BUILT-IN TEPPAN

INSTALLATION DETAIL

PAGE 2 of 3

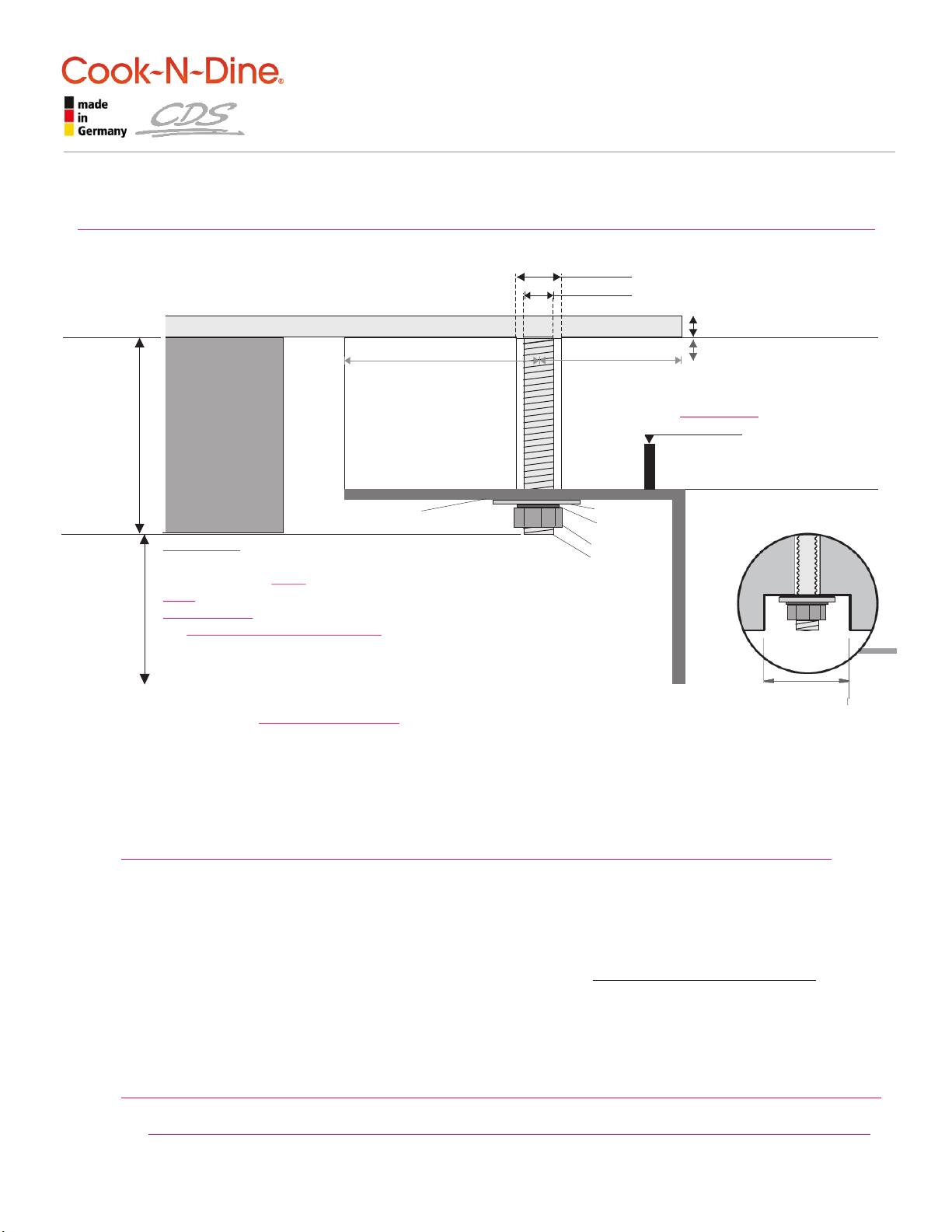

Bolts/studs are 1-3/4 inch (45 mm) long; bolt/stud diameter is 3/16” (5 mm) 8drill 5/16” (8 mm) !!!Ø Ø

VERY IMPORTANT:

DO NOT CUT OR DRILL BEFORE UNIT IS PHYSICALLY PRESENT. DO NOT CUT OFF THE BOLTS/STUDS8 7

8 CAUTION: DO NOT SNAP, PULL or TWIST THE FLEXIBLE CONDUIT DURING INSTALLATION ! ! !

Warranty becomes void if capillary tube inside the conduit (thermostat) is damaged during installation.

CONTROL BOX MUST BE FIRMLY FASTENED TO A NON-MOVING SURFACE.

COUNTER TOP

COUNTER TOP

HEATING

ELEMENT

ENCLOSURE

CUTOUT

TEPPANYAKI COOK TOP COOK-TOP

8 MM | 5/16” REQUIRED HOLE DIAMETER

5 MM | 3/16” BOLT DIAMETER

45 MM

1.8 INCH

STUD

LENGTH

WASHER

LOCK WASHER

NUT

STUD

ANGLE

BRACKETS

PRE-PUNCHED 304

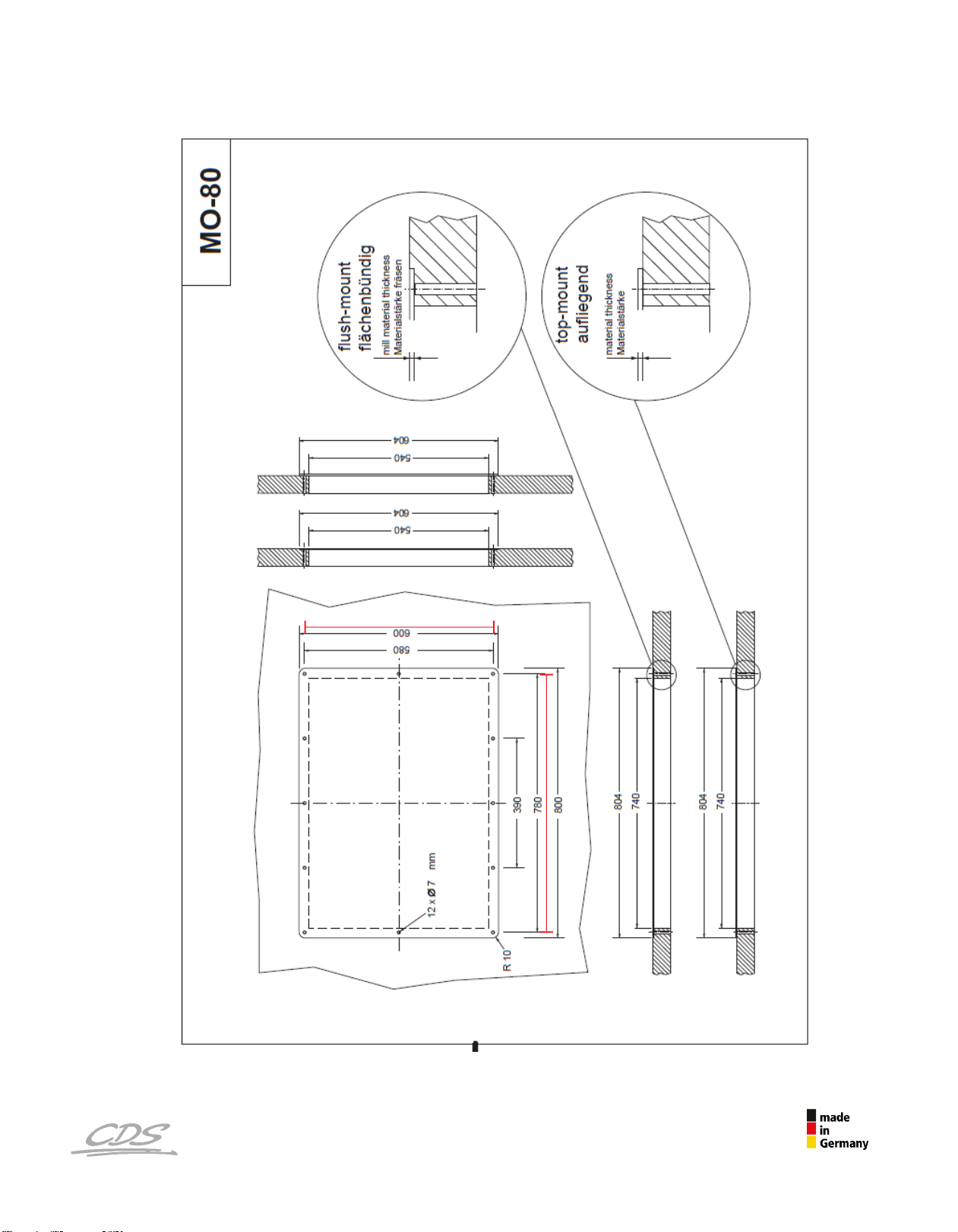

35” x 25/32” x 1-3/16” | 30 x 20 mm

(MO-80 + MO-61 only; order separately)

COUNTER SINK

nuts if necessary

8 7

MO-80: Absolute minimum 6 inches from counter edge to edge of cook top are strongly advised.

! Make sure to HAVE THE UNIT and ALL install sheets ON SITE ahead of time for counter top templating !

ATTENTION !!! MUST READ !!! INSTALLATION INTO STONE/GRANITE COUNTER TOPS

Please be reminded that the CND stainless steel teppanyaki grill surface will flex slightly when switched on thus

developing a shallow dip in the cooking center. This motion is intended and is counteracted by the secured

studs, which hold the unit in place. Talk to your supplier and installer ahead of time. You must provide them

with a full set of install sheet documentation at that time. An experienced stone professional will be able to

advise on all aspects to watch out for, e.g. on how much counter-top (“meat”) is necessary at the narrowest point

for the particular stone of choice to accommodate a Cook-N-Dine built-in teppanyaki appliance properly.

IMPORTANT NOTE: COUNTER TOP THICKNESS OF ~1.5 IN (40 mm) IS MANUFACTURER ADVISED

UNLESS MATERIAL HAS BEEN RE-INFORCED BY MEANS OF RODDING OR COMPARABLE.

RODDING is a professional business practice to strengthen porous, fissured or “brittle” Natural Stone/Granite.

Narrow areas of material are reinforced on the underside

This will support and strengthen those areas and is intended to prevent possible damage.

CND offers 304 stainless steel custom-made 12 gauge pre-punched angle brackets (order separately) which

can be installed along the full length of the cutout (both long sides). The unit is then fastened through the

brackets’ pre-punched holes (see above). Stress applied to the counter material during operation should thus be

evenly distributed. VERY IMPORTANT: The use of brackets cannot guarantee the prevention of damage.

Everything strictly depends on the natural properties of the counter top material. Therefore, Cook-N-Dine can-

not be held responsible for any type of damage to stone counter tops due to installation/operation of CND units.

surrounding large cutouts (e.g. sinks, cook tops)

10 mm

3/8”

20 mm

3/4”

3-4 MM material strength

Optional:

Route metal thickness

for perfect flush installation

IMPORTANT:

WHEN INSERTING THE UNIT,

TIGHTEN THE NUTS WITH A HAND WRENCH.

DO NOT USE FORCE!!! NO POWER TOOLS!!!

THE STUDS MUST SLIDE

INTO THEIR DESIGNATED

HOLES EASILY AND

! ! ! WITHOUT ANY RESISTENCE ! ! !

RE-TIGHTEN AFTER A COUPLE OF USES. NOTE: DRAWINGS ARE NOT TO SCALE.

©2016 p&p | www.cookndine.com | All rights, errors and misprints reserved.

RODDING:

inserted epoxied metal rod

to re-inforce stone counter

(ref. OFFICIAL MARBLE

INSTITUTE OF AMERICA INFO)

4 inch | 10 cm

CLEARANCE