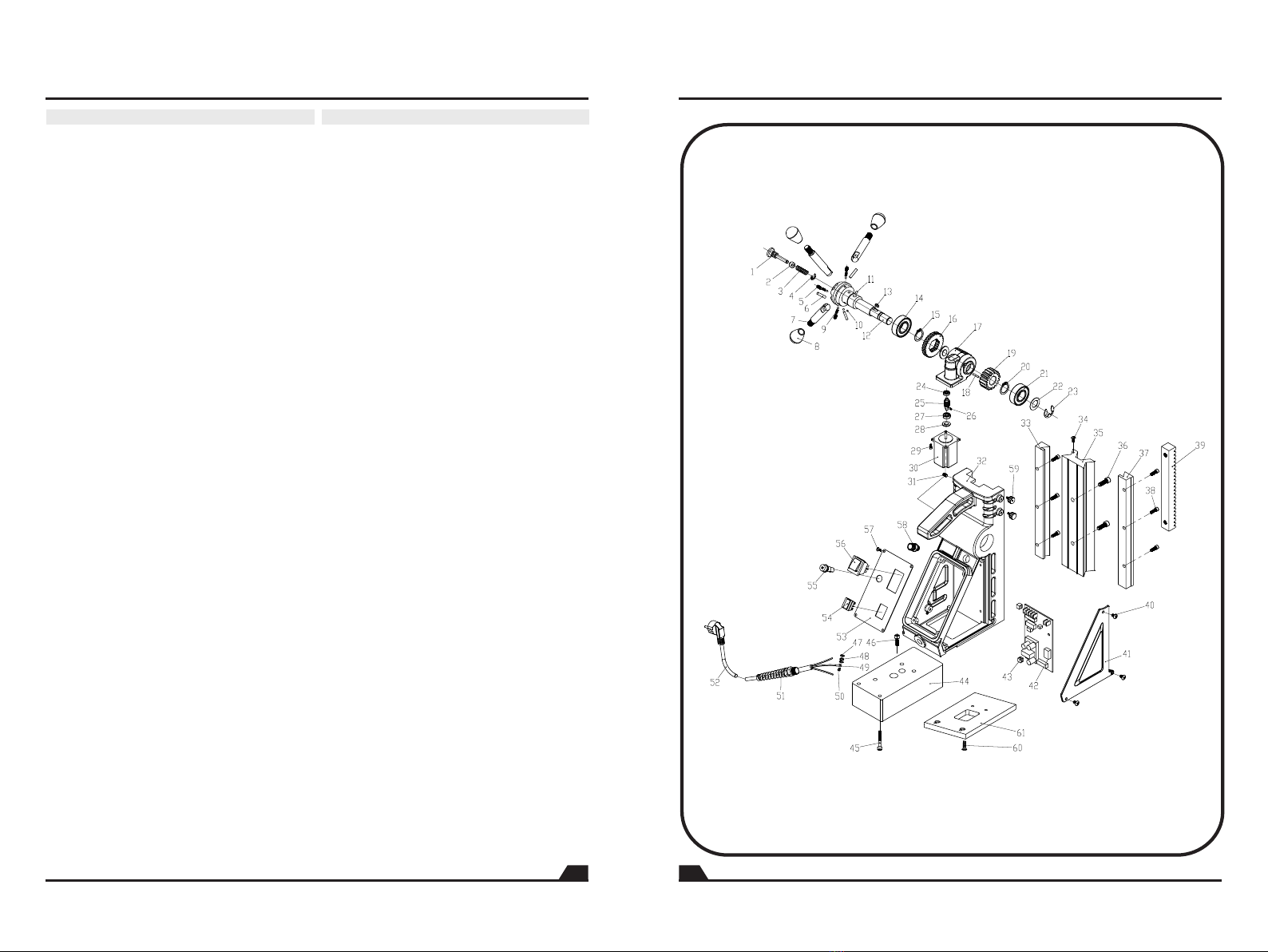

34

You receive a completely assembled Magnetic Core Drilling Machine and detailed operating

manual. Please check the condition of the goods on receipt for any transport damage, and make

sure the delivery is complete. Otherwise contact the manufacturer or distributor immediately.

Always read the operating manual before using the device for the first time!

1. First check cable and connector for damages, then plug in the power plug.

2. Insert the annular cutter into the tool holder on the working spindle of the motor and check

the rigid and precise clamping of the tool (>10mm thickness steel sheet).

3. Press the switch MAGNET ON to activate the magnet and ensure holding of the drill stand.

4. Secure the drilling machine by means of a safety chain when machine is working. During

this work we recommend using a coolant spray.

5. Switch the motor on by operating the switch MOTOR ON. Pull over the handle, machine

g oes into full automatic mode. Machine will auto cutting and auto return after complete

cutting. Take special care of sufficient cooling during the drilling process.

6. If not use full automatic drilling mode, don't pull over the handle. Slowly guide the motor

and the rotating cutter to the tool by turning the handle. Take special care of sufficient

cooling during the drilling process.

7. Switch the motor off by pressing the button MOTOR OFF on the control panel.

8. Remove swarf and the remain drill cuttings after the motor has come to a complete

standstill.

9. Operate the switch Magnet OFF to deactivate the magnet.

10. Clean the magnetic surface and remove swarf or any other adhering residues.

OPERATION INSTRUCTIONS

ELECTRICAL SAFETY

SAFETY INSTRUCTIONS

Grounded tools must be plugged into an outlet properly installed and grounded in accordance

with all codes and ordinances. Never remove the ground prong or modify the plug in any way.

Do not use any adapter plugs. Check with a qualified electrician if you are in doubt as whether

the outlet is properly grounded. If the tool should electrically malfunction or breakdown,

grounding provides a low resistance path to carry electrically away from the user.

Warning labels and/or other labels on the machine must be replaced when they were removed.

Do not operate the machine at insufficient lighting conditions.

Do not operate the machine outdoors.

Do not operate the machine when you are tired, when your concentration

is impaired, and/ or under the influence of drugs, medication or alcohol.

Climbing onto the machine is forbidden! Heavy injuries by falling down

or by tilting of the machine are possible.

The machine shall be used only by trained persons.

Non authorized persons, especially children, shall be kept away from

the work area.

Do not wear loose clothing, long hair openly or loose jewellery like

neck-laces etc. when operating the machine

They might be catched by rotating parts and cause serious injuries.

Use proper safety clothing and devices when operating the machine

(, safety goggles, ear protectors, safety shoes …)! Do not wear safety

gloves for oper-ating because they decrease the working accuracy

and they might be pulled into the saw blade.

Before any maintenance you have to disconnect the panel saw from

the power source. Never use the plugged cable for transporting or

manipulating the machine.

People with cardiac pacemakers or other medical appliances may only use this machine

following approval by their physician.

Never touch rotating parts! Keep hands and fingers away from the work area while the

motor is running! Failure to do so can result in severe injuries!