Introduction............................................................................................... 1

Using the Manual.................................................................................... 1

Notes Before Use ................................................................................... 1

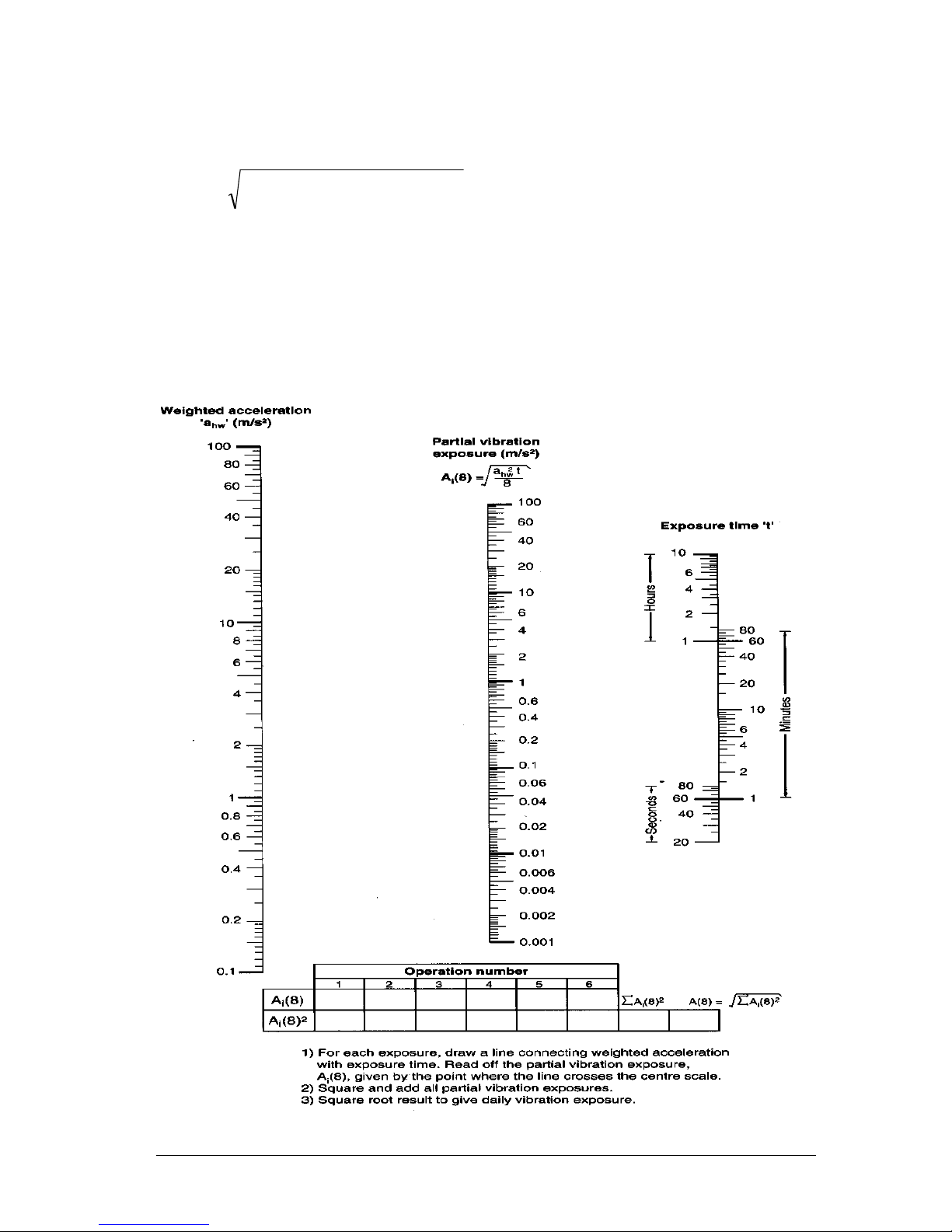

Measuring Vibration.............................................................................. 2

Hand ARM (HARM) Vibration Direction .............................................................. 4

Transducer Mounting................................................................................................... 4

Vibration Level.................................................................................................................. 5

Frequency Weighting.................................................................................................... 5

Battery Installation / Check............................................................... 7

Fitting the Accelerometer ................................................................... 7

Switching the Instrument On & Off.................................................. 8

(Status) Button........................................................................................ 8

(Parameter) Buttons............................................................................. 9

Changing or Viewing Instrument Settings ................................. 10

Setup Screen.................................................................................................................10

Detector .......................................................................................................................10

Parameter...................................................................................................................11

Filter ...............................................................................................................................12

Range ............................................................................................................................12

Viewing the Setup Screen .......................................................................................12

Changing Settings within the Setup Screen ...................................................12

Storing Data .......................................................................................... 13

Reviewing/Clearing Stored Data................................................... 13

Viewing Data ..................................................................................................................13

Clearing Data.................................................................................................................14

Calibration .............................................................................................. 14

Warranty and After Sales Service................................................ 15

EC Declaration of Conformity.......................................................... 16

Technical Specifications.................................................................... 17

Accessories............................................................................................ 18

Instrument Disposal ........................................................................... 18

Instrument Details .............................................................................. 19

Disclaimer............................................................................................... 19