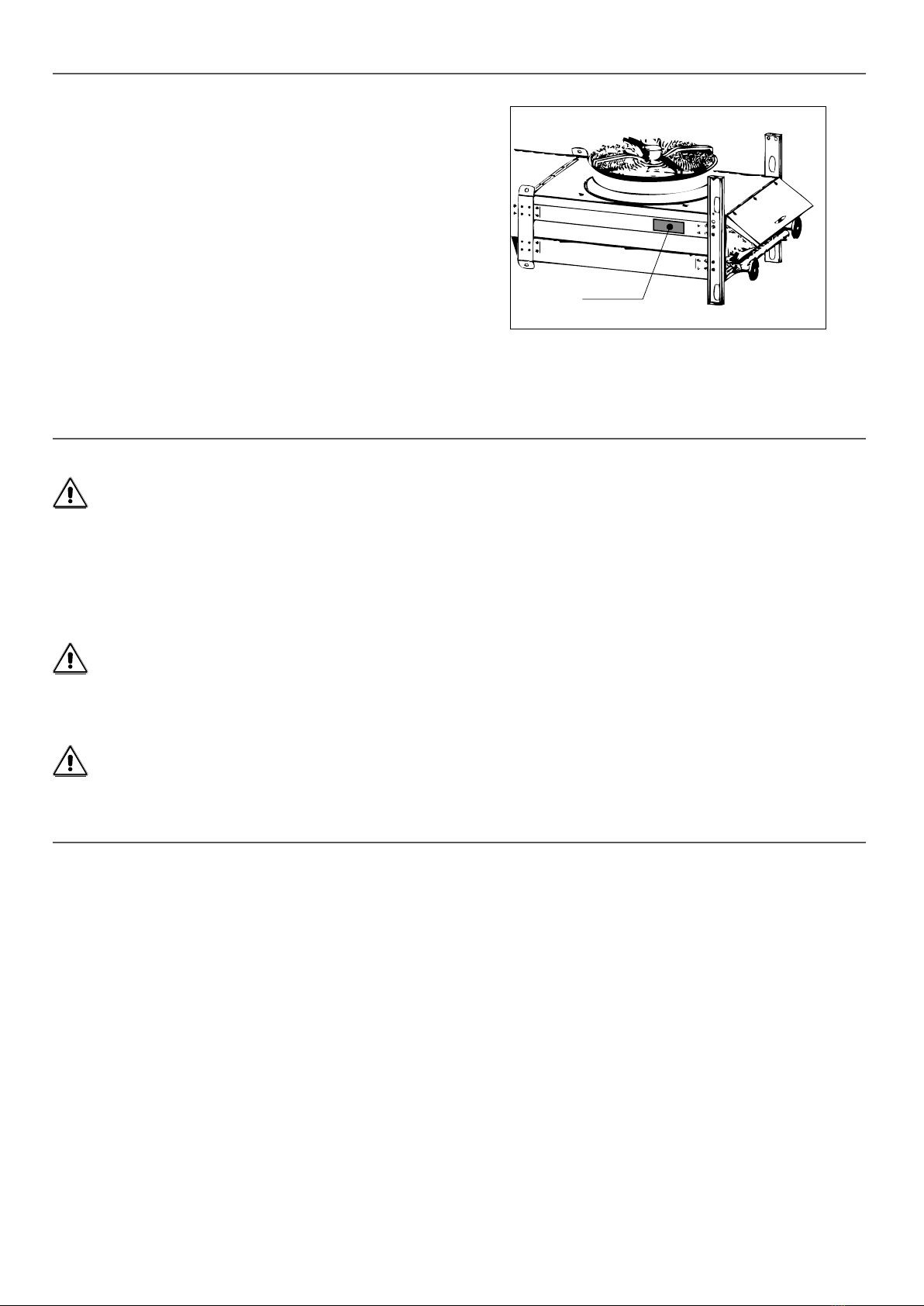

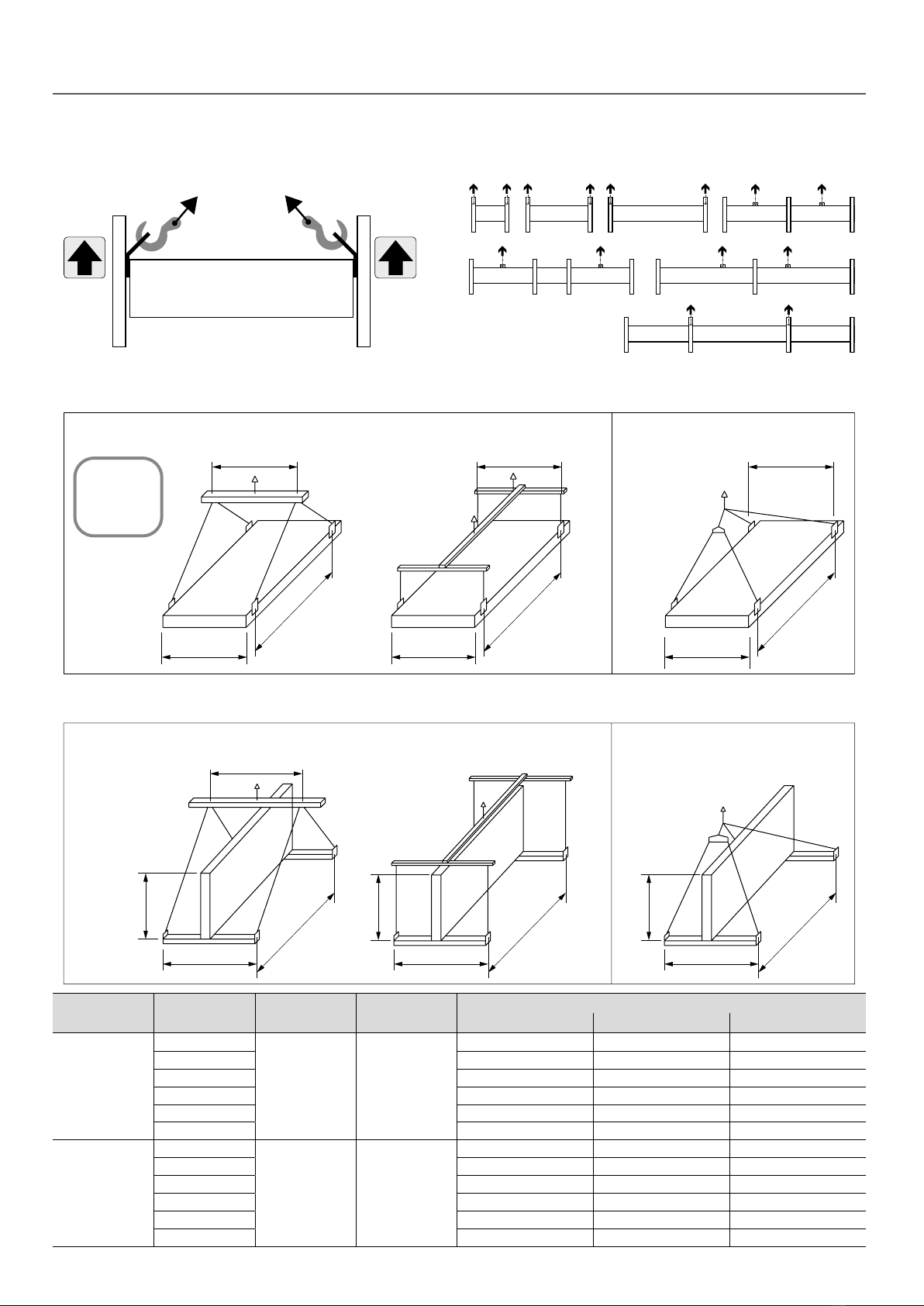

■Use the mounting holes and, if necessary, reinforce the anchoring system according to the wind conditions (particularly for vertical units).

■If the unit needs to be installed on a framework, this structure must be calculated based on the weight of the unit during operation

(full), equipped with all its accessories.

■If using rubber mounts, use a rigid frame which locks the feet together.

■If objects or hail fall on the unit, there is a risk that the finned components may be damaged (horizontal forced-draught units). Take

appropriate steps to protect it, by adding a protective screen, for example.

■If there is a risk of freezing while the system is operating, use a device designed to prevent this.

■Install venting and draining devices and shut-off valves.

■Connect the piping to earth in accordance with an overall study of the installation.

■For any accessories, refer to the specific guides.

9 - CONNECTIONS

9.1 - Electrical connection

■All wiring must be connected in accordance with the regulations that apply to the installation site (e.g. NF C 15100 in France).

■In all cases, refer to the "ELECTRICAL CONNECTIONS" document or wiring diagram attached to the unit.

■ Follow the electrical supply specications indicated on the data plate.

■The phase unbalance must not exceed ±2% for voltage.

If any of the above requirements are not met, immediately contact your energy supplier and make sure the unit is not switched on until

the necessary corrective actions have been taken. Failure to do so will automatically void the warranty.

It is your responsibility to protect the unit from mains voltage spikes and voltage spikes caused by lightning. Depending on the geographic

location and the type of mains network (buried or overhead), local regulations may require that a lightning rod be installed. Failure

to comply with the requirements of standards in force in the country of installation (e.g. NF C 15100 in France) will void the warranty.

-Before making any connection, check that the power supply cable is not powered on.

The terminal boxes on the motors for units without the terminal box or electrical cabinet option must be directly connected taking all

the necessary precautions in order to avoid:

-electrical connection errors which can damage the motors or impair performance

-water ingress in the terminal boxes (e.g. if the cover is not closed properly) which damages the motors

-people falling from a height when making electrical connections for units installed high up

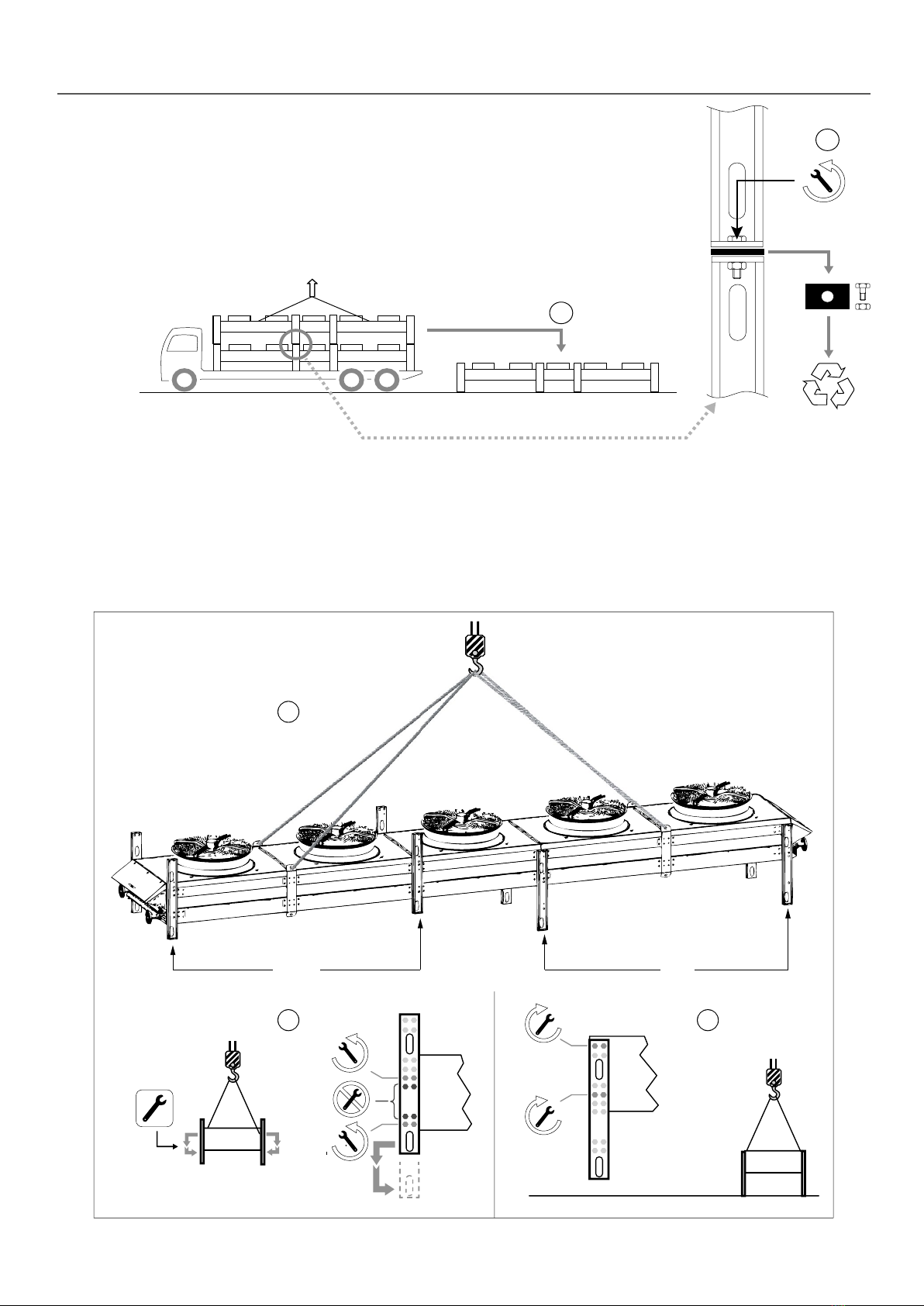

Fluid connection

■Never introduce foreign bodies into the circuit.

■The connection pipes and the regulation or insulation equipment must be set up and supported so as to ensure they do not exert

any force on the coil piping (pressure, torsion or exion). It is recommended to use exible connectors on the connections to prevent

water hammer.

■Positioning of pipes: connect all piping on the unit (see dimensional drawing)

■If brazed/welded connections are used, take appropriate precautions to ensure that welding residues do not enter the circuit.

Special note for condensers:

■Refrigerant connections: The refrigerant connections between the condenser and the internal machine, as well as the leak tests,

must be carried out by a specialist using a method in accordance with best current practices and applicable standards and

regulations. Units are delivered pre-charged with nitrogen at 0.5 bar with piping blanked.

-Blanking with brazed plugs: remove the plugs by heating them with a blowtorch

-Blanking with pressed metal: use a pipe cutter to cut off the end of the pipe no more than 10 mm from the end.

■Inlet/outlet according to stickers afxed to the manifold close to the orice.

■On grounds of hygiene, SAWING AND GRINDING ARE FORBIDDEN. Use a pipe cutter.

9.2 - Connecting a speed regulator

■ A regulator must be commissioned by a specialist, as an incorrect choice/conguration could cause electromagnetic interference

and damage to the motors. Minimum precautions:

-Use a shielded cable upstream and downstream of the regulator.

-The frequency must be between 25 and 50 Hz.

-Fit a DU/DT filter between the speed regulator and the fans.

10