5 6

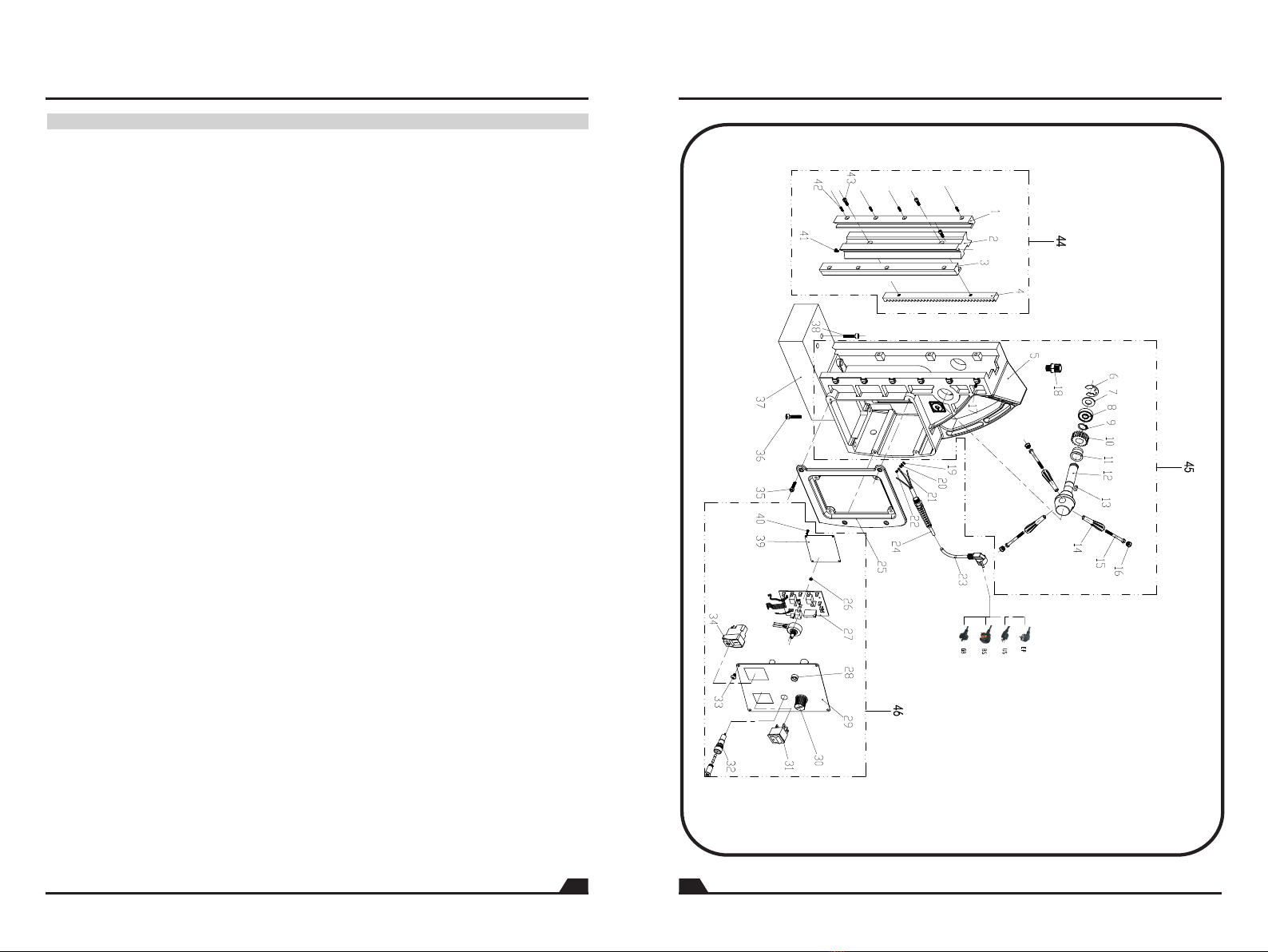

10.The company factory hollow drill are equipped with cooling kettle, please put the kettle

arranged on the corresponding position before operating the machine, and tighten the two

round head screw. The kettle is connected after please figure two (035), fittings is screwed on

the hydrosphere, tighten the end can be on the frame by.

11.After 300 hours of operation, the gear lubricating oil should be replaced.

Consumers buy our machines produced within twelve months, enjoy free maintenance

and warranty service. During normal use of the whole or parts of any manufacturing process

or product failures caused by components, please present the original invoice, the dealer sta-

mped and filled properly warranty certificate to the Company or the Company's designated

repair station to receive free services. machine consumable normal wear and tear, overload,

do not operate according to operating specifications, disassemble, damage caused as a result

of use of parts other than the Company and damage, are not covered by warranty. warranty

expires,provided by the designated repair station maintenance service. maintenance records

must be sealed or signed by the repair station to take effect.

QUALITY ASSURANCE

This tool should be properly grounded, in order to avoid the shock. Grounding device

should have the lead standard, and a grounding plug with earthing special line. Do not be

ground false joint in the line of fire or three-phase line. Grounded power receptacle should

be connected withthe earthing device is connected to the eternal, so that it can work with

yellow green wire connected to the plug hole and connection piece at the same time and

ground connection.

GROUNDING DEVICE

Warning: magnetic drill equipped with a safety rope, when operating, make sure

the magnetic drill and the object is fastened by the rope.In case of power

failure suddenly, causing the machine fall off or thrown objects and

cause accidents.

Attention: Our company does not assume any responsibility because the machine

is not solid or fixed safety facilities are not in appropriate place cause

accident.

FAULT HANDING

FAULTS

Magnetic base

without suction

Machine did not

run after the jump

Magnetic little

suction

Turn the handle gu

ide does not work

Drill out the

elliptical hole

Switch contact undesirable Repair the switch

Repair the power supply

Replace the Fuses

Repair or replace the magnetic bridge

Change the adsorption surface

Power supply is broken

The fuse burn out

Adsorption not on the steel frame

Switch contact undesirable Repair and change switch

Check the electric drill part connector

Repair or replace the electric brush

Changing the armature or stator

Joint loose

Adsorption artifacts thin

Adsorption on the surface is small

Support bar between the adsorption surface

Diode may be virtual welding

Shaft key cut Replace the shaft key

Unscrew the rack bottom screw, remove guide to repair

Wheel and rack misplace

For a drill and a fastener is loose

Bit unilateral cutting

Adsorption surface have sundry Eliminate clutter

Grind anew

Correction of verticality tighten the fasteners

Re Welding

Support bar top tight

Replace the adsorption surface or temporary welding

thick surface adsorption

Replace the adsorption surface or thickening adsorption surface

(>10mm steel sheet)

Brush and commutator poor contact

Drill the armature or stator coil burn out

Electromagnet short circuit or burn out

CAUSES ELIMINATION METHODS

Spindle shake

Electric ignition

Frame adjusting screw loose Tighten adjusting screws

The spark turns orange.

Sparks flying out.

Sparks into a ring of fire

Slow down.

Change the brush, please.

Please check if the motor is burned.