5

12.Machine does not use for a long time, before defending machine or before changi-

ng bit, please pull out the plug of power source.

13.Cannot stay in the spanner of handling bit bit is above, before starting machine,

ensure that spanner has left bit.

14.Avoid accident start machine. When moving to put through the machine of power

source , cannot put finger on switch. Ensure that before plug is being inserted into

socket, machine switch is in the location that stops.

15.In outdoor manipulator ware, please use the cable of extension line that accords

with safe requirement.

16.In unit process of cargo bandling must notice concentration, do not when excessi-

veness tiredness, after wine, finish drill with the condition of taking medicine to

make tool.

17.The type of generator speed adjustment or gear speed adjustment in work please

select the adaptive bit of appearance, and open speed most quickly, so machine

reach best state. If rig in working process rock , must close machine to inspect the

concentric degree of bit and main shaft , can damage machine otherwise to occur

danger.

18.Pay attention: For your personal benefit, please choose original factory accessory

Is not original factory accessory if choosing , will may produce injury for operator

or the very machine.

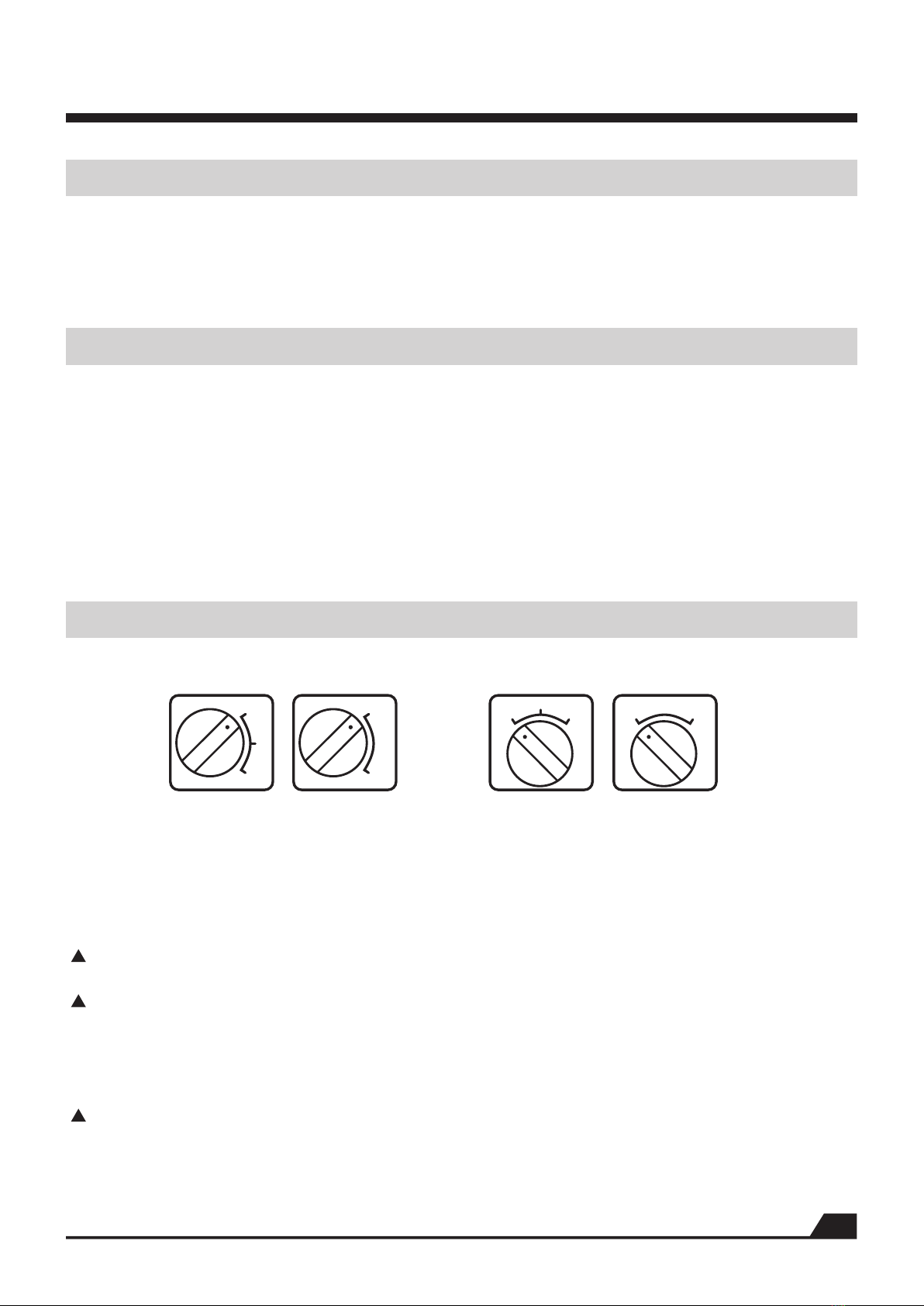

Follow the steps to installing and connecting.You can use additional tool .To

complete the following work.

Pay attention: Before joining , must guarantee that the switch of main

computer is in the state that stops.

Step 1: Comparing with the inspection of container load plan, machine and parts

open package, inspect machine in transportation process, whether damage ,

inspection the voltage of building site whether the voltage that shows on nameplate

is consistent, contrast container load plan sees the attachment in package whether is

complete.

Step 2: Power source joins , according to a standard EN61029 and a IEC1029-2 6

of European Union, taking the diamond drilling machine of water schoolwork must

add to pack the protector of leakage of electricity ,the socket of power source must

carry out earthing. It is consistent with these safe rules, our product matches have

packed the protector of leakage of electricity, its function ,including leakage of

electricity are protected untie with under-voltage to deduct. Insert the plug of power

source well after, the switch face plate of the protector of leakage of electricity must

ensure that is in ON ( beginning ) location.Fall if arising voltage drop, the protector

of leakage of electricity will automatic everything breaks , once after voltage normal,

should operate the protector of leakage of electricity again in REST cubes ( reset )

location. The protector of leakage of electricity specified movement current is 30mA.

Pay attention: Quote clean source of water surely , contain grit waiting for until

the water of impurity may damage the water set sealing ring of machine, 3biggest

hydraulic pressure is 3BAR.

PREPARATORY STAGE