CenterLine VeriFast MicroView 1.0 User manual

connecting needs with capabilities

VeriFastTM MicroView 1.0 User Manual

MicroView 5-port Dual Device

MicroView 10-port Dual Device

MicroView 5-port Single Device

Ver. 1.9 – December 2018

FDP-VFA-MCV-UM-EL-1.9-1218

Product Sales and Support

The VeriFast™ MicroView is a component of a resistance welding system manufactured by:

For all replacement parts and service inquiries, contact CenterLine’s inside sales department:

Telephone: 519.734.8330

Toll Free in Canada & US: 1.800.268.8330

Fax: 519.734.2006

Email: info@cntrline.com

Visit www.cntrline.com for detailed information on any of the facilities listed below.

Manufacturing Facilities

Regional Sales/Service

Offices

Machinery Division

415 Morton Drive

Windsor ON N9J 3T8

Canada

CAN. 519.734.8464

U.S. 313.962.1448

Toll Free: 1.800.820.6977

Email: info@cntrline.com

Mechatronics Division

6290 Morton Industrial Pkwy

Windsor ON N9J 3W3

Canada

CAN. 519.734.8464

U.S. 313.962.1448

Toll Free: 1.800.820.6977

Email: info@cntrline.com

CenterLine Welding Products

1985 Ring Drive

Troy MI 48083

USA

U.S. 877.574.5400

Automation Components Division

655 Morton Drive

Windsor ON N9J 3T9

Canada

CAN. 519.734.8330

U.S. 313.961.3731

Toll Free: 1.800.268.8330

Email: info@cntrline.com

Electrodes Division

595 Morton Drive

Windsor ON N9J 3T8

Canada

CAN. 519.734.6886

U.S. 313.961.4080

Toll Free: 1.800.249.6886

Email: info@cntrline.com

CenterLine SE USA

3409 Lorna Lane

Hoover, AL 35216

USA

U.S. 205.310.9103

Email: Stuart.Rogers@cntrline.com

Supersonic Spray Technologies

Div.

655 Morton Drive

Windsor ON N9J 3T9

Canada

CAN. 519.734.8464

CenterLine De México S.

de R.L. de C.V

Av. La Noria #110

Parque Industrial Querétaro,

Santiago de Querétaro, Qro

Mexico CP 76220

MX. +52.442.240.9255

Email: clmxinfo@cntrline.com

CenterLine De Mexico S. de R.L. de C.V-

Hermosillo Region

Carr. La Colorada Km 4.5

Col. Parque Industrial,

Hermosillo Sonora Mexico

MX. +52.442.240.9255

CenterLine Brasil Solda e

Automação Ltda

Rod. BR 280 KM 43 n°501,

Bairro Poço Grande, Cidade de

Guaramirim, Santa Catarina

P.O.Box: n°57

Brasil Cep: 89270-000

Brasil

General: + 55 47 3085 – 8300

Sales: + 55 47 3085 – 8301

Project Mgmt: + 55 47 3085 – 8308

Email: comercial.clb@cntrline.com

CenterLine-Seubert GmbH.

Formerstraße 7,

D-35236 Breidenbach, Germany

DE. +49.6465.911.20

Sales email: cls@cntrline.com

Info Email: cldeinfo@cntrline.com

CenterLine Romania SRL

Str. 13 Decembrie, Nr. 94

Brasov, Romania, 500164

Tel. + 40.268.415004

Mobil : + 40.721.518908

Email: victor.frat[email protected]om

Info email: clroinfo@cntrline.com

CenterLine India Pvt Ltd.

Plot No. 354, Phase IV,

Udyog Vihar, Gurgaon-122016,

Haryana,, India

IN. +91.124.4278267

Email: clin.sales@cntrline.com

CenterLine Welding Technologies

(Guangzhou) Co. Ltd.

68 Huangang Av., Huadu District,

510800

Guangzhou, China

CN. +86-20-6635-6533

Email: clcninfo@cntrline.com

Disclaimer

This document is provided for informational purposes only. Due to the variety of uses for the product illustrated in this

publication, those responsible for the application and use of this product must satisfy themselves that each

application and use of the product meets all applicable laws, regulation codes, and standards. Users of this document

should consult applicable federal, state, and local laws and regulations. CenterLine (Windsor) Limited does not, by

the publication of this document, intend to urge action that is not in compliance with applicable laws, and this

document may not be construed as doing so. CenterLine (Windsor) Limited has made every effort to ensure the

accuracy and completeness of this document; however, because ongoing efforts are made to continually improve the

capabilities of our products, we cannot guarantee the accuracy of the contents of this document. We disclaim liability

for errors, omissions, or future changes herein.

In no event will CenterLine (Windsor) Limited be responsible or liable to any party for any personal injury, property or

other damages of any nature whatsoever, whether special, direct, indirect, incidental, consequential or compensatory,

directly or indirectly resulting from the publication, use of, or reliance on this document, and also from the use of the

equipment described herein.

In issuing and making this document available, CenterLine (Windsor) Limited is not undertaking to render

professional or other services for or on behalf of any person or entity. Nor is CenterLine (Windsor) Limited

undertaking to perform any duty owed by any person or entity to someone else. Anyone using this document should

rely on his or her own independent judgment or, as appropriate, seek the advice of a competent professional in

determining the exercise of reasonable care in any given circumstances.

The illustrations, explanations, charts, and layout examples shown in this publication are intended solely for purposes

of example. Since there are many variables and requirements associated with any particular installation, CenterLine

(Windsor) Limited does not assume responsibility of liability (including intellectual property liability) for actual use

based upon the information given in this publication.

Reproduction of the contents of this copyrighted publication, in whole or part, without written permission of CenterLine

(Windsor) Limited, is prohibited.

© Copyright 2018, CenterLine (Windsor) Ltd. All rights reserved

This page is intentionally left blank.

VeriFastTM MicroView 1.0 – User Manual – Version 1.9

5

Table of Contents

Preface ................................................................................................................................................................. 7

Who Should Use This Manual ...................................................................................................................... 7

Purpose of This Manual................................................................................................................................ 7

Conventions Used in This Manual................................................................................................................ 7

Terminology and Symbols Used Throughout This Manual........................................................................... 8

Safety Information............................................................................................................................................... 9

Important Safety Information ........................................................................................................................ 9

Handling the VeriFast™ MicroView.............................................................................................................. 9

Potential Hazards Related to VeriFast™ MicroView .................................................................................. 10

Equipment and Process Overview .................................................................................................................. 11

Intended Use of Equipment ........................................................................................................................ 11

Technical Specifications ............................................................................................................................. 11

VeriFast™ MicroView Configuration........................................................................................................... 12

5-port Dual Device Controller and Connection Cables ...................................................................... 12

10-port Dual Device Controller and Connection Cables .................................................................... 13

5-port Single Device Controller and Connection Cables.................................................................... 14

Description of I/O........................................................................................................................................ 15

Digital Inputs ...................................................................................................................................... 15

Digital Outputs ................................................................................................................................... 15

Analog Inputs ..................................................................................................................................... 16

Dimensions of VeriFast™ MicroView Controller......................................................................................... 17

Part Ordering Information ........................................................................................................................... 17

Installation Guidelines...................................................................................................................................... 18

Important Safety Information ...................................................................................................................... 18

Mounting the MicroView Unit...................................................................................................................... 18

Installation Precaution for Field Block Applications .................................................................................... 18

Wiring the Ports of VeriFast™ MicroView .................................................................................................. 19

5-port Dual Device Port Configuration ............................................................................................... 19

10-port Dual Device Port Configuration ............................................................................................. 20

5-port Single Device Port Configuration............................................................................................. 22

Pinout Diagram for 4, 5, and 8 Pin Connectors ................................................................................. 22

Setup Scaling .................................................................................................................................................... 23

Changing the Default Passwords .................................................................................................................... 24

Re-Calibrating the Signal Conditioner (If necessary) .................................................................................... 26

6 VeriFastTM MicroView 1.0 – User Manual – Version 1.9

Re-Calibrating the Signal Conditioner for Most Applications...................................................................... 26

Re-Calibrating the Signal Conditioner for Distinct Applications.................................................................. 27

Software Overview ............................................................................................................................................ 28

Screens Navigation Chart........................................................................................................................... 28

Landing Screen / Screen Saver.................................................................................................................. 28

Run Screen................................................................................................................................................. 29

Password Screen ....................................................................................................................................... 30

User Password................................................................................................................................... 30

Maintenance Password...................................................................................................................... 30

Teach Screen ............................................................................................................................................. 31

Step Thru Teach Screen ............................................................................................................................ 32

Maintenance Settings Screen..................................................................................................................... 34

Tolerance Screen ....................................................................................................................................... 35

Scaling Screen ........................................................................................................................................... 36

I/O Test Screen .......................................................................................................................................... 38

USB Storage Screen .................................................................................................................................. 39

System Settings Screen (accessible from More button)............................................................................. 40

Teaching the MicroView ................................................................................................................................... 42

Teaching Positions for VeriFast™ LVDT or VeriFast™ Laser.................................................................... 42

Teaching Positions for LPT ........................................................................................................................ 43

Teaching Positions for Generic Device ...................................................................................................... 43

Maintenance / Troubleshooting ....................................................................................................................... 44

Important Safety Information ...................................................................................................................... 44

Servicing the Lithium Battery...................................................................................................................... 44

Resetting Passwords and Settings to Factory Defaults.............................................................................. 46

Troubleshooting Quick Guide ..................................................................................................................... 47

Decommissioning ............................................................................................................................................. 48

Preparing for Storage ................................................................................................................................. 48

Index.......................................................................................................................................................... Index-1

VeriFastTM MicroView 1.0 – User Manual – Version 1.9

7

Preface

Who Should Use This Manual

Any person installing, using, or maintaining a VeriFast™ MicroView 1.0 controller should use this

manual.

Purpose of This Manual

This manual describes the function, installation, and necessary operating instructions for the

proper use of the standard VeriFast™ MicroView controller. For assistance with any other

customized products or non-standard applications, additional support is available from

CenterLine. Please refer to the inside front cover of this manual for CenterLine contact

information.

To prevent potentially serious or fatal injury, this manual must be read

and understood in its entirety prior to installation, operation, or

maintenance of any VeriFast™ MicroView controller.

While every effort has been made to ensure that the product

descriptions, procedures, and installation requirements included in this

publication are accurate at the time of printing, CenterLine reserves the

right to make product changes that might not be reflected in this

document.

Should you require additional information, please contact CenterLine,

its agents, or distributors for assistance.

Conventions Used in This Manual

This manual uses the following notations:

•Bulleted lists – such as this one – provide information, not procedural steps.

•Numbered lists provide sequential steps to follow or hierarchical information.

•When we refer you to a different section of this manual or to other documentation, the section,

chapter, and publication title appear in italics.

8 VeriFastTM MicroView 1.0 – User Manual – Version 1.9

Terminology and Symbols Used Throughout This Manual

Throughout this manual, all the safety related notes have been identified by the following terms:

This symbol relates information about practices or situations that can

lead to personal injury or death, property damage, or economic loss.

Attention statements help you to:

•Identify a hazard.

•Avoid a hazard.

•Recognize the consequences.

This symbol relates information that is critical for a successful

application and understanding of the product.

This symbol indicates that a serious hazard can occur due to an

explosion.

This symbol indicates that serious hazards can occur due to pinch

points.

This symbol indicates that you should read and understand the

User

Manual and all other applicable instructions before operating the

equipment.

This symbol indicates that the equipment must be disconnected

from all sources of power and put in the lockout state.

This symbol indicates that eye protection must be worn as a

protection against dust, flying objects and particles.

This symbol indicates that appropriate safety shoes must be worn in

order to avoid injuries from exposure to working environment.

This symbol indicates that the equipment must be kept dry,

protected from excessive humidity and rain.

VeriFastTM MicroView 1.0 – User Manual – Version 1.9

9

Safety Information

Important Safety Information

The VeriFast™ MicroView 1.0 controller is used in conjunction with welding equipment and

machinery. Therefore, as a supplement to the safety information offered in this manual for the

VeriFast™ MicroView controller, all the safety considerations that pertain to the equipment used in

conjunction with this device still apply and must be followed thoroughly.

Furthermore, all the existing plant safety regulations and other safety instructions from suppliers

whose components are used with or around the VeriFast™ MicroView controller must be followed

accordingly.

Any instructions contained in this manual that directly conflict with any other known safety

procedures should be brought to CenterLine’s immediate attention for clarification.

•Equipment is not to be modified, adapted, or changed without

consulting the relevant sections of this manual or the manufacturer

(please refer to the inside front cover of this manual for CenterLine

contact information).

•Before any installation, maintenance, or repair work is started, all

sources of energy should be removed from the equipment using

proper LOCKOUT procedures for electrical, pneumatic, and water

services.

•Pneumatic and cooling water lines represent potential hazards.

Ensure all air and water lines are properly connected and secured

prior to turning ON these services.

CAUTION! Risk of explosion if battery is replaced by an incorrect type.

Dispose of used batteries according to the instructions.

Handling the VeriFast™ MicroView

In order to prevent potentially serious personal injury, the VeriFast™ MicroView 1.0 should be

handled, installed, and operated according to the guidelines outlined in this document. Failure to

follow the guidelines set forth here will bear unexpected and potentially dangerous results.

10 VeriFastTM MicroView 1.0 – User Manual – Version 1.9

Potential Hazards Related to VeriFast™ MicroView

The VeriFast™ MicroView system has no specific hazards related to it. However, as the

VeriFast™ MicroView is used in conjunction with other equipment such as welding equipment and

machinery, robot, air supply, etc., the user should be aware of the warnings, hazards, and

precautions related to the use of the equipment as a whole.

Lockout Equipment

•Before starting to install the VeriFast™ MicroView components

on the welding equipment, ensure that the equipment is

disconnected from all sources of power and is in the lockout

state.

•Before turning ON the equipment, make sure all components

are assembled properly.

•Before removing the VeriFast™ MicroView from the welding

equipment, make sure the equipment is turned OFF and is in

the lockout state.

VeriFastTM MicroView 1.0 – User Manual – Version 1.9

11

Equipment and Process Overview

Intended Use of Equipment

The VeriFast™ MicroView 1.0 is a stand-alone controller that allows simple integration of analog

linear position sensing devices into resistance welding systems that require digital I/O.

The VeriFast™ MicroView 1.0 is available in three configurations:

•VeriFast™ MicroView 5-port Dual Device – can integrate up to two (2) of the following

devices:

oVeriFast™ LVDT

o

VeriFast™ LPT

oVeriFast™ Laser

o

Generic device that operates on 0 to 10 V

•VeriFast™ MicroView 10-port Dual Device – can integrate up to two (2) of the devices

listed above.

•VeriFast™ MicroView 5-port Single Device – can integrate only one VeriFast™ LVDT.

No other devices can be integrated with this configuration.

Regardless of configuration, each device must be connected to a channel on the MicroView

controller. For each channel, the user can teach 15 schedules. Every schedule can monitor up to

four (4) linear positions, with a set of independent upper/lower tolerance window that can be

individually set for each position.

The MicroView can output four (4) digital outputs per channel. These digital outputs are controlled

by a nominal position, with tolerances taken into account. When the analog signal is within the

window, the corresponding digital output is HIGH.

In addition to the four digital outputs per channel, each channel has a digital output signal

indicating if the device has been bypassed (Bypassed is logic HIGH).

The On-board storage has the ability to store up to 500,000 points of data per input device.

Technical Specifications

Table 1 – Technical Specifications of VeriFast™ MicroView 1.0

Parameter

Value

Power:

Input Voltage / Current

18 VDC – 30 VDC, 1 A max @ 24 VDC

Digital I/O:

Input

PNP, High True

VIL = 2.4 VDC Max., IIL = 3.0 mA Max., VIH = 30 VDC Max.

Output

PNP, Low True

VOL = 0.8 VDC Max., IOL = 50 mA Max., VOH = 30 VDC Max.

Environmental:

Operating Temperature Range

-20°C to 50°C

Enclosure Size

150 mm x 220 mm x 110 mm (5-7/8 in. x 8-5/8 in. x 4-1/4 in) (Width x Height x Depth)

12 VeriFastTM MicroView 1.0 – User Manual – Version 1.9

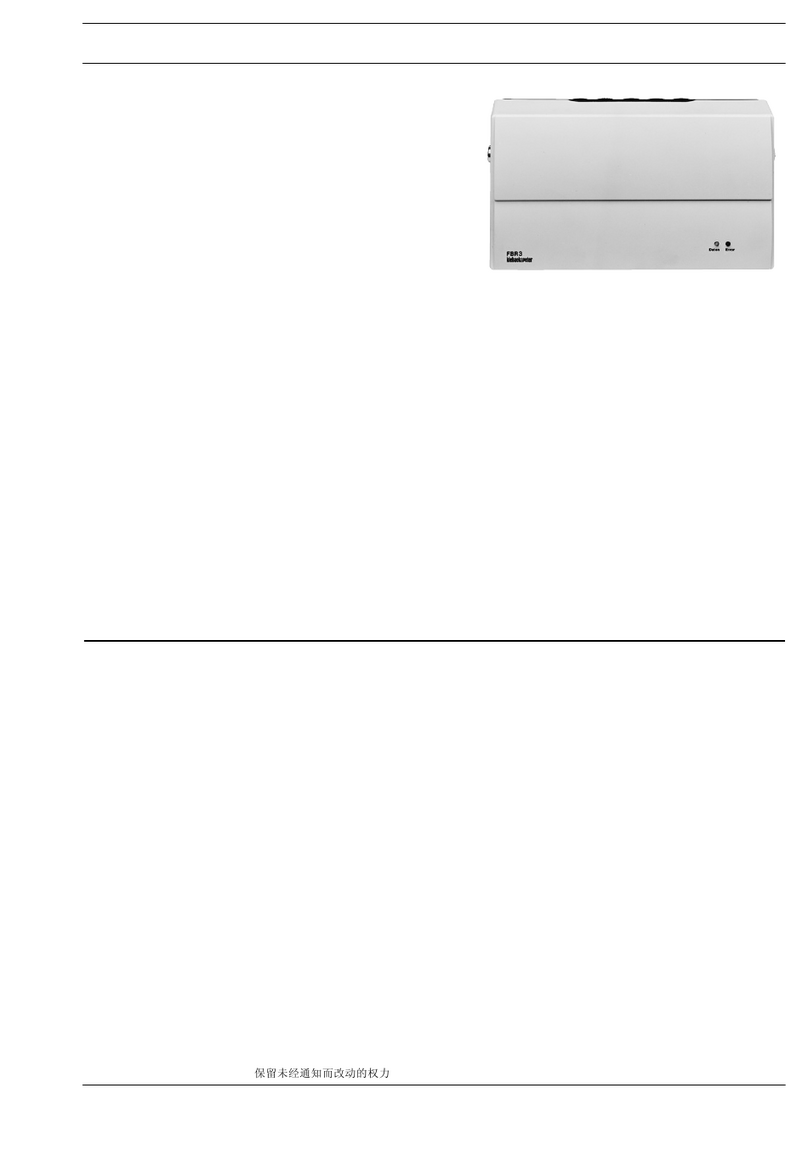

VeriFast™ MicroView Configuration

The three existing configurations of the MicroView controller module are illustrated below, each

with corresponding connection cables.

5-port Dual Device Controller and Connection Cables

Figure 1 – Configuration of VeriFast™ MicroView 5-port Dual Device Controller

For the cables required to connect the VeriFast™ MicroView 5-port Dual Device Controller, see

Table 2 below.

Table 2 – Required connection cables for VeriFast™ MicroView 5-port Dual Device

Type of Cable

Number of Pins

Male/Female

Connection to Port

Number of Cables

M12

5-Pin or 8-Pin **

Male

Device 1, Device 2 (input)

1 or 2

M12

8-Pin

Female

Power/Schedule/Status

1

M12

5-Pin

Male

Output 1, Output 2 (digital)

1 or 2

** Depends on the configuration of the MicroView.

HMI Display

Output Ports* (Digital)

Power/Schedule/Status Control Port *

Devices Ports* (Inputs)

USB Port

* For cable requirements, see Table 2 below.

VeriFastTM MicroView 1.0 – User Manual – Version 1.9

13

10-port Dual Device Controller and Connection Cables

Figure 2 – Configuration of VeriFast™ MicroView 10-port Dual Device Controller

For the cables required to connect the VeriFast™ MicroView 10-port Dual Device Controller, see

Table 3 below.

Table 3 – Required connection cables for VeriFast™ MicroView 10-port Dual Device

Type of Cable

Number of Pins

Male/Female

Connection to Port

Number of Cables

M12

5-Pin or 8-Pin **

Male

Device 1 (input), Device 2 (input)

1 or 2

M12

4-Pin

Female

Power, Device 1 P2, Device 1 P1

1

M12

4-Pin

Female

Power, Device 1 P3, Device 1 P4

1

M12

4-Pin

Female

Device 2 P2, Device 2 P1

1

M12

4-Pin

Female

Device 2 P3, Device 2 P4

1

M12

4-Pin

Female

Teach Mode, Run Mode

1

M12 4-Pin Female

Device 1 Bypass,

Device 2 Bypass

1

M12

4-Pin

Female

Schedule 1, Schedule 2

1

M12

4-Pin

Female

Schedule 4, Schedule 8

1

** Depends on the configuration of the MicroView.

USB Port

HMI Display

Devices Ports* (Inputs)

Input Ports* (Digital)

Output Ports* (Digital)

* For cable requirements, see Table 3 below.

14 VeriFastTM MicroView 1.0 – User Manual – Version 1.9

5-port Single Device Controller and Connection Cables

Figure 3 – Configuration of VeriFast™ MicroView 5-port Single Device Controller

For the cables required to connect the VeriFast™ MicroView 5-port Single Device Controller, see

Table 4 below.

Table 4 – Required connection cables for VeriFast™ MicroView 5-port Single Device

Type of Cable

Number of Pins

Male/Female

Connection to Port

Number of Cables

M12

5-Pin

Male

Device 1

1

M12

4-Pin

Male

CN-1, CN-2, CN-3, CN-4

4

HMI Display

Output Ports* (Digital)

Device Port* (Input)

USB Port

* For cable requirements, see Table 4 below.

VeriFastTM MicroView 1.0 – User Manual – Version 1.9

15

Description of I/O

Digital Inputs

The VeriFast™ MicroView digital inputs are 30 V tolerant PNP inputs. For a 24 V input, the

maximum current drawn will be less than 1 mA.

•Schedule Inputs (4 Bits)

a) Binary 1

b) Binary 2

c) Binary 4

d) Binary 8

Table 5 – Minimum Pin Configuration

Number of Schedules

Required

Configuration

Schedule 1

Schedule 2

Schedule 4

Schedule 8

1

24 VDC

0 VDC

0 VDC

0 VDC

Up to 3

PLC Output

PLC Output

0 VDC

0 VDC

Up to 7

PLC Output

PLC Output

PLC Output

0 VDC

Up to 15

PLC Output

PLC Output

PLC Output

PLC Output

Digital Outputs

The VeriFast™ MicroView digital outputs are PNP outputs and source the voltage present on the

VIN to the device. The digital outputs are solid state driven, with a 10 million cycle rating, and a

maximum current output rating of 100 mA. If draw exceeds 100 mA, a resettable fuse is triggered.

If this happens, it takes approximately 2~5 minutes for the fuse to reset. Each output has

independent fuses, so if one is tripped, the others are still active.

1. Run Enabled – Logic HIGH when device is in an active run state. Active LOW when device is

in a maintenance teach state. Note: This output is not available for 5-port Single Device

configurations.

2. Teach Enabled – Logic HIGH when device is:

a) in a maintenance teach mode

b) in a running teach mode

c) when teach mode is requested.

Note: This output is not available for 5-port Single Device configurations.

3. Outputs for both channel 1 & 2 (Note: Position outputs are only active if there is a schedule

selected (i.e., schedule inputs not zero) and in Run Mode):

a) P1 – Position 1 – Output is HIGH when the analog signal is within the defined tolerance in

reference to taught nominal position. That is:

i. “Pin Extended” – for VeriFast™ LVDT or Laser

ii. “Gun Open” – for LPT

16 VeriFastTM MicroView 1.0 – User Manual – Version 1.9

b) P2 – Position 2 – Output is HIGH when the analog signal is within the defined tolerance in

reference to taught nominal position. That is:

i. “Weld Position” – for VeriFast™ LVDT or Laser

ii. “Weld Position” – for LPT

c) P3 – Position 3 – Output is HIGH when the analog signal is within the defined tolerance in

reference to taught nominal position. That is:

i. “Set Down Achieved” – for VeriFast™ LVDT or Laser

ii. “Double Nuts Present” – for LPT

d) P4 – Position 4 – Output is HIGH when the analog signal is within the defined tolerance in

reference to taught nominal position. That is:

iii. “Pin Retracted” – for VeriFast™ LVDT or Laser

iv. “No Nut Present” – for LPT

e) Bypassed – Output is HIGH when the device has been bypassed. Note: This output is

not available for 5-port Single Device configurations.

Analog Inputs

The two 16-Bit analog inputs are designed for 0-10V operation. These inputs are 30 V tolerant and

are wired specifically for the device that is going to be connected to the MicroView. For example, if

the input is configured for a VeriFast™ LVDT, only an LVDT (and not an LPT or analog device)

can be connected to that input.

For wiring of your particular MicroView, please refer to the information sticker on the side of the

MicroView enclosure (an example is shown in Figure 4 below).

Figure 4 – Example of Information Sticker Affixed to VeriFast™ MicroView

VeriFastTM MicroView 1.0 – User Manual – Version 1.9

17

Dimensions of VeriFast™ MicroView Controller

Figure 5 – Dimensions of VeriFast™ MicroView Controller (all configurations)

Part Ordering Information

The MicroView is marked with labels providing information about your specific configuration. When

ordering a replacement component, please check your own equipment to find that specific part

number. As a reference, see Figure 6 below.

Figure 6 – VeriFast™ MicroView Part Numbering System

18 VeriFastTM MicroView 1.0 – User Manual – Version 1.9

Installation Guidelines

Important Safety Information

Please review the Safety Information section starting on page 9.

Before installation procedure for the MicroView is started, ensure that all

services (e.g., power, air, water) provided to the devices connected to

MicroView are de-energized and locked out.

CenterLine recommends that qualified electrical personnel be involved with the setup and

operation of the MicroView. Also, a qualified weld engineer or quality control personnel should be

available for tolerances adjustments and scaling, when required.

Mounting the MicroView Unit

Using four M4 screws through the mounting holes on the unit’s back plate, mount the MicroView

on a flat surface in a convenient location on machinery or fixture.

Installation Precaution for Field Block Applications

Prior to connecting a MicroView to a field block, it is recommended to disconnect power on the

field block. After the MicroView connections to the field block have been made, it is safe to

reconnect power to the field block.

VeriFastTM MicroView 1.0 – User Manual – Version 1.9

19

Wiring the Ports of VeriFast™ MicroView

5-port Dual Device Port Configuration

Port on MicroView /

Connected Device

Pin Function

Device 1, Device 2 Ports (Inputs)

VeriFast™ LVDT

1

Primary Coil 1

2

Primary Coil 2

3

Secondary Coil 1

4

Secondary Coil 2

5

Shield

Analog / Laser

1

+24 VDC

2

No Connection

3

0 VDC

4

No Connection

5

0-10 VDC Analog Signal

Balluff LPT

1

No Connection

2

0 VDC

3

No Connection

4

No Connection

5

0-10 VDC Analog Signal

6

Ground (0 VDC)

7

+24 VDC

8

No Connection

Output 1, Output 2 Ports (Digital Outputs)

VeriFast™ LVDT / Analog /

Laser

1

P1 – Pin Extended

2

P2 – Weld Position

3

P3 – Set Down

4

P4 – Pin Retracted

5

P5 – Bypassed

Balluff LPT

1

P1 – Gun Opened

2

P2 – Weld Position

3

P3 – Double Nut

4

P4 – Nut Missing

5

P5 – Bypassed

Power / Schedule / Status Port

VeriFast™ LVDT / Analog /

Laser / Balluff LPT

1

Schedule 1

2

+24 VDC

3

Status – Run

4

Schedule 2

5

Schedule 4

6

Schedule 8

7

0 VDC

8

Status – Teach

20 VeriFastTM MicroView 1.0 – User Manual – Version 1.9

10-port Dual Device Port Configuration

Port on MicroView /

Connected Device

Pin Function

Device 1, Device 2 Ports (Inputs)

VeriFast™ LVDT

1

Primary Coil 1

2

Primary Coil 2

3

Secondary Coil 1

4

Secondary Coil 2

5

Shield

Analog / Laser

1

+24 VDC

2

No Connection

3

0 VDC

4

No Connection

5

0-10 VDC Analog Signal

Balluff LPT

Device Type

1

No Connection

2

0 VDC

3

No Connection

4

No Connection

5

0-10 VDC Analog Signal

6

Ground (0 VDC)

7

+24 VDC

8

No Connection

Output Device Ports and Power / Schedule / Status Port

CN-1

VeriFast™ LVDT

1

+24 VDC

2

Device 1, Weld Position

3

0 VDC

4

Device 1, Pin Extended

Analog / Laser

1

+24 VDC

2

Device 1, P2

3

0 VDC

4

Device 1, P1

Balluff LPT

1

+24 VDC

2

Device 1, Weld Position

3

0 VDC

4

Device 1, Gun Opened

CN-2

VeriFast™ LVDT

1

+24 VDC

2

Device 1, Pin Retracted

3

0 VDC

4

Device 1, Set Down

Analog / Laser

1

+24 VDC

2

Device 1, P4

3

0 VDC

4

Device 1, P3

Balluff LPT

1

+24 VDC

2

Device 1, Double Nut

3

0 VDC

4

Device 1, No Nut

This manual suits for next models

3

Table of contents