Immersion Temperature Sensors

Installation and

Specifications subject to change without notice.

Catalog No. 11-808-632-01

#20907 – 2/20/19

Thermowells (continued…)

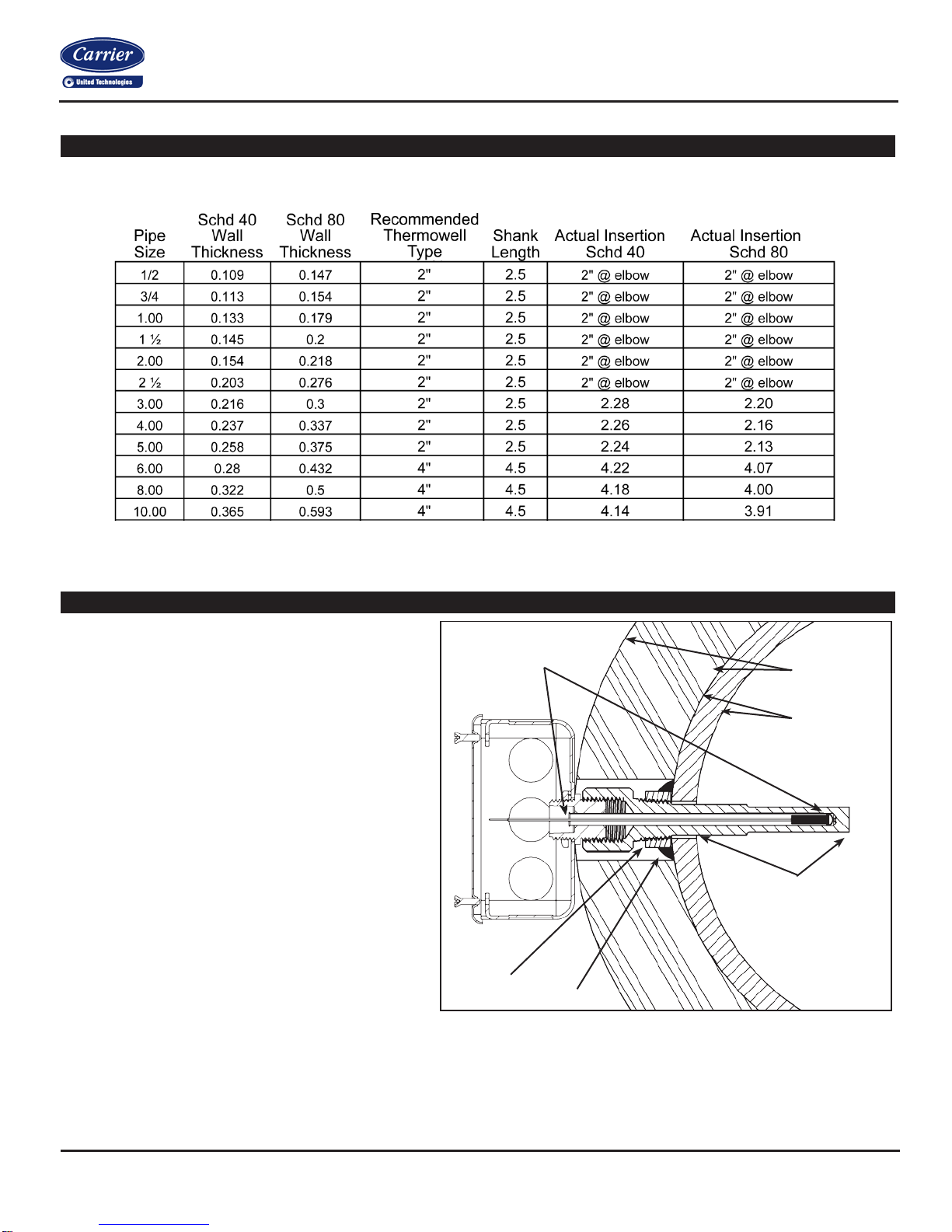

Choosing the correct Thermowell

As part of our ZS Sensor line, Carrier sells 2.5” and 4.5” machined thermowells made of Brass or 304 Stainless Steel (SS) and two-

part welded thermowells made of 304 Stainless Steel. The two-part welded thermowells are not as strong as their machined

counterparts. Carrier recommends the use of welded thermowells be limited to small diameter systems in low vibration environments.

Carrier strongly encourages that single-piece machined thermowells be used when possible. See the entries for Welded SS in the

following design tables. Additionally, weldedstainless steel thermowells should not be used in turbulent flow; ideally they should be

three to five pipe diameters from elbows or transitions.

Table 2: Maximum Fluid Velocity versus Insertion Length

The values shown in Table 3 are based

on operating temperatures of 350ºF for

brass and 1000ºF for stainless steel.

Slightly higher velocities are possible at

lower temperatures.

Thermowell

Material Fluid Type

Insertion Length (inches)

Maximum Fluid Velocity (Feet per second)

Brass

Welded

304 SS

304 SS

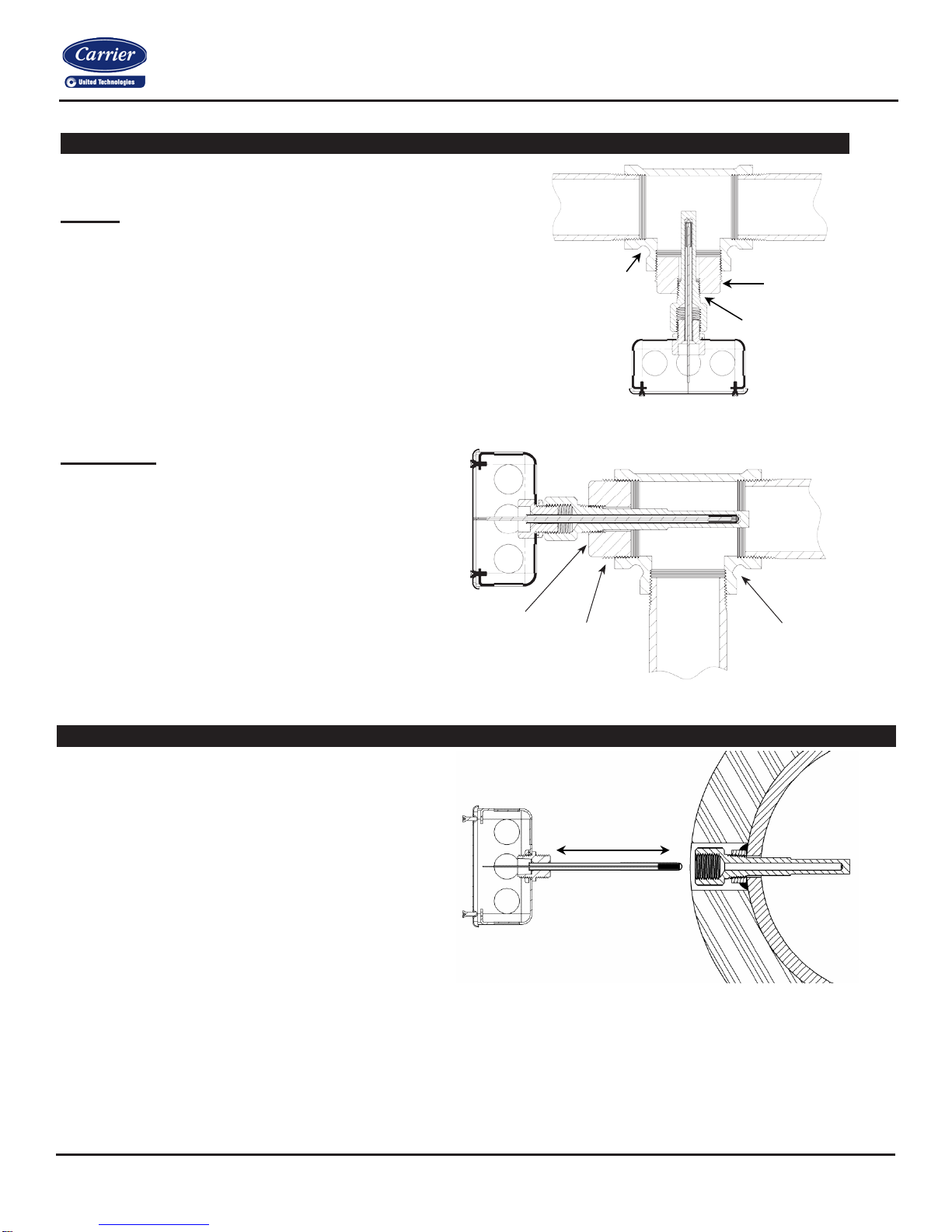

Comparing the Wake Frequency and the Resonant Frequency

Table 2 and Table 3 were developed to insure that there will be no thermowell failures due to application stresses. Thermowell

failures, in most cases, are not due to the effects of pressure or temperature on the well. The calculations necessary to provide

adequate strength, under given conditions, are familiar enough to permit proper choice of wall thickness and material. The values

shown in Table 2 are conservative, and intended primarily as a guide.

Less familiar, and more dangerous, are the vibration effects to which thermowells are subjected. Fluid, flowing by the well, forms a

turbulent wake (called the Von Karman Trail) which has a definite frequency, based on the diameter of the thermowell and the velocity

of the fluid. It is important that the thermowell have sufficient stiffness so that the wake frequency will never equal the resonant (natural)

frequency of the thermowell itself.

If the resonant frequency of the thermowell coincided with the wake frequency, the thermowell would vibrate to destruction and break

off in the piping. Thermowells are also safe if the resonant frequency below the wake frequency or if the fluid velocity is constantly

fluctuating through the critical velocity point. Nevertheless, if the installation is not hampered by the use of a sufficiently stiff thermowell,

Carrier recommends the values given in Table 3 not be exceeded.

Table 1: Pressure Rating versus Temperature

Thermowell

Material

Temperature in Degrees Fahrenheit

Pressure Rating (Pounds per Square Inch)