CEM DT-5302 User manual

DIGITAL LOW RESISTANCE TESTER

INSTRUCTION MANUAL

Low Resist anc e Tester

400m

4

40

V

A

A

4

(2)

1

(3)

(1) (2)

(1) (1)

(2)

1

2

I. SAFETY INFORMATION

1. NEVER apply voltage or current to the meter that exceeds the

specified maximum:

2. USE EXTREME CAUTION when working with high voltages.

3. DO NOT measure voltage if the voltage on the "COM" input

jack exceeds 1000V above earth ground.

4. NEVER connect the meter leads across a voltage source while

the function switch is in the current, resistance, or diode mode.

Doing so can damage the meter.

5. ALWAYS discharge filter capacitors in power supplies and

disconnect the power when making resistance or diode tests.

6. ALWAYS turn off the power and disconnect the test leads

before opening the covers to replace the fuse or batteries.

7. NEVER operate the meter unless the back cover and the

battery and fuse covers are in place and fastened securely.

8. If the equipment is used in a manner not specified by the

manufacturer, the protection provided by the equipment may

be impaired.

3

Safety symbols:

Caution refer to this manual before using the meter.

Dangerous voltages.

Meter is protected throughout by double insulation or

reinforced insulation.

When servicing, use only specified replacement parts.

CE Comply with EN-61010-1

II

.

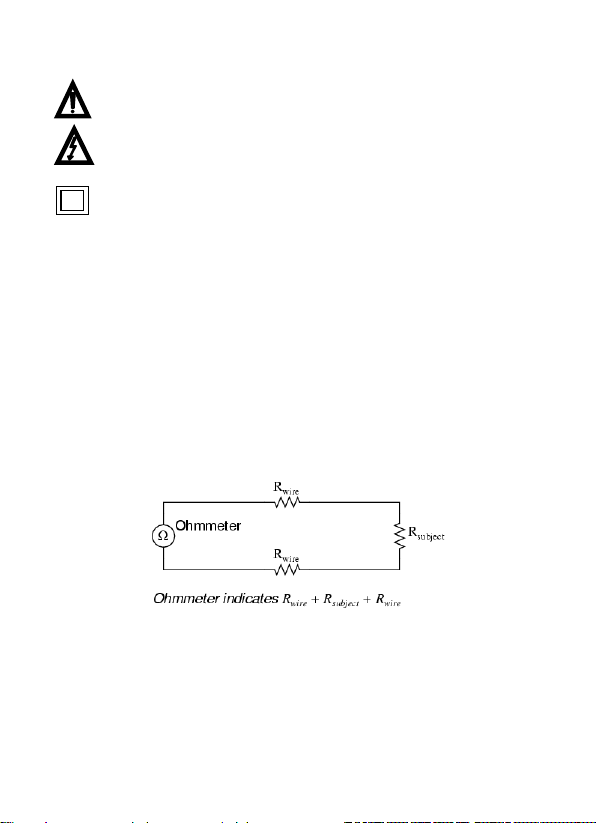

OPERATING PRINCIPLE

Suppose we wished to measure the resistance of some component

located a significant distance away from our ohmmeter. Such a

scenario would be problematic, because an ohmmeter measures all

resistance in the circuit loop, which includes the resistance of the

wires (Rwire) connecting the ohmmeter to the component being

measured (Rsubject):

Usually, wire resistance is very small (only a few ohms per hundreds

of feet, depending primarily on the gauge (size) of the wire), but if

the connecting wires are very long, and/or the component to be

measured has a very low resistance anyway, the measurement error

introduced by wire resistance will be substantial.

4

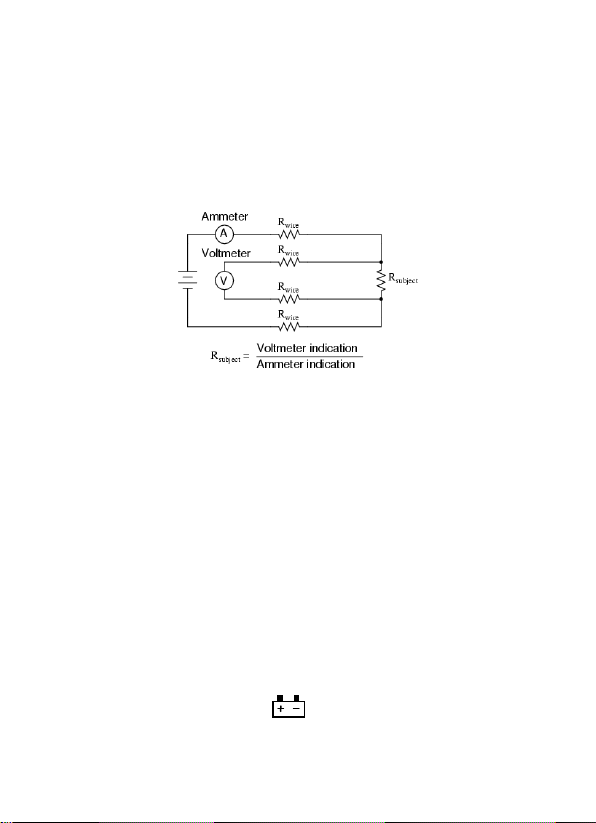

An ingenious method of measuring the subject resistance in a

situation like this involves the use of both an ammeter and a

voltmeter. We know from Ohm's Law that resistance is equal to

voltage divided by current (R = E/I). Thus, we should be able to

determine the resistance of the subject component if we measure

the current going through it and the voltage dropped across it:

Current is the same at all points in the circuit, because it is a series

loop. Because we're only measuring voltage dropped across the

subject resistance (and not the wires' resistances), though, the

calculated resistance is indicative of the subject

component's resistance (Rsubject ) alone.

III. FEATURES

Low resistance range: 0~40Ω

Display: Large LCD with bar graph display

Maximum output current : 200mA (400mΩ)

Sampling Rate: 2 times per second.

relative measurement

Over Range Indicator: OL of highest digit is displayed.

Low Battery Indication: The is displayed when the

battery Voltage drop below the operating voltage.

5

Auto Power Off

To conserve battery life, the meter will automatically turn off after

approx. 30 minutes of non-use. When this happens, the state of the

meter is saved. In order to disable auto power off function, power on

the meter when any of the push function , except for HOLD, is

pressed down.The “APO” sign on the LCD panel indicates whether

the auto power-off function is enabled or not.

Operating Temperature: 0ºC to 40ºC (32ºF to 104ºF)

and Humidity below 80% RH

Storage Temperature: -10ºC to 60ºC (14ºF to 140ºF)

and Humidity below 70% RH

Power source: 6x1.5V Size “AA” battery or Equivalent (DC9V)

Dimensions: 200(L) x 92(W) x 50(H) mm

Weight: Approx 700g include battery

Accessories: 4 sets Te st kits, 4pcs iron rods, 6pcs battery, Carrying

case, manual.

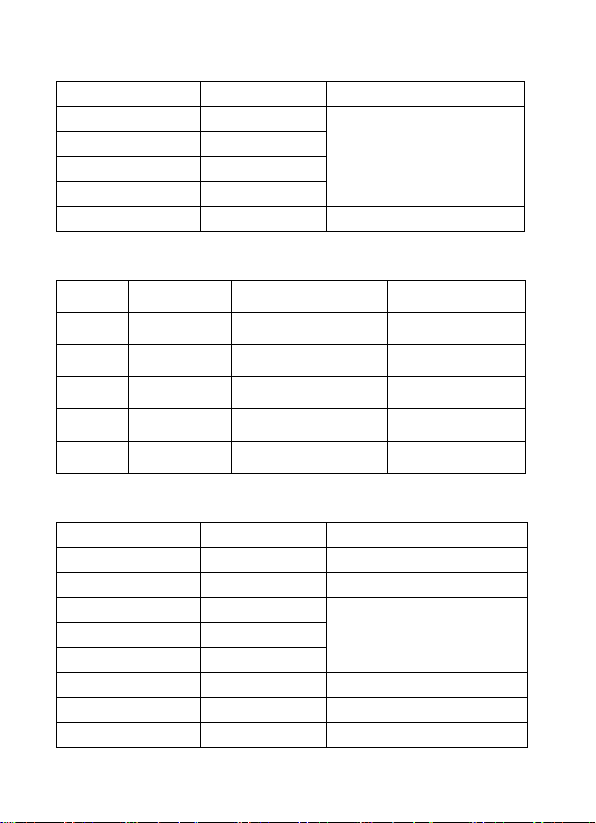

IV. Electrical Specifications

Accuracies are specified in the way:

± (…% of reading +…digits) at 23ºC ± 5ºC,below 80% RH.

Low resistance

Range

Resolution

Accuracy

Current

400mΩ

0.1mΩ

± (1%+10d)

200mA

4Ω

1mΩ

± (1%+5d)

20mA

40Ω

0.01Ω

± (1%+5d)

2mA

6

OHMS

Range

Resolution

Accuracy

400Ω

0.1Ω

± (1.0% + 4d)

4KΩ

1Ω

± (1.5% + 2d)

40KΩ

10Ω

400KΩ

100Ω

4MΩ

1K

± (2.5% + 3d)

40MΩ

10kΩ

± (3.5% + 5d)

DC Current

Rang

Resolution

Accuracy

400µA

0.1µA

± (1.5%+5d)

4000µA

1µA

40mA

0.01mA

400mA 0.1mA

AC Current

Rang

Resolution

Accuracy/50~60Hz

Accuracy/400Hz

400µA

0.1µA

± (1.5%+5d)

± (1.5%+5d)

4000µA

1µA

± (1.5%+5d)

± (1.5%+5d)

40mA

0.01mA

± (1.5%+5d)

± (1.5%+5d)

400mA

0.1mA

± (1.5%+5d)

± (1.5%+5d)

7

DC Voltage

Rang

Resolution

Accuracy

400mV

0.1 mV

± (1%+5d)

4V

1 mV

40V

0.01V

400V

0.1V

1000V

1V

± (1.2%+5d)

AC Voltage

Rang Resolution Accuracy/50~60Hz Accuracy/400Hz

400mV 0.1 mV ± (1.2%+10d) ± (2.5%+10d)

4V 1 mV ± (1.0%+10d) ± (1.2%+10d)

40V 0.01V ± (1.0%+10d) ± (1.2%+10d)

400V 0.1V ± (1.0%+10d) ± (1.2%+10d)

750V 1V ± (1.0%+10d) ± (1.2%+10d)

Capacitance

Rang

Resolution

Accuracy

4nF

1pF

unspecified

40nF

10PF

± (5.0% + 20d)

400nF

0.1nF

± (3%+10d)

4uF

1nF

40uF

10nF

400uF

0.1uF

± (4%+10d)

4mF

1uF

± (10%+10d)

40mF

10uF

unspecified

8

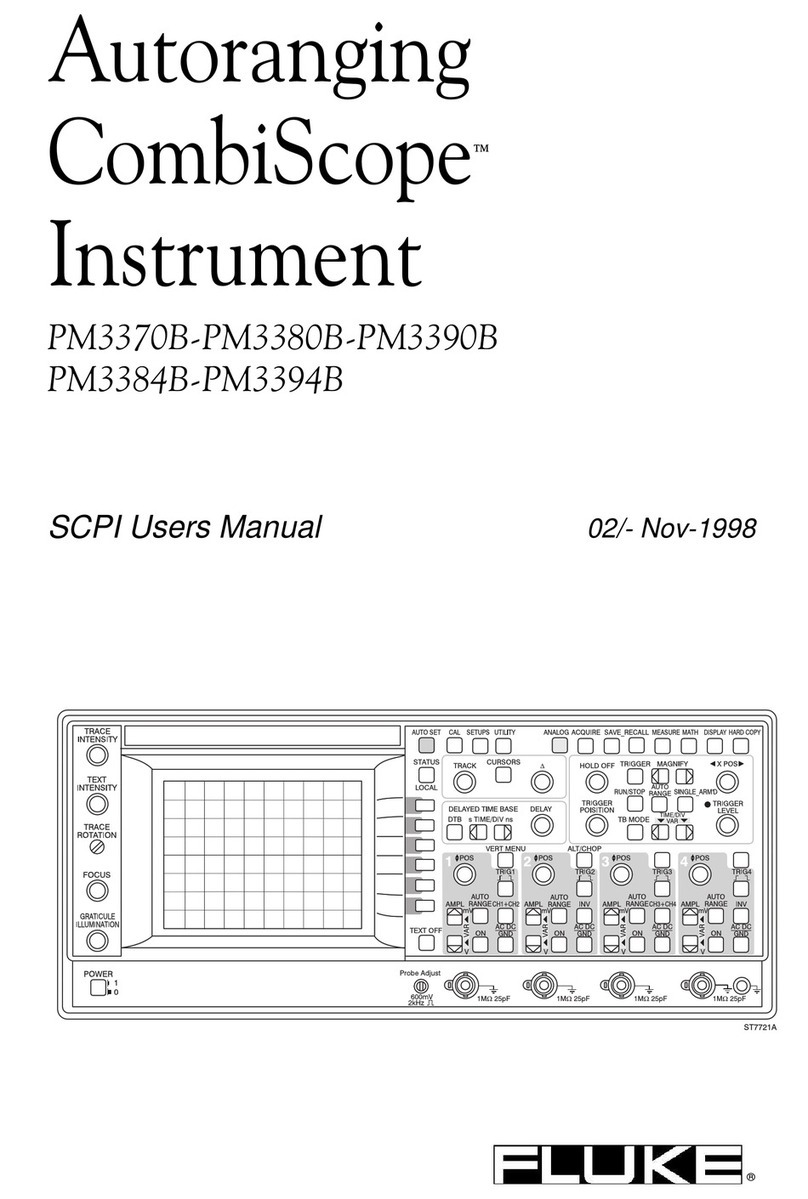

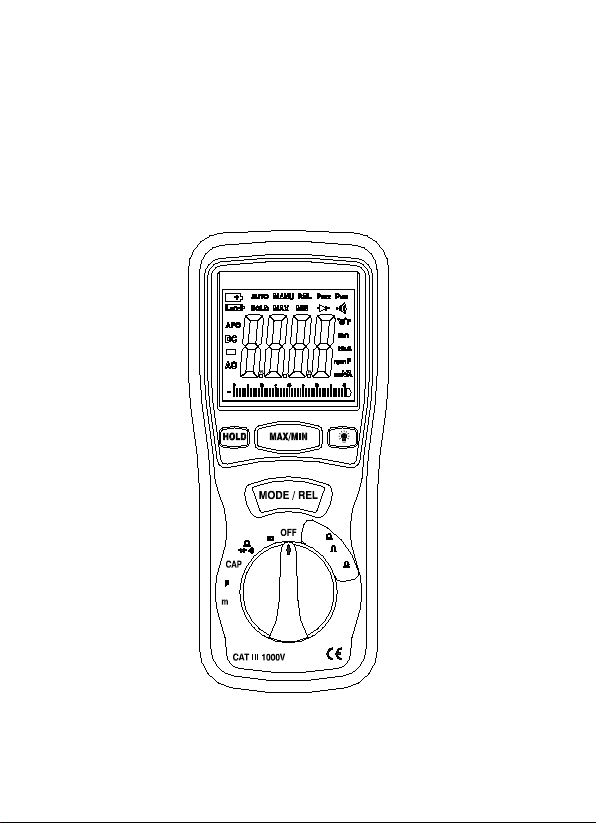

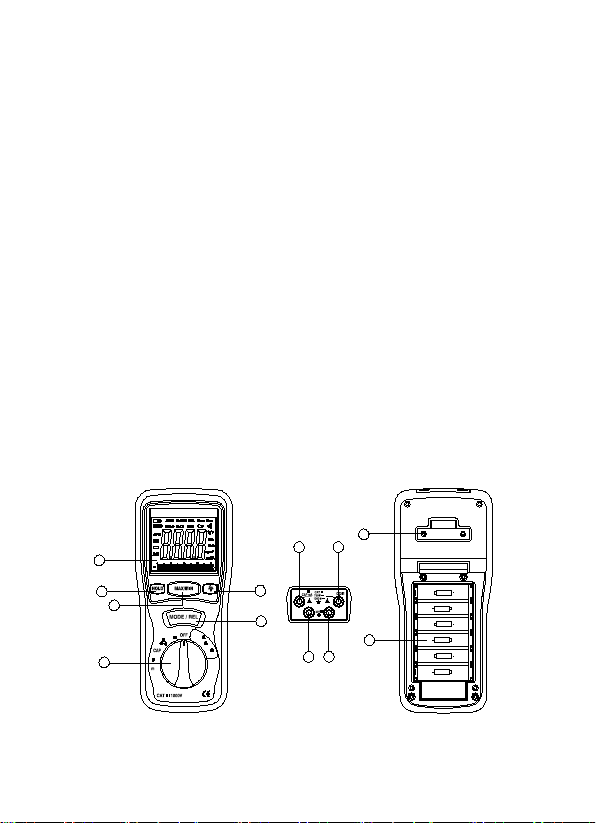

V. PARTS & CONTROLS

①Digital Display

②Data Hold Button

③MAX/MIN Button

④Backlight Button

⑤Mode/REL Button

⑥Rotary Function switch

⑦V Ω Cap mA E2 Jack

⑧COM E1 jack

⑨P2 Jack

⑩P1 jack

⑪PothooK

⑫Battery Cover

Low Resista nce Tester

E

P

E

P

12

2 1

V

400m

4

40

V

A

A

AA

+

+

AA

+

AA

AA

+

+

AA

+

AA

4

(2)

1

(3)

(1)(2)

(1) (1)

(2)

1

2

3

5

7

4

8

12

69

10

11

9

Button Function Operation

HOLD button

The HOLD function allows the meter to "freeze" a measurement for

later reference.

1. Press the HOLD button to “freeze” the reading on the indicator.

The “HOLD” message will be appear in the display.

2. Press the HOLD button again to return to normal operation.

MAX/MIN button

The MAX/MIN function allows the meter to capture the highest or

lowest measurement for later reference.

1 Press the MAX/MIN button to begin measurement. The indicator

“MAX” or “MIN” will appear in the display.

2. If the “MAX MIN” messages are flashing, the instrument is in

MAX/MIN mode but not recording, press the MAX/MIN button to

select a mode.

3. To return to normal AUTO measurement mode, hold down the

MAX/MIN button for 2 seconds.

Backlight

Press the key for to turn on the display backlight function.

The backlight will automatically turn off after 15 seconds.

MODE/REL button

To select AC or DC measurement when in Voltages, mA , uA ,Ω,

, •))) . RELATIVE ZERO BUTTON:

For convenient readings comparison & offset when in low resistance

test .

10

DC/AC VOLTAGE MEASUREMENT

1. Sert the black test lead into the negative COM jack and the red

test lead into the V Ω Cap mA E2 Jack

2. Set the function switch to the V position.

3. Use the MODE button to select AC or DC Voltage

4. Connect the test leads in parallel to the circuit under test.

5. Read the voltage measurement on the LCD display

DC/AC CURRENT MEASUREMENT

1. Insert the black test lead banana plug into the negative (COM)

jack.

2. For current measurements up to 4000uA, set the function switch

to the uA position.

3. For current measurements up to 400mA, set the function switch

to the mA range.

4. Press the ‘MODE/REL’ button until “DC” or “AC” appears in the

display.

5. Remove power from the circuit under test, then open up the

circuit at the point where you wish to measure current.

6. Touch the black test probe tip to the negative side of the circuit.

Touch the red test probe tip to the positive side of the circuit.

7. Apply power to the circuit.

8. Read the current in the display. The display will indicate the

proper decimal point, value and symbol.

11

RESISTANCE [ Ω ] MEASUREMENT

WARNING: To avoid electric shock, disconnect power to the

unit under test and discharge all capacitors before taking any

resistance measurements. Remove the batteries and unplug the

line cords.

1. Set the function switch to the Ωposition.

2. Insert the black test lead plug into the negative (COM) socket

and the red test lead plug into the positive Ω jack.

3. Press the MODE button until “Ω” appears in the display.

4. Touch the test probe tips across the circuit or part under test. It is

best to disconnect one side of the part under test so the rest of

the circuit will not interfere with the resistance reading.

5. Read the resistance in the display. The display will indicate the

proper decimal point, value and symbol.

CONTINUITY CHECK

WARNING: To avoid electric shock, never measure continuity

on circuits or wires that have voltage on them.

1. Set the range switch to the •))) position.

2. Insert the black lead plug into the COM socket and the red

test lead plug into the positive •))) socket.

3. Press the MODE button until “•)))” appears in the displa

4. Touch the test probe tips to the circuit or wire you wish to

check.

5. If the resistance is less than 35Ω, the audible signal will sound.

The display will also show the actual resistance in ohms.

12

DIODE TEST

WARNING: To avoid electric shock, do not test any diode that

has voltage on it.

1. Set the function switch to the position.

2. Insert the black test lead plug into the COM socket and the red

test lead plug into the socket.

3. Press the MODE button until “ ” appears in the display.

4. Touch the test probe tips to the diode or semiconductor junction

you wish to test. Note the meter reading.

5. Reverse the probe polarity by switching probe position. Note

this reading.

6. The diode or junction can be evaluated as follows:

A. If one reading shows a value and the other reading shows

OL, the diode is good.

B. If both readings show OL, the device is open.

C. If both readings are very small or zero, the device is shorted.

NOTE: The value indicated in the display during the diode check is

the forward voltage.

CAPACITANCE MEASUREMENT

WARNING: To avoid electric shock, discharge the capacitor under

test before measuring.

1 Set the function switch to the CAP capacitance position.

2 Insert the black test lead banana plug into the negative COM

jack and the red test lead banana plug into the CAP positive

jack.

13

3 Touch the test probe tips across the part under test.

4 Read the capacitance value in the display.

5 The display will indicate the proper decimal point and value.

Note: For very large values of capacitance measurement time can

be several minutes before the final reading stabilizes. The LCD

displays DSC when discharging. Discharging through the chip is

quite slow. We recommend the user to discharge the capacitor with

some other apparatus.

Low resistance measurement

WARNING: To avoid electric shock, disconnect power to the

unit under test and discharge all capacitors before taking any

resistance measurements.

1. Insert the red test leads banana plug into E2,P2 red com

jack,and black test leads banana plug into E1,P1 black com

jack.

2. At the range of 40 Ω, connect the clips to the low resistance’s

terminals, If the reading is too low then switch the range to 4 Ω

or 400m Ω.

3. Remove the clips from the low resistance terminals, and connect

then each other ,then press “ MODE/REL” button.

4 . Connect the clips to the low resistance’s terminal again.

5 . Read the resistance in the display. The display will indicate the

proper decimal point, value and symbol.

14

VI. Battery Replacement

1. When the low battery symbol appears on the LCD,

the six 1.5V ‘AA’ batteries must be replaced.

2. Turn the meter off and remove the test leads.

3. Unsnap the tilt stand from the rear of the meter.

4. Remove the four Phillips head screws

holding the battery cover.

5. Remove the battery compartment cover

6. Replace the batteries observing

Polarity.

7. Affix the rear cover and secure the

screws.

8. Reattach the tilt stand.

15

V06/08

Table of contents

Other CEM Test Equipment manuals