8

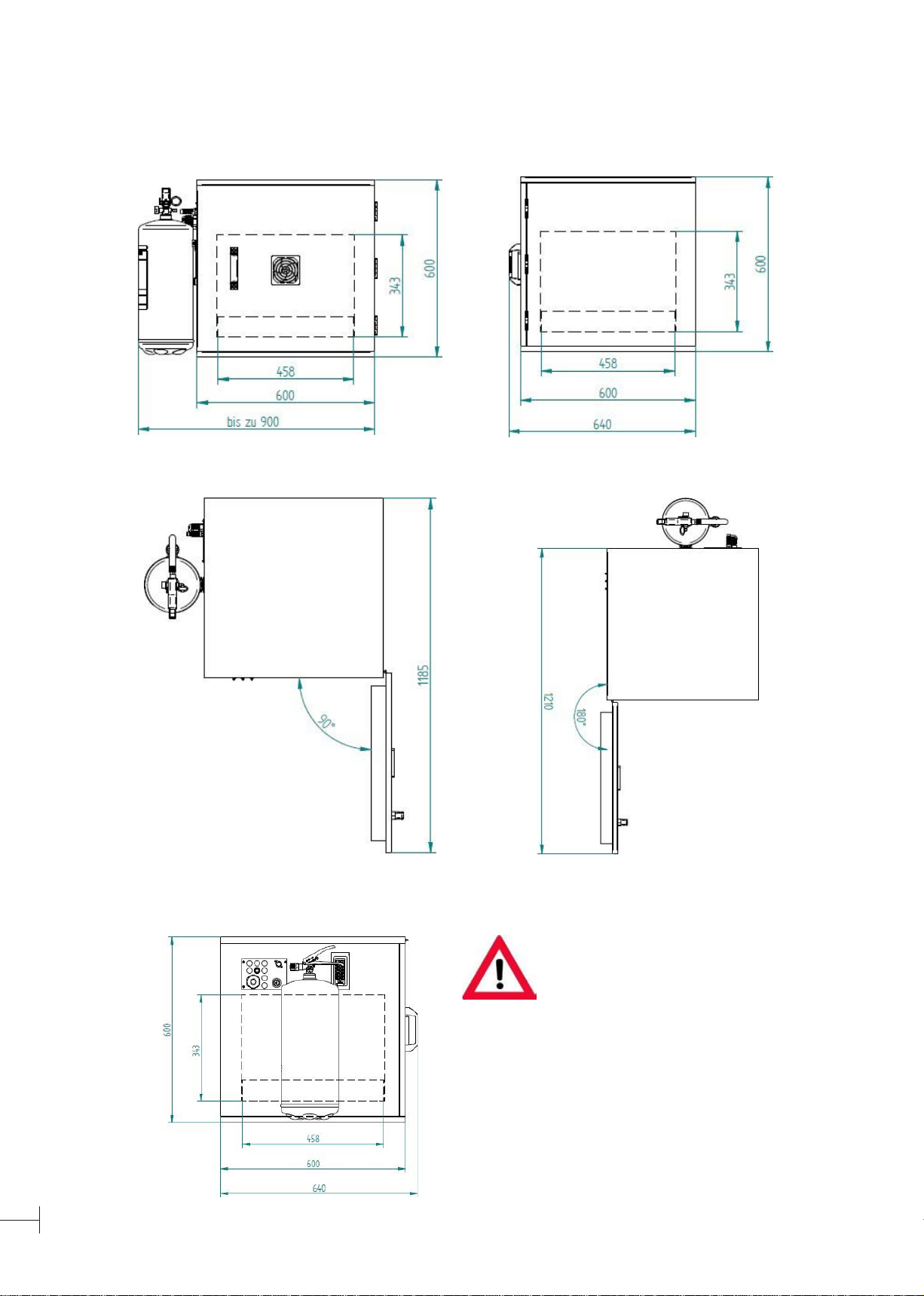

• The door of the QUBE®safety case may be opened up to a maximum of 180°.

• For the best possible protection, the batteries that are to be stored / charged must be

placed as at as possible in the bottom pan.

• Protect the QUBE®safety case from splashing water with increased pressure or permanent

uid exposure. Fluid exposure with regard to the power plug and the socket strip is to be

completely avoided!

• Do not expose to direct UV or sunlight. Do not operate heaters in the immediate vicinity.

• Do not operate the QUBE® safety case in an environment where ammable gases, vapors

or dust exist.

• Protect the QUBE® safety case from strong vibrations and other mechanical inuences, as

it can be damaged by the eects.

• Keep the QUBE®safety case away from children. This is not a toy!

• For installation, operation and maintenance, the applicable occupational safety, accident

prevention, DIN/VDE regulations must be observed on their own responsibility.

• Obviously damaged lithium batteries should not be stored inside buildings.

• The operating and instruction manual of the QUBE®safety case must be constantly availa-

ble at the place of use.

• Do not store any highly inammable materials / re loads in the immediate vicinity of the

QUBE®safety case

• Do not operate the QUBE®safety case in poorly ventilated rooms (especially not inside

poorly ventilated living spaces)

• The maximum energy (in Wh) of the stored batteries must be observed (see 2.1 technical

specications)

4. Transport, Installation & Commissioning

4.1 General information

The QUBE® safety case must be checked immediately upon delivery and any recognisable defects must

be immediately noted on the accompanying document / consignment note from the freight forwarder. De-

fects have to be reported to the seller or the Celsion Brandschutzsysteme GmbH in writing (no later than

5 working days after delivery).

The transfer of risk is upon delivery. Defects that may have arisen as a result of further transport of the

systems are excluded from subsequent performance.

In case of doubt, the device is not to be used!

Please note that a switch (e.g. circuit breaker or power switch) must be assigned to this device as a dis-

connection device. This applies both to an integration into the electrical installation of the building, as

well as to the connection with the standard power plug.

Care should be taken to ensure that this switch is properly installed and easily accessible to the user.

Any specications regarding the electrical protection of the regulations applicable on site must be taken

into account.

The safety case must not be operated with the aid of a socket strip.

Improper installation can damage both the product and all other connected devices.

4.2 Transport

Improper transport (hard impacts, transport without air suspension, repeated reloading, unilateral loading

during installation, etc.) can have an impact on the re protection function (damage to the re protection

panels or their connections).

If a relocation of the system is necessary, it may only take place uniformly, over the entire surface and

with the door closed.

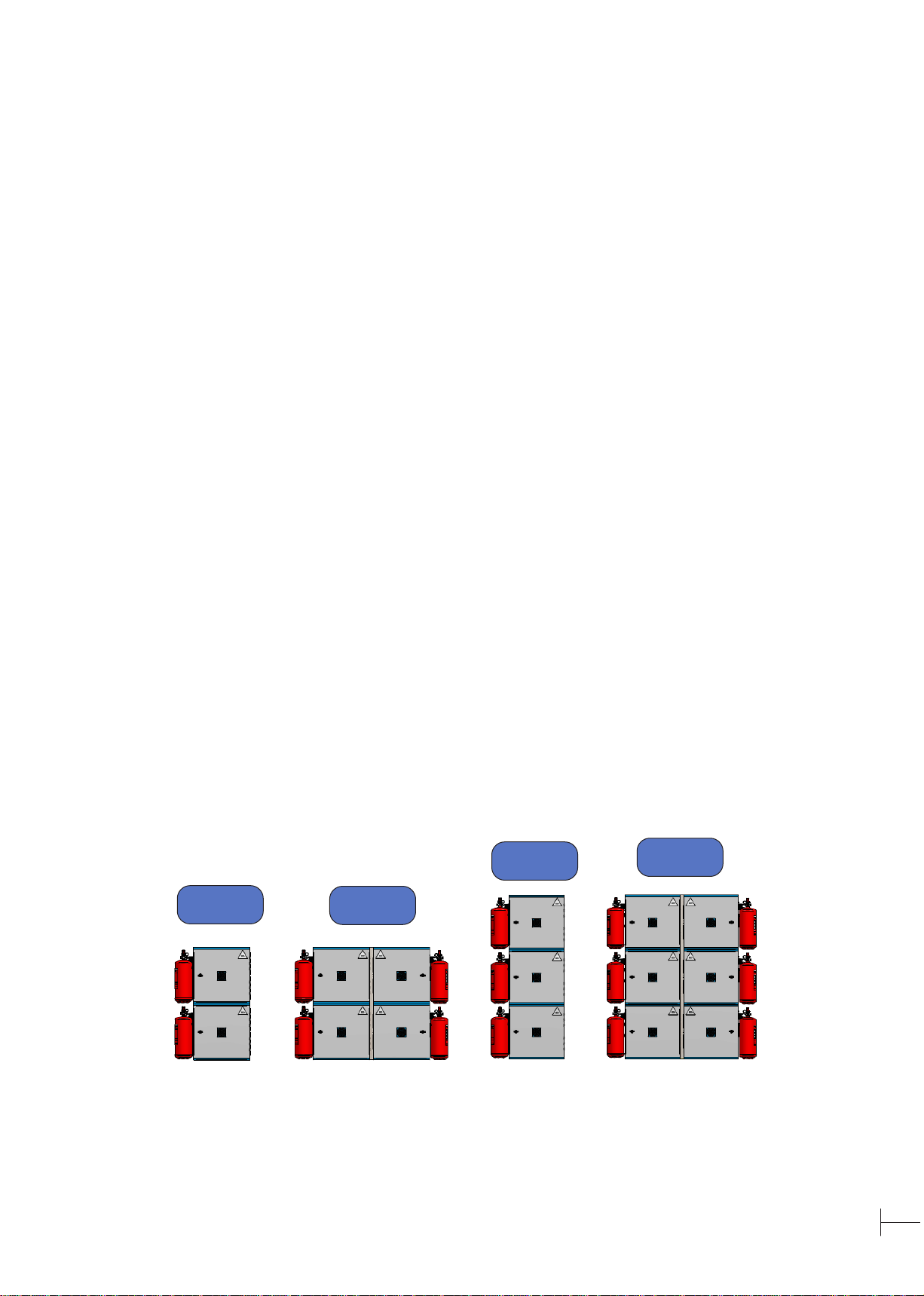

For safety and approval reasons (CE), the safety case may only be transported

or moved separately from the extinguishing medium tank. Transport with an

attached extinguishing medium tank is not permitted!