CE-2500-HVE Band Sealer

Page 1

Contents

I. Use ...............................................................................................................................................2

II. Safety Precautions.......................................................................................................................................2

III. Main Specification.......................................................................................................................................3

IV. Performance Features .................................................................................................................................4

V. Structure & Working Principle .....................................................................................................................5

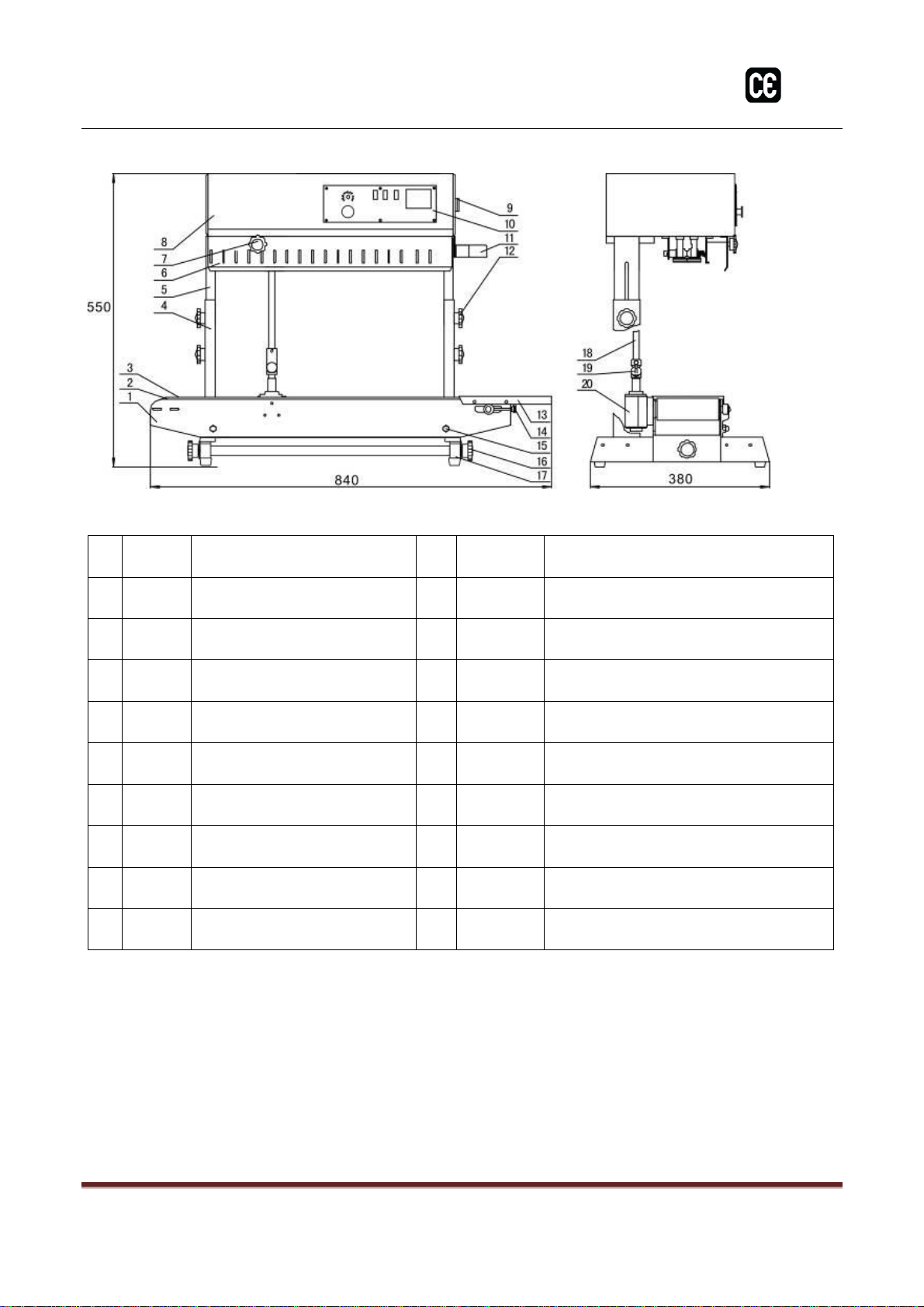

Diagram 5.1............................................................................................................................6

Diagram 5.2............................................................................................................................7

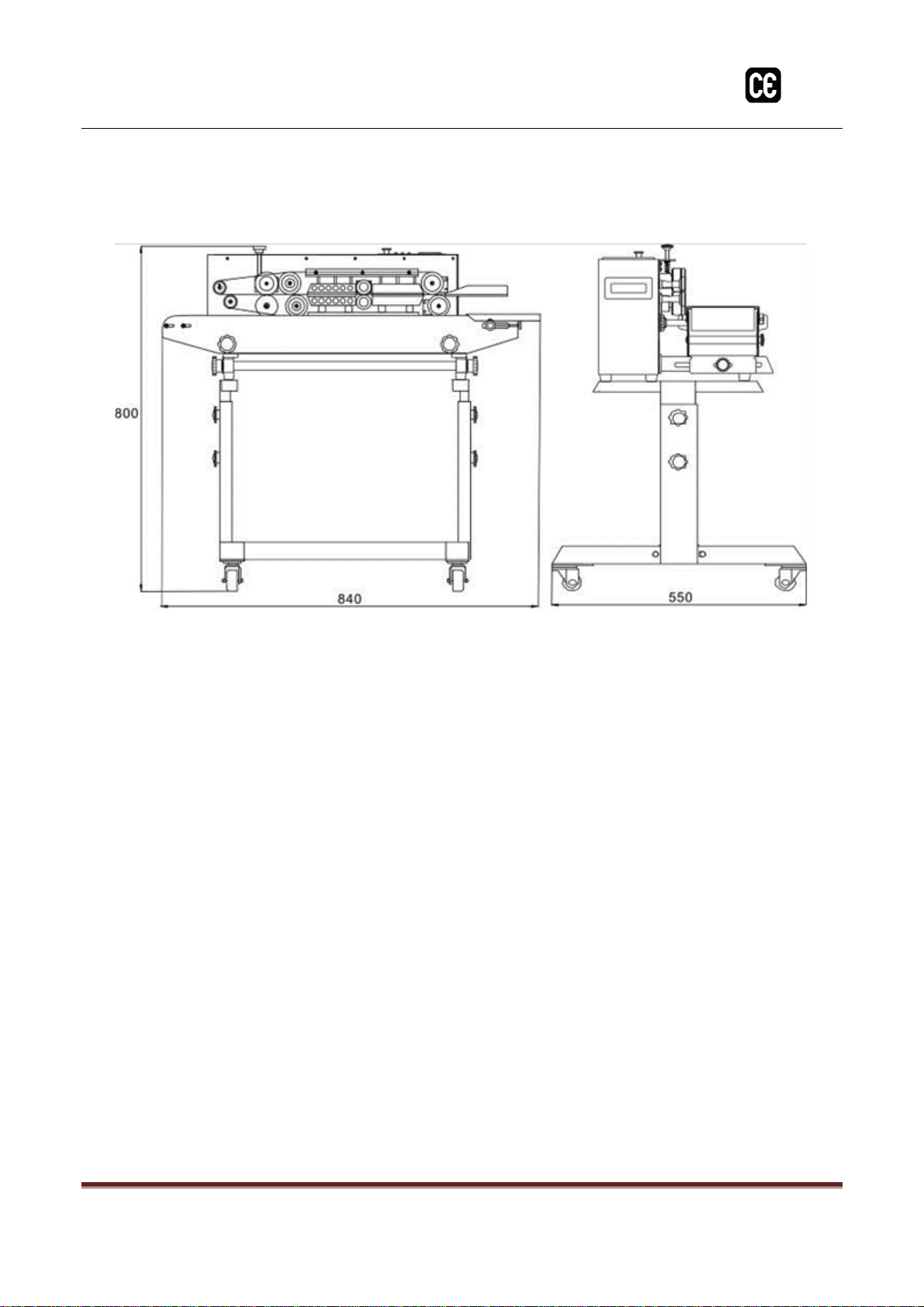

Diagram 5.3............................................................................................................................8

VI. Operational Use...........................................................................................................................................9

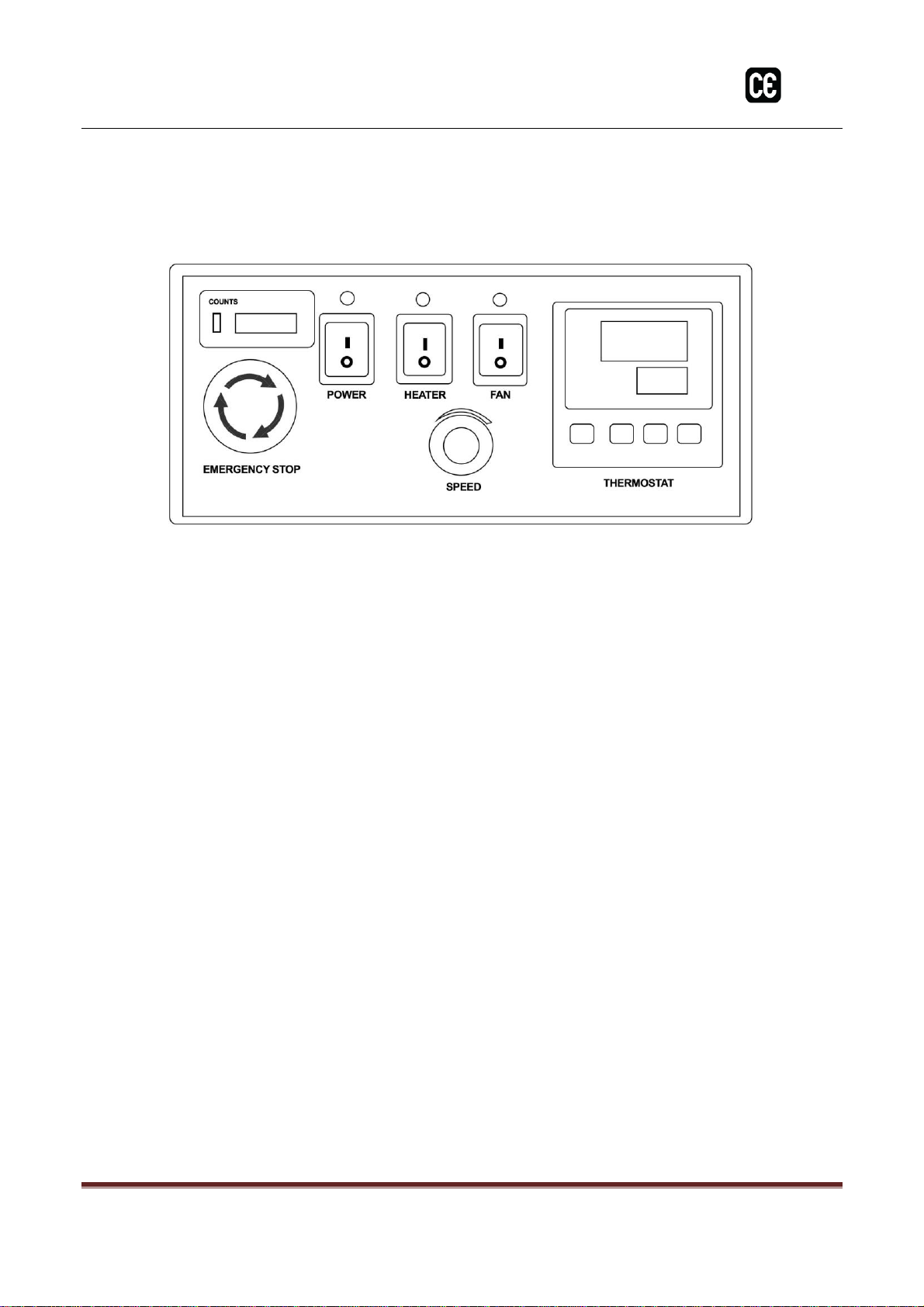

6.1. Control Panel ................................................................................................................................9

Diagram 6.1............................................................................................................................9

6.2. Prepare the machine for use ..........................................................................................................9

6.3. Sealing Belt Adjustment / Replacement .......................................................................................10

Diagram 6.2..........................................................................................................................10

6.4. Drive Wheel Block Adjustment.....................................................................................................11

Diagram 6.3..........................................................................................................................11

6.5. Conveyor Belt Adjustment / Replacement....................................................................................12

Diagram 6.4..........................................................................................................................12

6.6. Starting procedure .......................................................................................................................13

VII. CE-2500-HVE Horizontal to Vertical Guide .................................................................................................14

VIII. Stand Assembly .........................................................................................................................................17

IX. Electrical Diagram......................................................................................................................................20

Diagram 9.1..........................................................................................................................20

X. Sealing Unit Parts List ................................................................................................................................21

Diagram 10.1........................................................................................................................21

XI. Conveyer Parts List ....................................................................................................................................23

Diagram 11.1........................................................................................................................23

XII. Component Parts List.................................................................................................................................25

Diagram 12.1........................................................................................................................25

XIII. Conveyor Table Parts List ...........................................................................................................................27

Diagram 13.1........................................................................................................................27

XIV. CE-2500-HVE Parts Kit................................................................................................................................29

XV. Preventive Maintenance Checklist.............................................................................................................30

XVI. Troubleshooting.........................................................................................................................................31

XVII. Helpful Links .............................................................................................................................................32