1. INTENDED USE

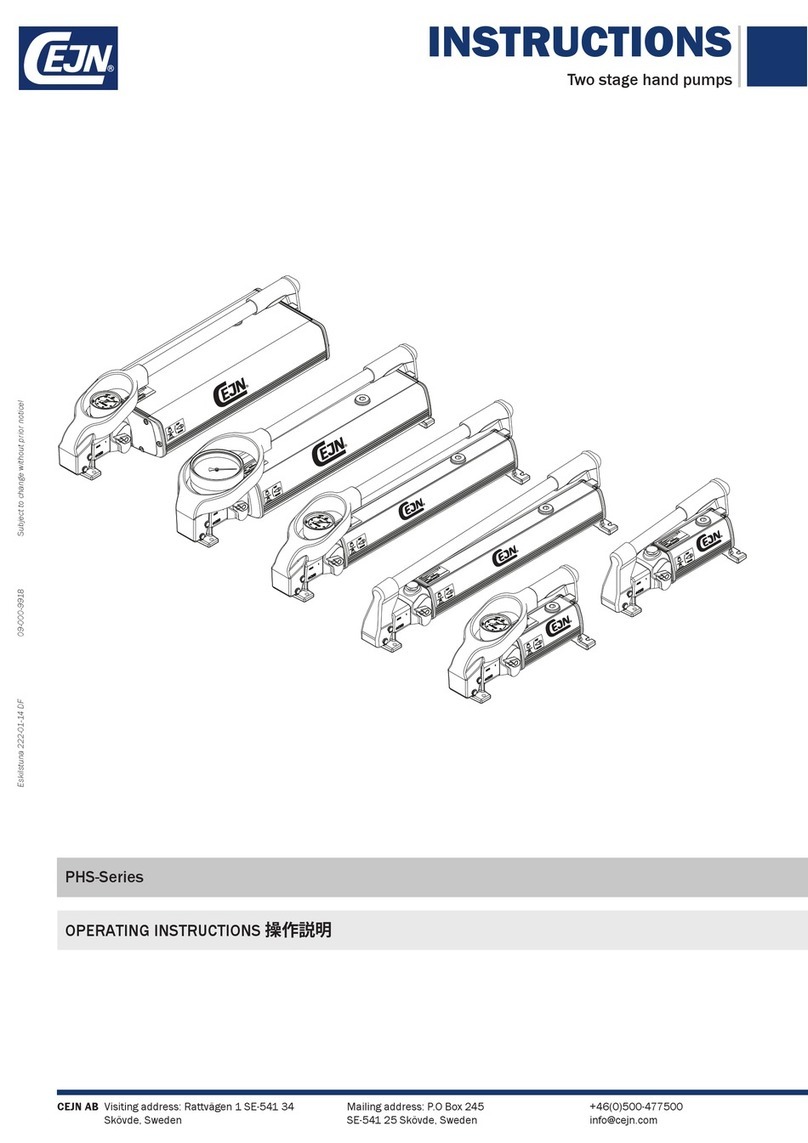

Basic configuration of pump, cylinder and hydraulic control.

- Some examples of possible system configurations using CEJN hydraulic products.

- System configuration such as production process, facility maintenance process and press lifting is

possible.

- CEJN hydraulic system could be designed in various system ways a according to work and be

applied to any applications.

- We will provide you the best products possible.

Hand pump system

- The most basic system configuration is a cylinder drive system using a hand pump.

1) Cylinder (single acting / double acting type can be used): Mechanical actuator using power from

hydraulic fluid.

2) Hand pump: Device for converting fluid energy into mechanical energy.

3) Gauge Block : Parts for combining gauge and pump.

4) Manual Valve : Valve for controlling double acting cylinder.

5) Hose: To transfer fluid

6),7) Coupler : Connector hose with cylinder.

8) Gauge : Measurement for force and pressure.