6072554-R0

7

100-Hour Maintenance

Every time the lift truck is serviced or every 100 hours

of truck operation, whichever comes first, complete the

following maintenance:

• Check for loose or missing bolts.

500-Hour Maintenance

After each 500 hours of truck operation, in addition to the

100-hour maintenance, perform the following procedures:

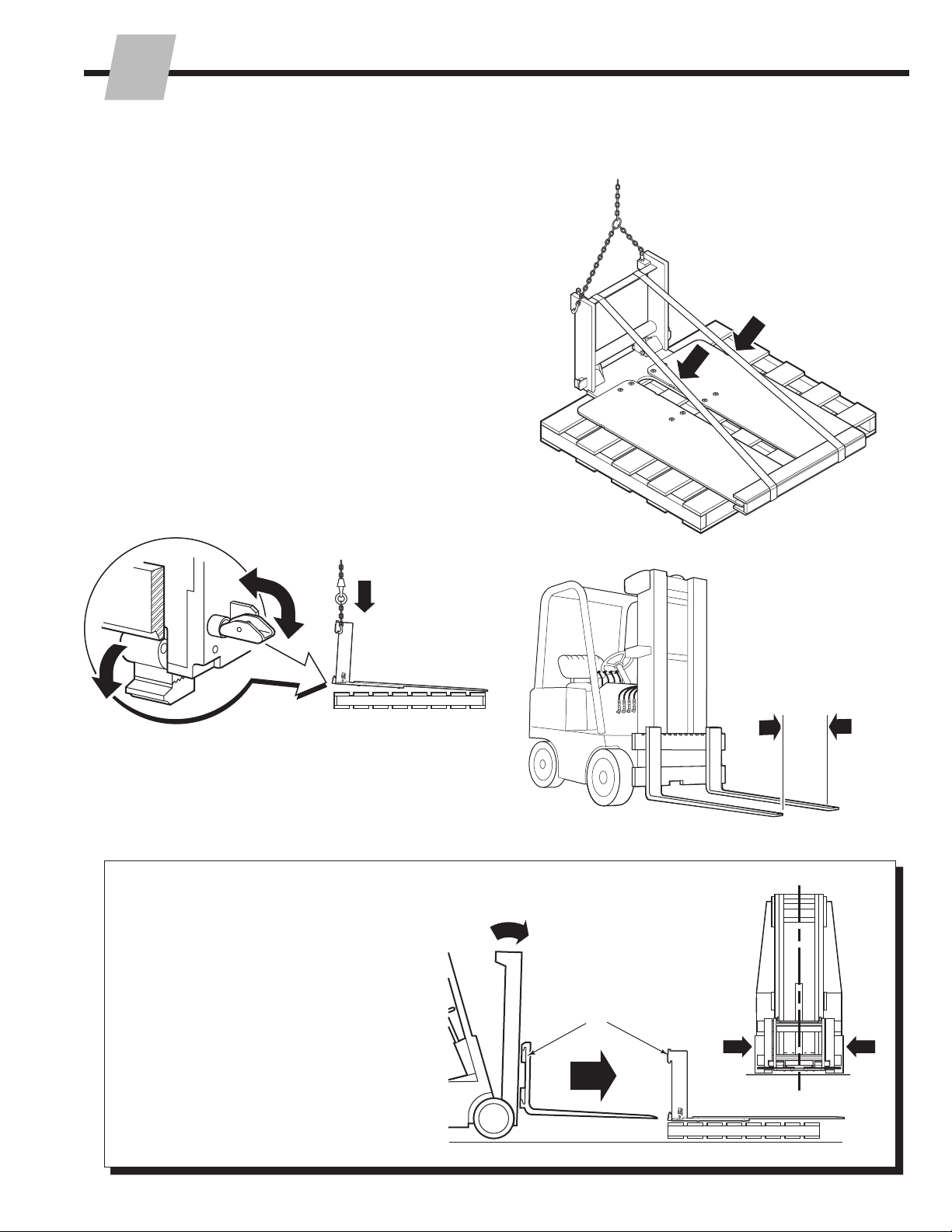

Dedicated Scooping Platens

• Tighten the upper mounting hook capscrews to 120 ft.-

lbs. (165 Nm).

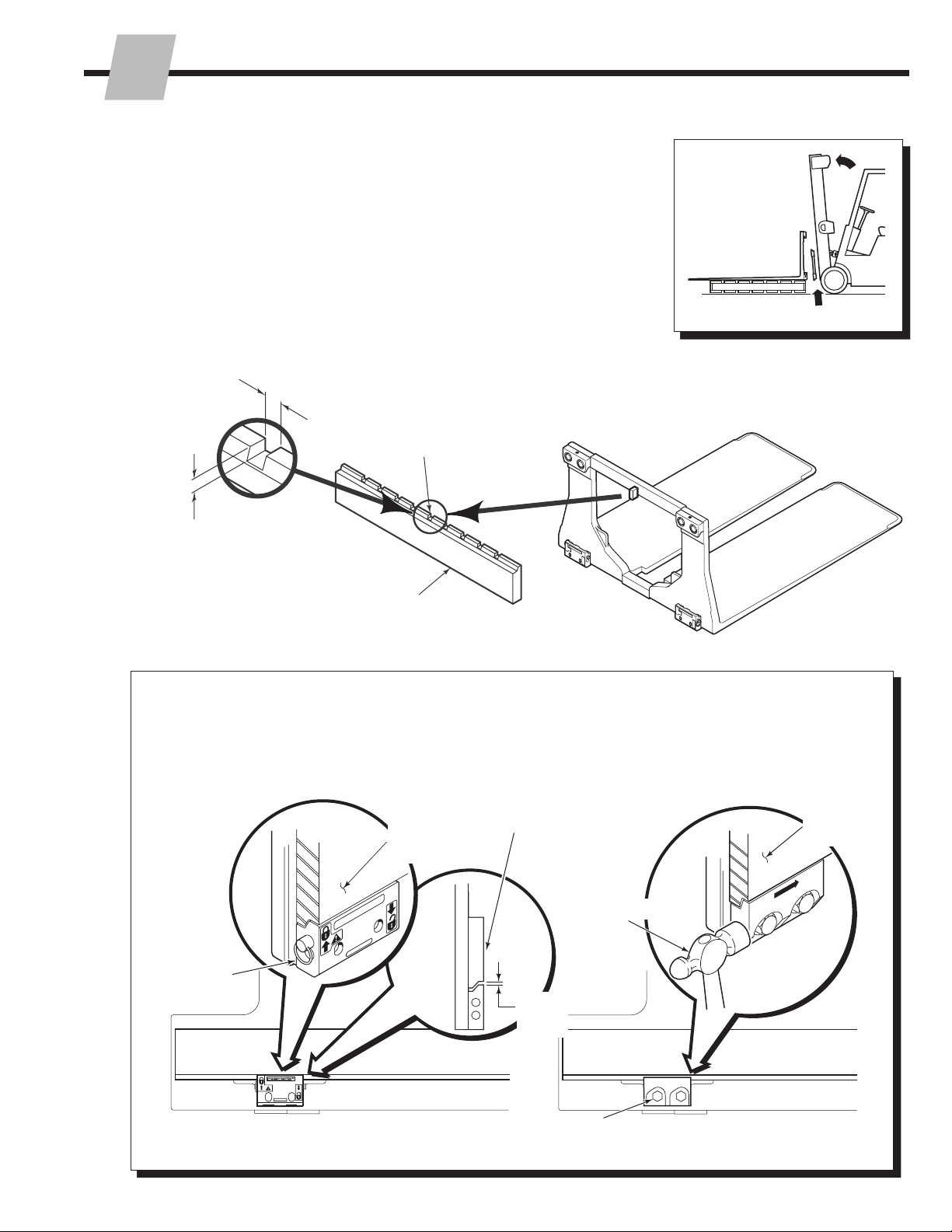

• Check the clearance between the lower mounting hooks

and the truck carriage bar:

Quick-Change Hooks – 3/16 in. (5 mm) maximum.

Bolt-on Hooks – Tight against lower carriage bar.

• If hook adjustment is necessary, refer to Dedicated

Installation Step 3 (pg. 5) or 5 (pg. 6) in this Manual.

Tighten the lower hook mounting capscrews to 120 ft.-

lbs. (165 Nm).

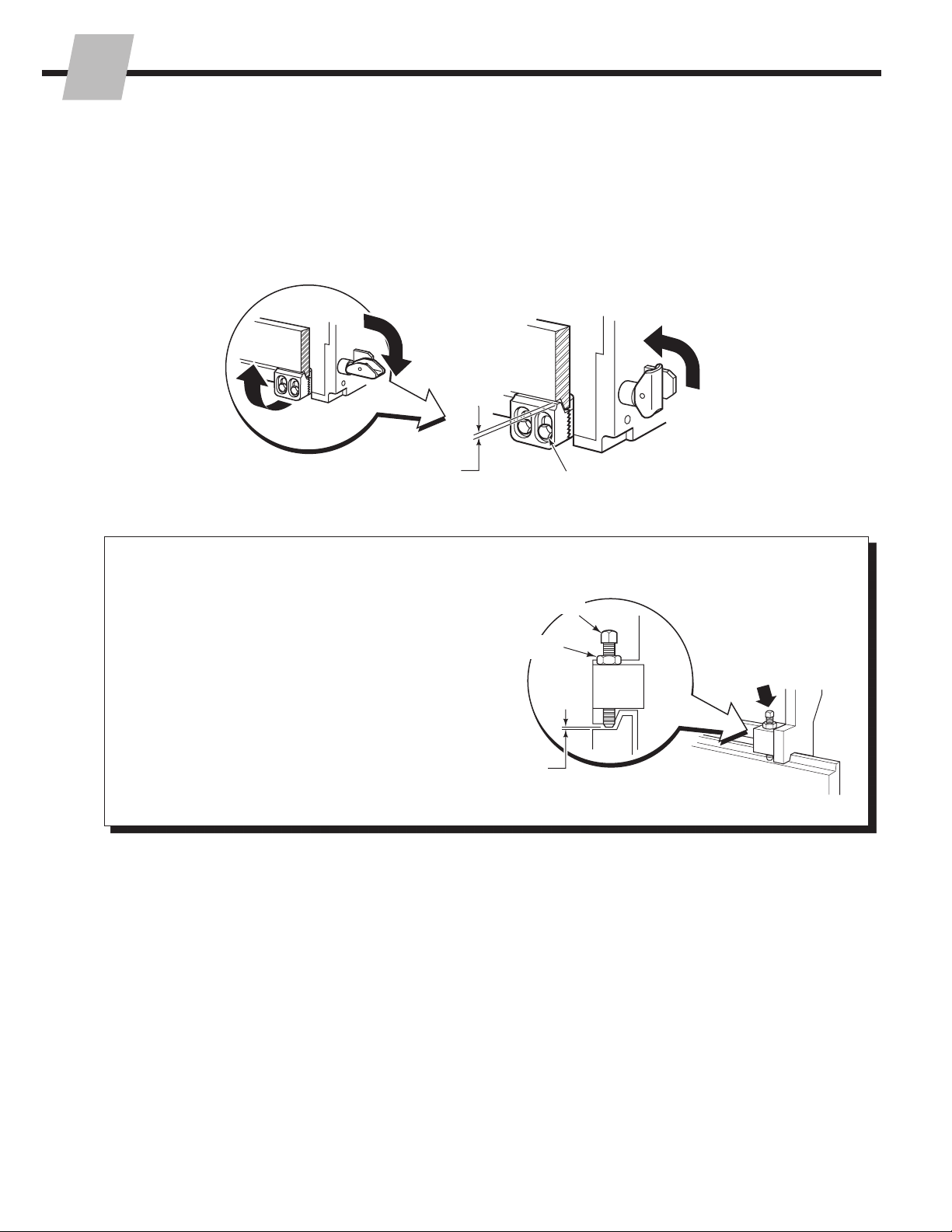

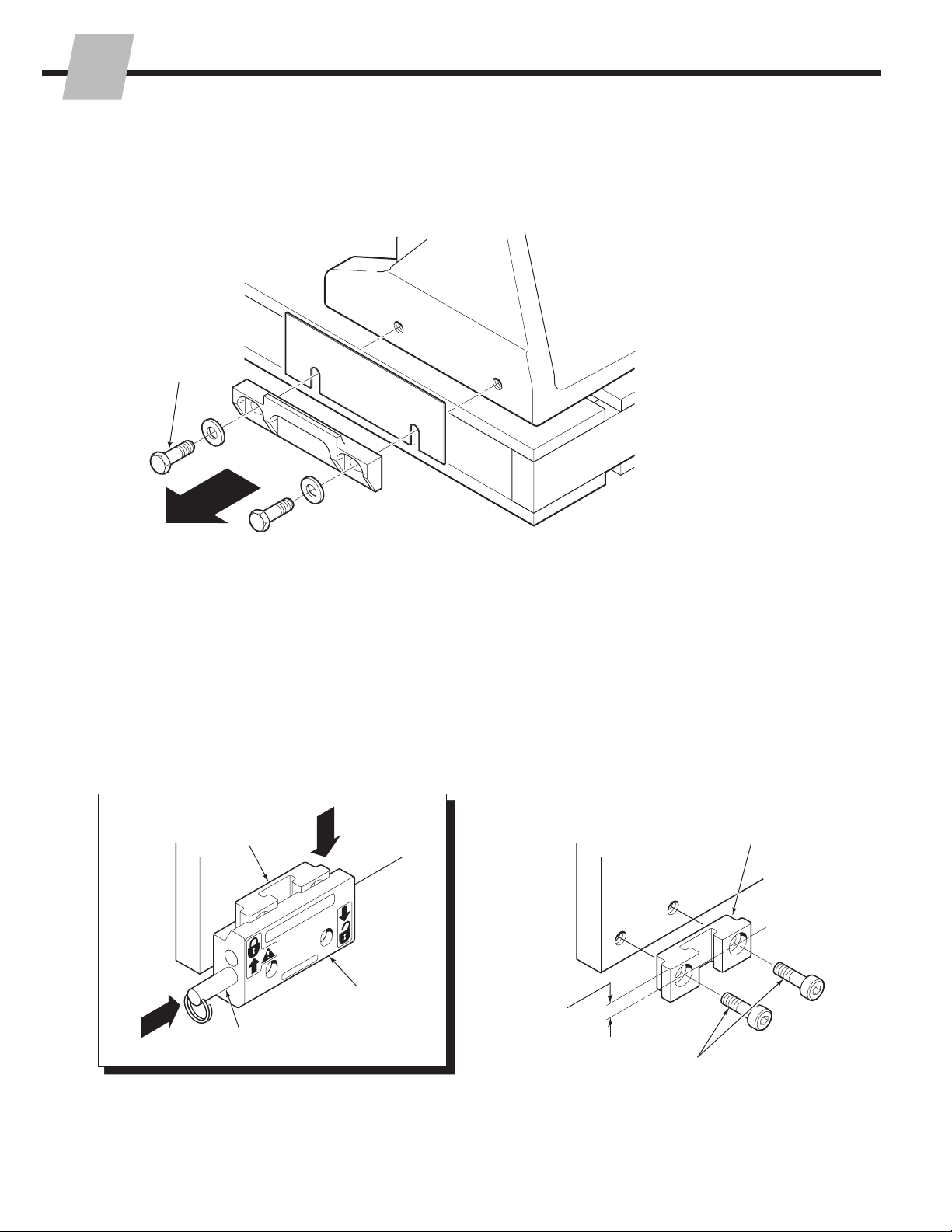

QFM™ Scooping Platens

• Tighten the platen mounting capscrews to 40 ft.-lbs.

(60 Nm).

• Check for 1/8 in. (3.2 mm) maximum clearance between

lower mounting hooks and truck carriage bar. Refer to

Step 5 in this manual if adjustment is necessary.

• Check for 1/16 in. (1.6 mm) maximum clearance

between upper hook setscrews and truck carriage bar.

Refer to Step 6 in this manual if adjustment is necessary.

• Tighten lower hook capscrews to 52 ft.-lbs. (70 Nm).

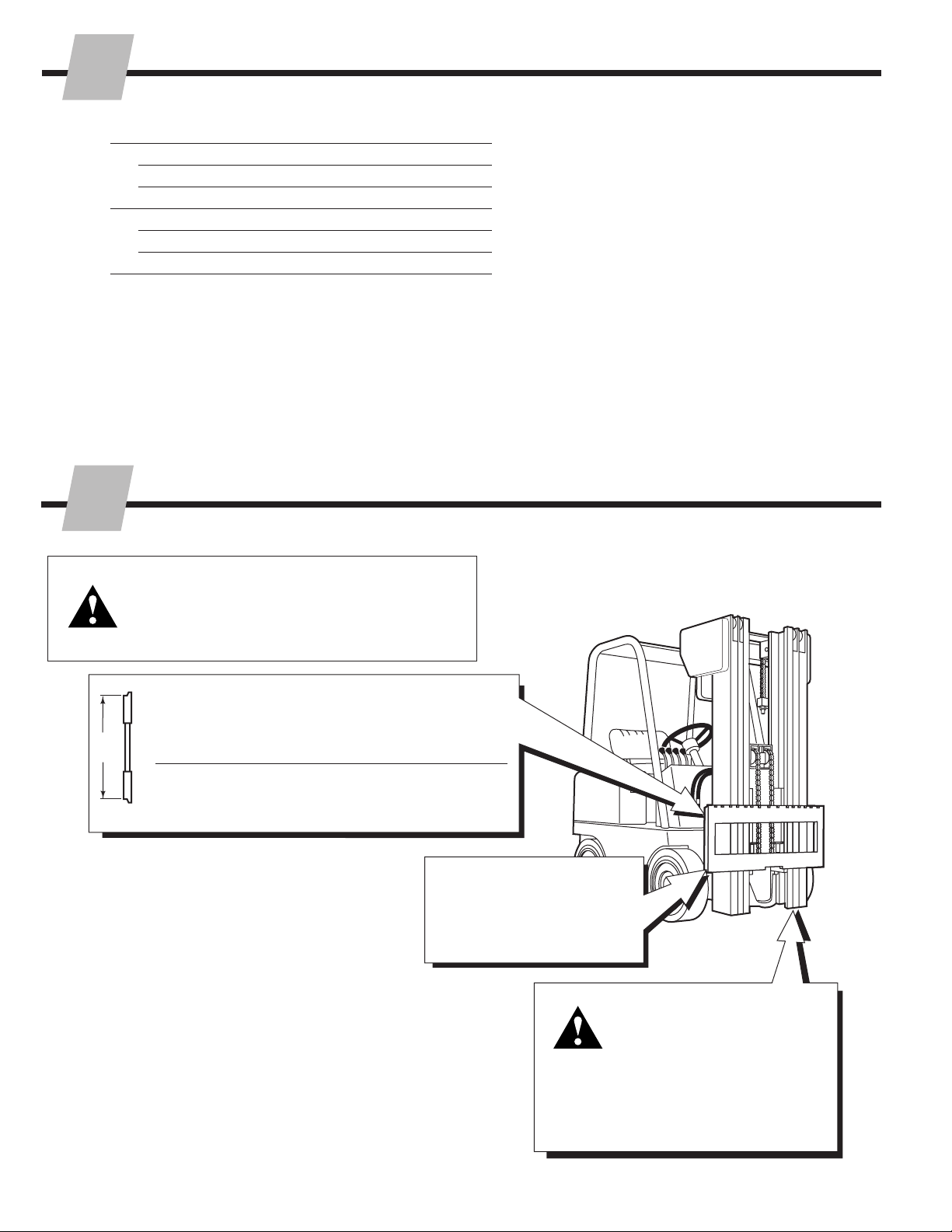

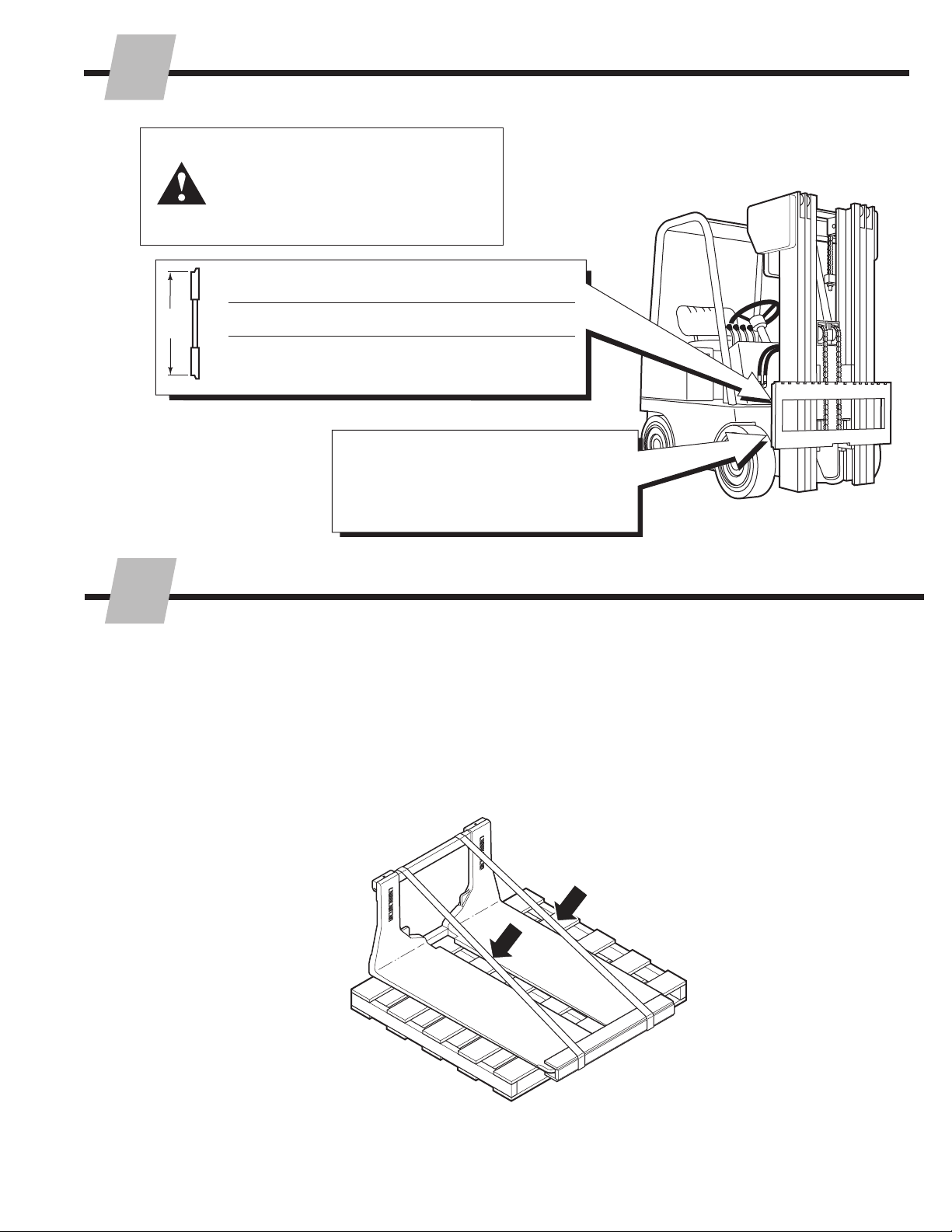

WARNING: Platen capscrews must be

tightened regularly to prevent equipment

damage or personnel injury.

Quick-Change

Lower Hooks

PERIODIC MAINTENANCE

Upper Mounting

Hook Capscrews

Lower Mounting

Hook Capscrews

Upper

Hook

Setscrews

Lower Mounting

Hook Capscrews

Platen

Mounting

Capscrews

Upper Mounting

Hook Capscrews

Lower Mounting

Hook Capscrews

Bolt-On Lower

Hooks

QFM™ Scooping Platens

Dedicated Scooping Platens