2132/2116 Overtemperature Controller

6 MC11 –1.05

note: the following sections apply only when overtemperature control is fitted

42132 &2116 –DESCRIPTION

The model 2132 and 2116 overtemperature controllers are made by Eurotherm, and are fitted by

Carbolite Gero configured for immediate use. They are digital instruments with a latching alarm,

requiring no additional panel controls for its use. The instruments are similar in function, but the

2116 is physically larger.

The controllers feature easy setting of overtemperature setpoint, and reading of current

temperature at the overtemperature sensor.

They do not contain a real-time calendar, and are not subject to century-end date problems.

To operate the controller there must be power to the furnace or oven, and the Instrument switch

must be on. If a time switch is included in the furnace or oven circuit, this must be in an On

period.

When an overtemperature condition occurs, the controller cuts the power to a contactor, which in

turn cuts power to the heating elements. Power is not restored until the controller is “reset”.

Other components do not generally have power to them cut on overtemperature; oven fans

usually remain running, but may not do so if other options (such as a door switch) are fitted.

52132 &2116 –OPERATION

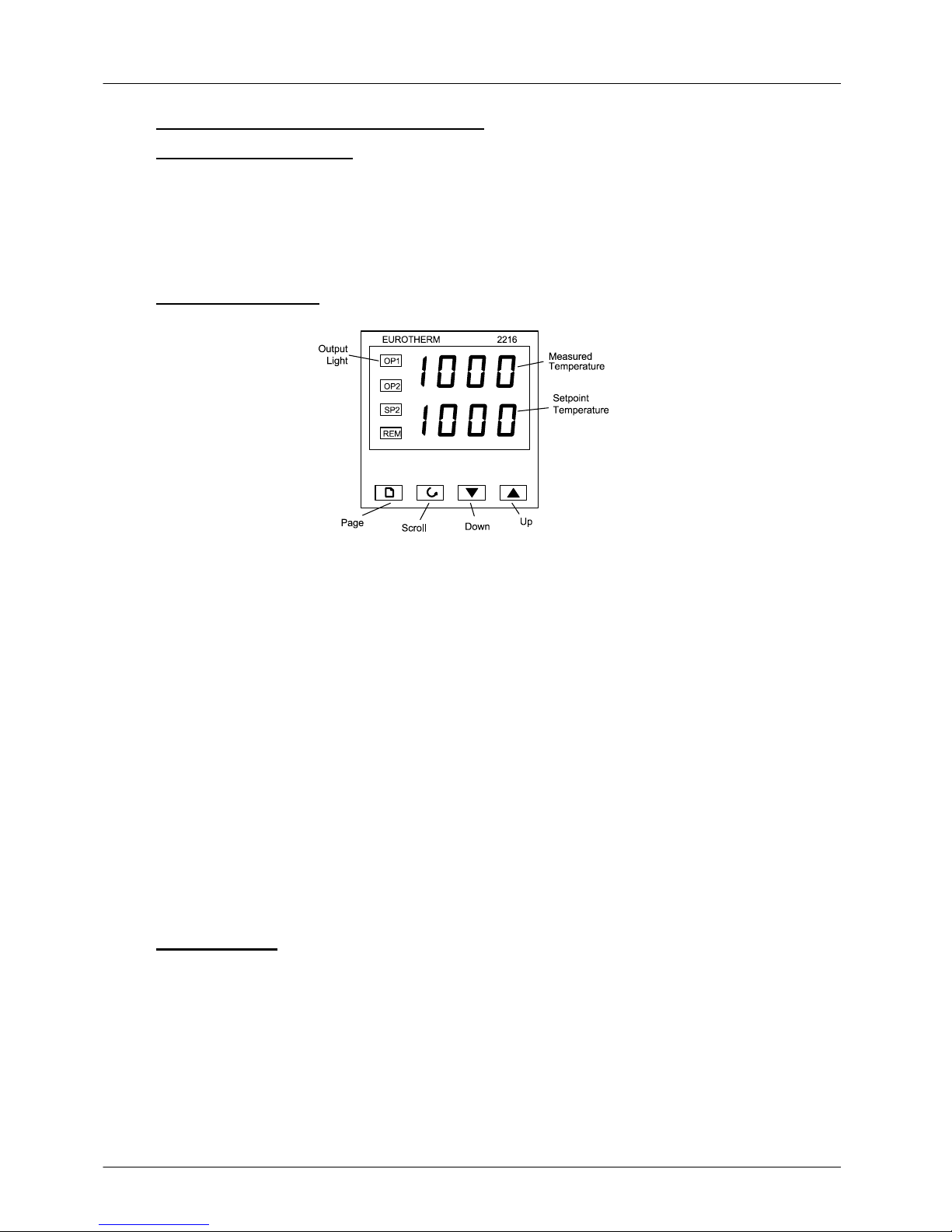

When switched on, the controller lights up, goes through a short test routine, and then displays

the measured temperature or the overtemperature setpoint.

The Page key allows access to parameter lists within the controller; most lists and parameters

are hidden and cannot be accessed by the operator because they contain factory-set parameters

which should not be changed.

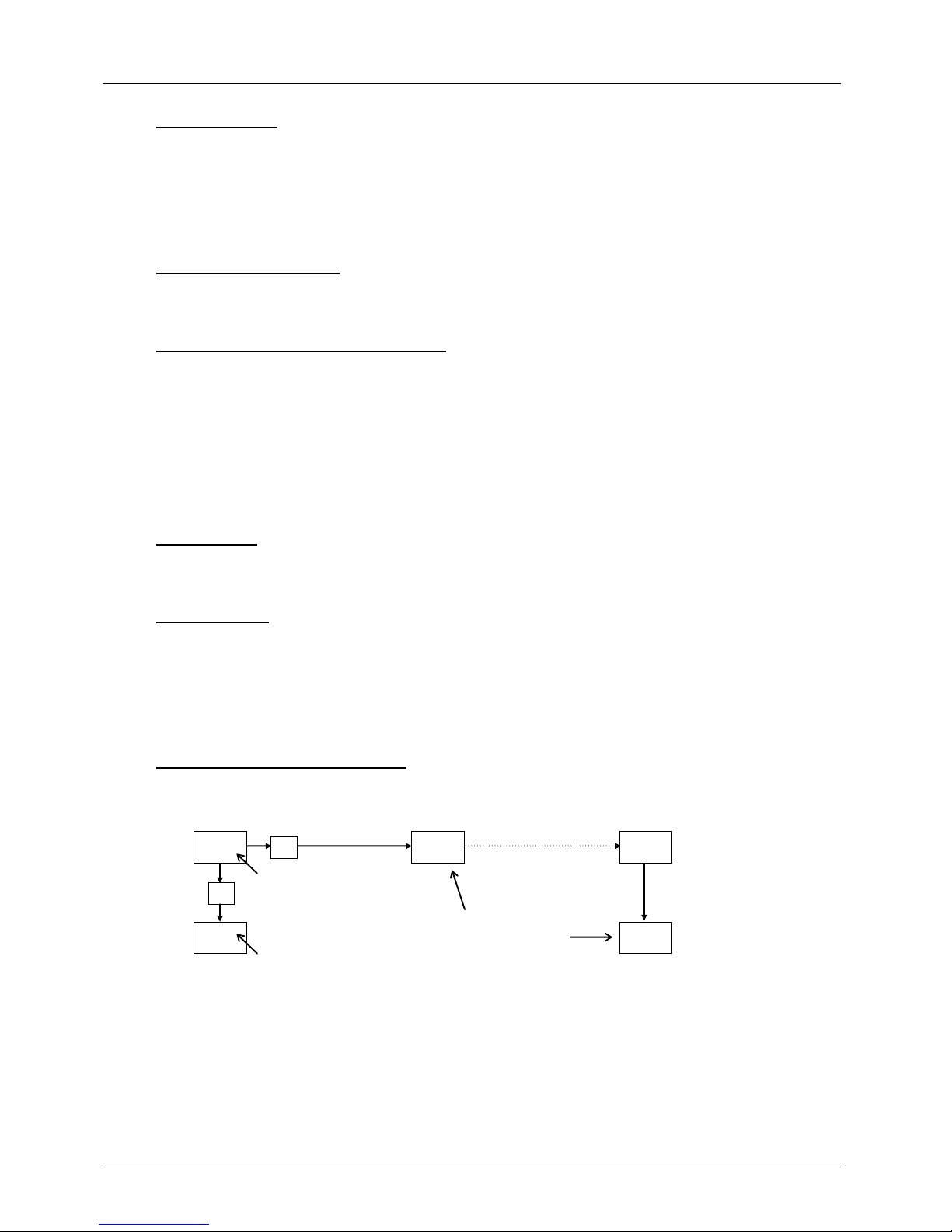

A single press of the page key displays the temperature units, normally set to °C; further

presses reveal the lists indicated in the Navigation Diagram in section 5.6.

The Scroll key allows access to the parameters within a list. Some parameters are display-

only; others may be altered by the operator.

A single press of the scroll key in the Home list displays the temperature units; further presses

reveal the parameters in the current list indicated in the Navigation Diagram.

To return to the Home list at any time, press Page and Scroll together, or wait for 45

seconds.

The Down and Up keys are used to alter the setpoint or other parameter values.