Make Piping Connections -- Access to piping is

available throughthe accesspanels at the front, top, or end of

the vertical unit (horizontal accessfrom bottomor side). Route

piping through the pipe tunnel or the unit's back panel or floor

panel. Metal blank-off panels must be trimmed to complete

piping installation. All piping connections must be performed

by qualified personnel in accordance with local and national

codes.

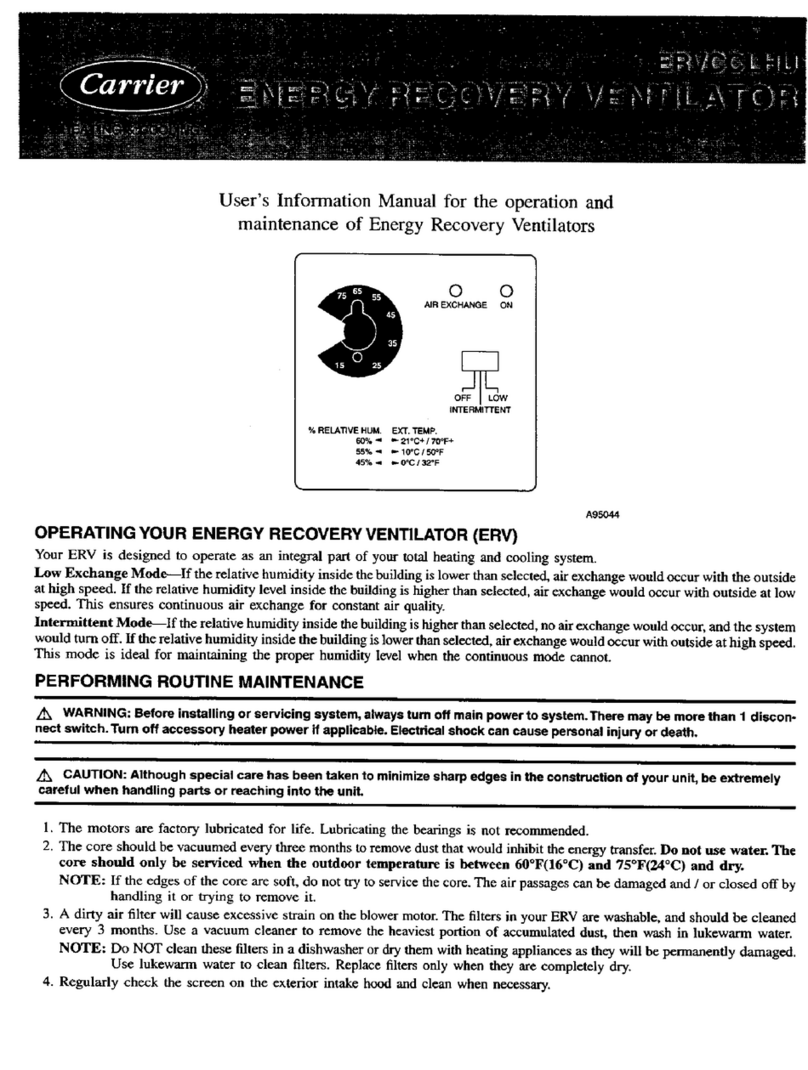

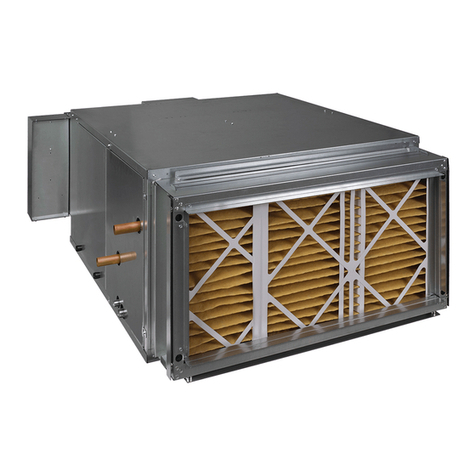

DRAIN CONNECTIONS -- Condensate drain connections

are located on each end of the drain pan near the bottom of the

unit. Condensate drain line must be 3/4 in. copper tubing,

galvanized pipe, PVC or similar plastic pipe. Install drain line

maccordance with all applicable codes. Insulate the drain

line to prevent sweating. See Fig. 6for typical drain trap

construction.

Units with cooling coils require traps to prevent air from

entering the condensate fitting and preventing proper drainage.

Drain must flow downhill from the unit a minimum of Vs in.

per ft_Drain must be free and clear at all times.

3/4"

PVC OR COPPER 3/4=

GALVANIZED PiPE

3" MIN

2" MIN

Fig. 6 -- Typical Condensate Drain Trap

Construction

EQUAL[ZER

SENSING BULB (CLAMPED TO

SUCTION LINE AND INSULATEDI

SUCTION LINE

Insulate drain lines to prevent condensate. Care must be

taken to avoid interference with control panel on left side

drain. LIQUID LINE

WATER SUPPLY/RETURN CONNECTIONS -- Install pip-

mg in accordance with all applicable codes. All piping must be

supported separately from coils.

Water supply must be connected so thatentering water is on

leaving-air side of coil. See the connection labels on the unit to

locate the inlet. Coils must be adequately vented to prevent air

binding. Be sure valves are in proper operating position and are

easily accessible for adjustment.

If coil and valve package connections will be made with a

solder joint, care should be taken to ensure that components in

the valve package are not subjected to high temperatures winch

may damage seals or other materials. Many 2-position electric

control valves are provided with a manual operating lever. This

lever should be in the OPEN position during all soldering

operations.

If coil connection is made with a union, the coil side of the

union must be prevented from taming (it must be backed up)

during tightening. Do not overtighten! Overaghtening will dis-

tort (egg shape) the union seal surface and destroy the unior_

NOTE: A freezestat is factory-installed when a hot water/steam

coil is installed.

STEAM CONNECTIONS -- On units with steam heating

coils, the maximum steam pressure applied to the unit should

never exceed 10 psig (operating pressure 6 psig).

DIRECT EXPANSION REFRIGERANT PIPING -- Use the

condensing unit manufacturer's recomrt_nded line sizes and

requirements. Perform leak test using nitrogen. Evacuate and

charge per recommended heating, ventilation, and air condi-

tioning (HVAC) procedures and all applicable codes. Insulate

suction hne after leak test up to the coil section end plate for

correct operation and to eliminate sweating. Use refrigerant-

grade copper lines only. The unit is NOT to be applied as a

heat pump.

See Fig. 7 for refrigerant piping connections with recom-

mended locations for the thermostatic expansion valve (TXV)

and sensing bulb.

HYDRONIC COIL PIPING -- When all joints am complete,

perform hydrostatic test for leaks. Vent all coils at this time.

Check interior unit piping for signs of leakage from shipping

damage or mishandling. If leaks are found, notify a Cartier

representative before initiating any repatrs. Release trapped air

from system (refer to Make Final Preparations section).

NOTE:FollowTXVmanufacturer'sinstructions.

Fig. 7 -- Typical TXV (Thermostatic Expansion

Valve) Installation

All water coils must be protected from freezing after initial

filling with water. Even if system is drained, unit coils may

still have enough remaining water to cause damage when

exposed to temperatmes below freezing.

Following the hydrostatic test, insulate all piping up to the

coil section end plate to prevent sweating.

To ensure compliance with building codes, restore the struc-

ture's original fire resistance rating by sealing all holes with

material carrying the same fire rating as the structure.

Make Electrical Connections -- Refer to unit serial

plate for required supply voltage, fan and heater amperage and

required circuit ampacities. Refer to unit wiring diagram for

unit and field wiring. See Tables 2M.for electrical data.

All input power wiring connections are accessed through

the electrical panel on front right-hand side of the unit. Use the

openings that am for the piping connections. See the dimen-

sional drawings Fig. 1-5 for electrical box connections.

The fan motor should never be controlled by any wiring or

device other than the factory-supplied switch or thermostat/

switch combination unless prior factory authorization is ob-

tained. Fan motor may be temporarily wired for use during

construction only with prior factory approval and only in strict

accordance with the instructions issued at that time.

All electrical connections should be made by qualified per-

sonnel and be in accordance with governing codes and ordinanc-

es. Any modification of unit wiring without factory authorization

will invalidate all factor 3,warranties and nullify any agency list-

ings. See Fig. 8A and 8B for typical wiring connections for basic

unit without CCN (Carder Comfort Networlc_) controls.

Actuators (Field-Supplied) -- Field-supplied actuators

must be mounted on 1/2in.diameter damper shafts.