OPERATINGTHESAW

Werecommendthateyeproteconbeworn,andnormalsafe

workingpraccesobservedaspertheHealthandSafetyatwork

act,andtheappropriateNaonalandStateLaws.

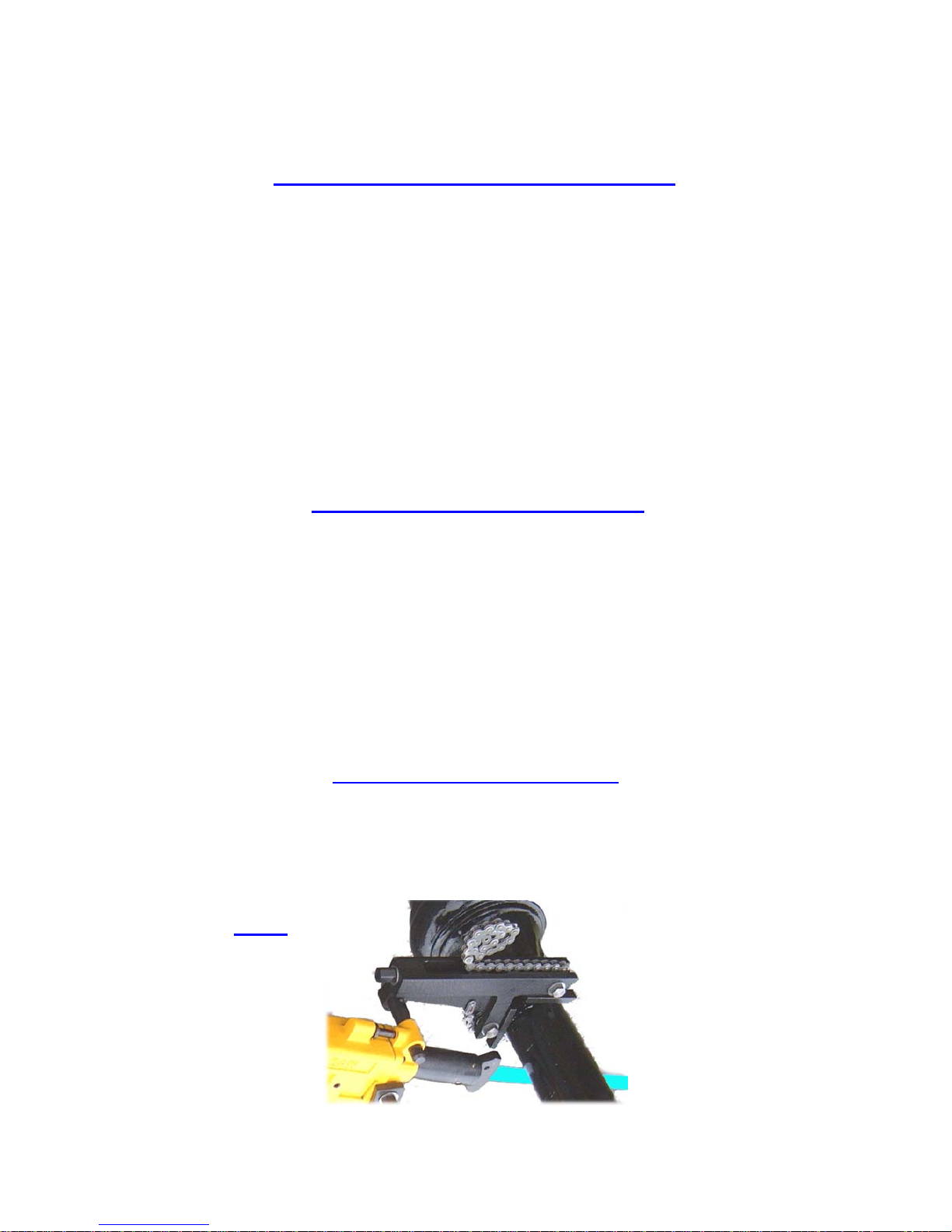

TheJSZshouldbeusedinconjunconwiththepipeclampwhere

possible.

Connecttheairsupply,restthebladeonthematerialtobecut

withthenosepiecefirmlyabuedtotheworkpiece,withforward

handpressure,topreventjudder.AllowtheCengarSawtocut

underitsownweight,withjustaslightdownwardhandpressure

tokeeptheteethengagedinthecut.Itisnotnecessarytoput

excessivedownwardpressureonthesaw,thisonlyaccelerates

bladewear,andpreventsthesawfromoperangefficiently.

Normalairlinepressureof5to6Barisrequired,anyhigher

pressureonlyacceleratesinternalwearofthemachine.

USEINHAZARDOUSAREAS

Westronglyadvisethatthecontactareaofthebladeonthework

piecebequenchedwithcoolantorwaterduringcungto

dissipateanyheatwhichmaybecreatedbythecungprocess.

An‐stacconducveairhosemustbeused,withadequate

earthbondconnuity(resistancebelow1ohm),togroundany

electrostaccharges.

MAINTENANCEANDGENERALHINTS

Alwaysensuresufficientoilinthetool,especiallywhenthesawis

inconstantuse.

Thevalveunitpartno.8308isavitalcomponentmanufacturedto

closetolerances,andwillnottolerateabusivetreatment.

Lubricaonisessenal.Anyneglectwillseriouslyaffect

performanceofthesaw,causingthesawtostallintermiently,or

stopcompletely.

Verylilemaintenanceisrequiredifthecorrectoilisused,but