CRE Technology Gensys Compact Prime Guide

TECHNICAL DOCUMENTATION

2

A56_PRIME_90020-E-EN

Table of c ontent s

Description ........................................................................................................................... 4

Presentation .................................................................................................................................... 4

Front Face ....................................................................................................................................... 6

Rear Face ........................................................................................................................................ 9

Panel Mounting ............................................................................................................................... 10

UL Requirements ............................................................................................................................ 12

Usage ........................................................................................................................................ 18

Password ....................................................................................................................................... 18

LCD ............................................................................................................................................... 19

Wiring ........................................................................................................................................... 21

Digital Inputs .................................................................................................................................. 27

Digital Outputs ................................................................................................................................ 29

Analog Inputs ................................................................................................................................. 30

Settings ................................................................................................................................ 34

Engine ........................................................................................................................................... 34

Circuit Breakers .............................................................................................................................. 38

Speed/Voltage Control .................................................................................................................... 42

Synchronization .............................................................................................................................. 45

Load/Unload Ramp ......................................................................................................................... 48

Regulation KW/KVAR ....................................................................................................................... 49

Protections ..................................................................................................................................... 51

Control Loop PID ............................................................................................................................. 54

Advanced Settings ..................................................................................................... 55

Droop ............................................................................................................................................ 55

Load Dependent Start/Stop .............................................................................................................. 56

Static Paralleling ............................................................................................................................. 59

Load Shedding ............................................................................................................................... 61

Maintenance Schedule .................................................................................................................... 63

Power Plant Application ................................................................................... 64

Load Sharing .................................................................................................................................. 64

Advanced Functions .................................................................................................. 67

Scheduler ...................................................................................................................................... 67

Alternative Selections ...................................................................................................................... 69

Easy Flex® .................................................................................................................................... 71

Modbus TCP Mapping ...................................................................................................................... 73

Logger ........................................................................................................................................... 74

Communications ............................................................................................................ 75

Network ......................................................................................................................................... 75

Modbus TCP/IP ............................................................................................................................... 77

CRE-Link® ..................................................................................................................................... 80

CANopen ....................................................................................................................................... 81

SAE J1939 ..................................................................................................................................... 82

CAN bus Good Practices .................................................................................................................. 89

TECHNICAL DOCUMENTATION

3

A56_PRIME_90020-E-EN

Website .................................................................................................................................... 91

Access ........................................................................................................................................... 91

File Transfer .................................................................................................................................. 92

Firmware Update ............................................................................................................................ 94

Appendices ......................................................................................................................... 95

Analog Voltage Regulation (AVR) ..................................................................................................... 95

ECU J1939 ..................................................................................................................................... 99

Analog Speed Regulation ............................................................................................................... 108

Short Circuit Protection .................................................................................................................. 113

Troubleshooting ............................................................................................................................ 121

Standards for Generator ................................................................................................................ 125

Certifications ................................................................................................................................ 126

Software Variables ....................................................................................................................... 129

TECHNICAL DOCUMENTATION

4

A56_PRIME_90020-E-EN

D es cr ipt ion

Presentation

GENSYS COMPACT PRIME

All-in-one synchronizing and paralleling controller

The GENSYS COMPACT PRIME is made for generators used in Power plant applications requiring

synchronizing, active and reactive load sharing and electrical/mechanical protections.

GENSYS COMPACT PRIME offers flexibility and time saving thanks to its simple wiring, all features included

(no option), and easy engineering and programming.

Hardware and Display

GENSYS COMPACT PRIME is available in both switchboard panel mounted version with display, or core base

mounted version. GENSYS COMPACT PRIME is also compatible with i4Gen touchscreen color display.

Software

GENSYS COMPACT PRIME is configurable from its front panel display, from i4Gen, or through the free CRE

PC software: CRE Config Software.

TECHNICAL DOCUMENTATION

5

A56_PRIME_90020-E-EN

Control and Management

·Complete engine control of diesel, gasoline or gas generators (preheating, pre-glow, ignition, start/stop…).

·Alternative or consecutive multiple starter management.

·Warm-up and cool down at idle or nominal speed.

·Remote start and TEST mode available On/Off load.

·Compatible with all J1939 electronic engines.

·Isochronous and Iso-voltage active and reactive load sharing.

·Fixed KW/KVAR load or Droop mode.

·Frequency and voltage control compensation for generators with droop governors and/orAVR/DVR.

·Synchronization and dead bus management.

·Static synchronization: generators breakers closing without excitation.

·Dynamic synchronization: Frequency, Phase and Voltage synchronization (Synch display available on

screen). Synch check (ANSI 25) + Phase sequence protection.

·New optimized PID loop with exceptional performance in synchronization, KW and KVAR control.

·Override mode (protections inhibition + dedicated hour meter) following NFE 37-312 certification.

·Non-essential load control on overload.

·Battery boost management.

·Configurable maintenance cycles.

·2 password levels.

·Automatic clock synchronization by CAN bus.

TECHNICAL DOCUMENTATION

6

A56_PRIME_90020-E-EN

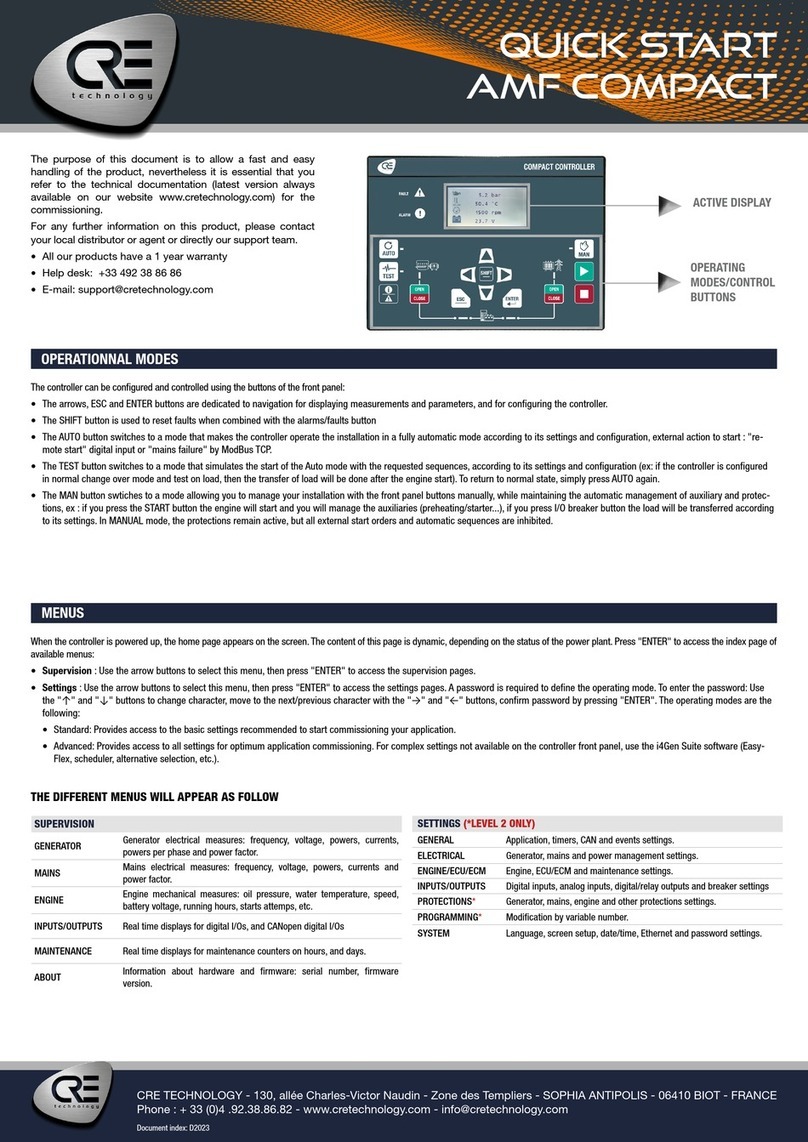

Front Face

GENSYS COMPACT PRIME

PIN Buttons Functions

1 SHIFT button Additional functions.

2 RIGHT button Navigation button (Right).

3 DOWN button Navigation button (Down).

4 LEFT button Navigation button (Left).

5 UP button Navigation button (Up).

6 ENTER button Validating entry/ MENU.

7 ESC button Cancel entry/ escape MENU.

8 INFO button Allows direct access to the current Fault orAlarm display.

9(1) Generator circuit breaker

button

Can onlybe used in MAN mode.

Generator circuit breaker control.

Press to Open. Press to Close (synchronization & load transfer will be

done automatically if Bus is powered & configuration is setup for

paralleling operation).

10(1) Mains circuit breaker button

Can onlybe used in MAN mode.

Mains circuit breaker control.

Press to Open. Press to Close (synchronization & load transfer will be

done automatically if Bus is powered & configuration is setup for

paralleling operation).

TECHNICAL DOCUMENTATION

7

A56_PRIME_90020-E-EN

PIN Buttons Functions

11(1) STOP button

Can onlybe used in MAN mode.

Stop the Generator.

Pressing once this button will set the Generator offload and initiate cooling

down sequence.

12(1) START button Can onlybe used in MANmode.

Start the Generator.

13(1) MAN button MANmode.

The associated LED lights up when the mode is activated.

14(1) TEST button TEST mode.

The associated LED lights up if the mode is activated.

15(1) AUTO button AUTO mode.

The associated LED lights up when the mode is activated.

16 ALARMindicator The LED flashes when an alarm appears.

The LED is lit when an alarm is acknowledged, but not reseted.

17 DEFAULT indicator The LED flashes when a Fault occurs.

The LED is lit when a Fault is acknowledged, but not reseted.

18 LCD display Screen size: 40mm x 70mm; Back-light : typical 50cd/m2, configurable.

Type: STN; 64 x128 pixels.

(1) Not available according to controller type.

Note: Pressing it twice will setthe Generator offload and stop the engine without cooling down sequence.

Navigation keys

Keys Navigation mode Edition mode

Scrolling menus. Modifying parameters values once selected: When

up/down keys are used to modifyvalues, holding the

keywill accelerate the entryscrolling.

Navigating right/left in display. NA

+ will increase/decrease the

brightness of the LCD display.

+ will increase/decrease the

contrast of the LCD display.

In MAN mode, when the Generator is offload, use

to increase/decrease:

§The speed when the speed control page is

displayed.

§The voltage when the voltage control page is

displayed.

Note: Not available on MASTER COMPACT,

MASTER COMPACT 1Band BTBCOMPACT.

Return to parentmenu (press 3 times to return

to main screen) or to previous menu. Cancel setting and return to Navigation mode.

Accessing a menu / Switching to Edition mode. Validation of the modified parameter and return to

Navigation mode.

TECHNICAL DOCUMENTATION

8

A56_PRIME_90020-E-EN

Button inhibition

To inhibit front panel buttons, use the CRE Config Software/System/Button inhibition page. This page shows

the list of front panel buttons, tick the corresponding box to inhibit actions on the button.

Table below shows the 16 bits variable used for remote button inhibition by Modbus, each bit is assigned to a

button:

Variable Label Description

[3557] Inhibit key Each 1-bit inhibits a front panel button.

Relation button/inhibition bit [3557]

External button requests

It is possible to remotely activate button actions by Modbus TCP, for a remote manual control for example.

If a button action is controlled by Modbus TCP, the last request received (external or from the front panel) is

treated in priority and cancel the previous request.

MAN / AUTO: If the 2 modes are requested, the MAN mode request cancels the AUTO mode one.

The buttons on the front panel can be replaced by external commands via digital inputs.

Modbus TCP/IP

Modbus mapping

TECHNICAL DOCUMENTATION

9

A56_PRIME_90020-E-EN

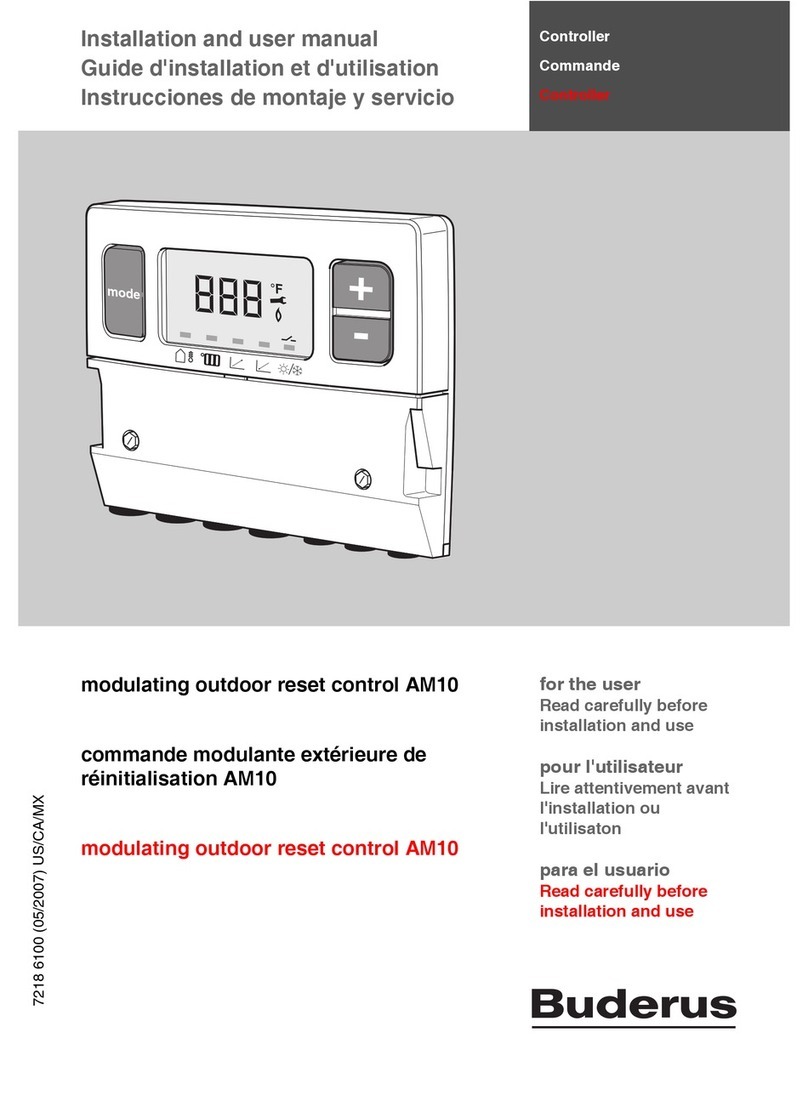

Rear Face

GENSYS COMPACT PRIME

Simplified Wiring Diagram

TECHNICAL DOCUMENTATION

10

A56_PRIME_90020-E-EN

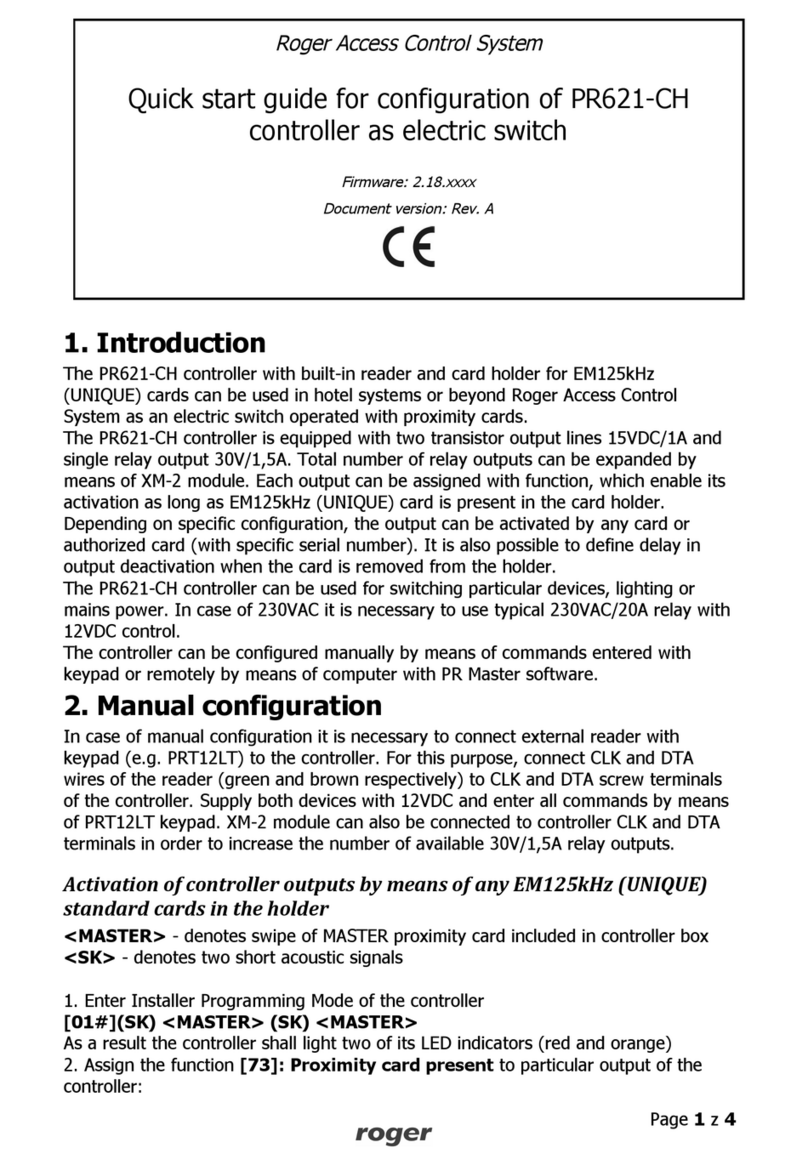

Panel Mounting

The unit is designed for panel mounting, which provides user with access only to the front panel.

WARNING

THE UNIT IS NOT GROUNDED

·Take all measures against Electronic Static Discharges.

·Do not try to open the unit.

Failure to follow these instructionsmay damage the unit.

Environmental requirements:

·Operating temperature: -20…70°C (-4...158°F); LCD display slows down a bit under -5°C (23°F). Avoid direct

exposure to the sun.

·Storage temperature: -40...70°C (-40...158°F).

·Altitude: ≤ 4000m (13123ft) for a max AC voltage of 480VAC; ≤ 5000m (16404ft) for a max AC voltage of

400VAC.

Unpacking

Make sure the packaging contains:

·The unit.

·Four caps and screws packaged apart.

·A delivery bill.

Unpack and keep the packaging in case of return.

Make sure the unit does not show scratches or visible defaults. Otherwise describe them on the RMA sheet

(available on CRE Technology website) and return it with the product to CRE Technology.

TECHNICAL DOCUMENTATION

11

A56_PRIME_90020-E-EN

Installation

Preparation

·Open type devices to be installed inside a suitable type rated enclosure.

·Torque of mounting brackets: 0.4Nm.

·Cut out the panel to 220x160mm (8.7x6.3in) minimum.

·Make sure the cut-out is smooth and clean.

Mounting

TECHNICAL DOCUMENTATION

12

A56_PRIME_90020-E-EN

UL Requirements

ADVANCED WIRING DIAGRAM

Circuit separation

The communication, sensor, and/or battery derived circuit conductors shall be separated and secured to

maintain at least 1/4” (6mm) separation from the Generator and the Bus connected circuit conductors unless all

conductors are rated 600V or greater.

TECHNICAL DOCUMENTATION

13

A56_PRIME_90020-E-EN

Mains Ratings

Over-voltage Category

III, 300VAC system voltage.

Sensing Generator / BusVoltage Measurement (J4)

300VAC max P-N, 2 phases; 500VAC P-P 3 phases, 35...75Hz.

Current Inputs (J5)

Must be connected through listed or recognized isolating current transformers with secondary rating of 5A max

50/60Hz. (XODW2.8) Instrument transformers (according to IEEE C57.13 series or the equivalent).

Communication Circuits

Must be connected to communication circuits of UL Listed equipment.

Output Pilot Duty (J3)

250VAC, 5A max general purpose, 240VAC, 1/4HP for NO contact, 1/6HP for NC contact Pilot duty: C150,

C300.

Digital outputs(J1)

FET: Fuel shutoff: 63VA, 1.8Amax current.

TECHNICAL DOCUMENTATION

14

A56_PRIME_90020-E-EN

Other circuits ratings

Block and mark Description Note

Breaker commands Normallyopen. Breaking capacity: 5A,

240VAC.

Relay1 Relay1 +

Relay1 –

Relay2 Relay2 +

Relay2 –

AC voltage (1) 100...480VAC, 35…75Hz, 100mAmax;

accuracy: 1% fsd.

N Generator N Optional.

L3 Generator L3 These lines must be protected externally

with 100mA/600VAC fuses.

L2 Generator L2

L1 Generator L1

N Bus N Optional.

L3 Bus Phase 3 These lines must be protected externally

with 100mA/600VAC fuses.

L2 Bus Phase 2

L1 Bus Phase 1

Current inputs(1) Short-circuit protection available.

Bus common GND GND.

Bus current I1 Bus I1

0…5A. Maximum rating: 15Aduring 10s.

Burden: 1VA. Keep the lead length short to

preserve accuracy(up to 0.5% full scale

deviation).

External CTmaxratio is 3250 (i.e. 3250:1

or, preferably, 16250:5).

On GENSYS COMPACT PRIME, this input

must be used onlyfor the earth fault

protection.

On GENSYS COMPACT MAINS and AMF

COMPACT, if Mains power measurement

is configured as 20mA, this input can be

used as an earth current measurement.

Generator current I3 Generator I3 0…5A. Maximum rating: 15Aduring 10s.

Burden: 1VA. Keep the lead length short to

preserve accuracy(up to 0.5% full scale

deviation).

External CTmaxratio is 3250 (i.e. 3250:1

or, preferably, 16250:5).

Generator current I2 Generator I2

Generator current I1 Generator I1

Generator common GND Optionallyconnected to CT –.

Analog inputs 0...500W .

Common Connect it to battery-.

Input 3 Available input

Input 2 Available input

TECHNICAL DOCUMENTATION

15

A56_PRIME_90020-E-EN

Block and mark Description Note

Input 1 Available input

Shield GND Ground plane.

(1) Not available according to controller type.

Block and

mark Description Notes

7...38VDC Not protected against polarityreversal.

-Power

supply- 2.5mm² (AWG13).

+Power

supply+ 7…38VDC, consumed current: 130mAat 24V(standbyand operation).

Shield GND Ground ofthe Generator.

Digital

outputs

Free solid state output.State 1 at the supplyvoltage (max: 1.8A). Protected against

short circuits. Areactive load is supported. Not isolated from power.

1

Available

outputs

2

3

4

5

6

Digital inputs

Free digital input with 10kΩ pull-up. Accepts NO or NC contact to 0V. Not isolated from

power.

1

Available

inputs

2

3

4

5

6

7

8

9

CAN2:

J1939-

Extensions Isolated CAN bus J1939 / CANopen. Twisted pair.

CAN L Blue wire.

CAN H White wire.

Resistor - Strap to CAN H when inner resistor must be inserted (bus ends).

Shield 0V Connectthe cable shield herein.

Speed (1) Compatible with all analog speed controllers. Isolated from power supply.

Out Speed output Analog output±10Vto speed controller.

common Speed

reference Twisted pair; length. < 5m (16ft) if unshielded, < 50m maxif shielded.

AVR (1) Compatible with most voltage regulators. Isolated from power supply.

TECHNICAL DOCUMENTATION

16

A56_PRIME_90020-E-EN

Block and

mark Description Notes

Out AVR output + Analog output±10Vto voltage regulator.

Common AVR output –Twisted pair; length. < 5m (16ft) if unshielded, < 50m maxif shielded.

CAN1:CRE-

Link® (1) Isolated CAN bus, use twisted pair.

CAN L White wire with blue strip (when using a CRETechnologycable).

CAN H Blue wire with white strip (when using a CRETechnologycable).

Resistor - Strap to CAN H when inner resistor must be inserted (bus ends).

Shield 0V Connect the cable shield herein.

Pickup (1) 100Hz....10kHz. Voltage limits between + and –: 2...40VAC.

Speed measurement for speed regulation, crank drop out and over-speed. Better

option than alternator voltage.An over-speed shutdown device independent of the

module is required;the alarm can be generated byECU or bythe module.

Pickup +

Pickup –

(1) Not available according to controller type.

Overcurrent protection (DC supply and L1, L2, L3, N)

Installer shall protect DC supply and L1, L2, L3, N by fuse Type: R/C (JDYX2/7), or R/C (JDYX2) and CSA

Certified Class 1422-30.

Rating of fuses:

·DC supply to be protected by 5A, 40VDC max.

·L1, L2, L3, N, fuse protection 100mA/600VAC max.

Terminals Wiring

Terminal (screw type):

·Tightening Torque: 3.5lb.in (0.4Nm).

Wires :

·28-14 AWG, Cu, 75°C min.

Conductor protection must be provided in accordance with NFPA 70, Article 240.

Low voltage circuits (35VDC or less) must be supplied from the engine starting battery or an isolated secondary

circuit.

Environment

Device must be installed in an unventilated or filtered ventilation enclosure to maintain a pollution degree 2

environment.

Maximum surrounding air temperature rating: 45°C.

TECHNICAL DOCUMENTATION

17

A56_PRIME_90020-E-EN

Installation

Preparation

·Open type devices to be installed inside a suitable type rated enclosure.

·Torque of mounting brackets: 0.4Nm.

·Cut out the panel to 220x160mm minimum (8.7x6.3in).

·Make sure the cut-out is smooth and clean.

Mounting

TECHNICAL DOCUMENTATION

18

A56_PRIME_90020-E-EN

Usage

Password

ADVICE

USEFUL INFORMATION

§Adjustment tip

§Using the module

Failure to comply with these recommendations may cause the module to malfunction.

The menus will be automatically locked if no operation isperformed during the time set in the

System menu (Factory setting: 5 minutes).

The standby screen will be displayed.

The module provides secured password access to protect configuration changes and limit data accessibility:

Level Default password Authorization Accessible pagesand

items

0 No password. Press

By default, this level is

not password protected,

but you can implement

one.

Display menu pages

only.

1 1 User level, settings and

commissioning.

Display, Configuration

and System menus

pages.

2 1234 Used to change

advanced settings. Advanced settings (CRE

Config Software only).

Passwords can be changed via CRE PC software: CRE Config Software

To access the Display menu, press .

To access the Configuration and System menus, the padlock must be released:

1. Press to select Configuration or System.

2. Press to switch to password input mode (as for other settings); the first character is

represented by a cursor.

3. Change the character by pressing

4. Move to the next character by pressing

5. Repeat the operation for each character.

6. Confirm the password by pressing

TECHNICAL DOCUMENTATION

19

A56_PRIME_90020-E-EN

LCD

Navigation

Press then and type in the level 1 password as described above to access the top level

menu:

A black pointer spots the currently selected item/setting.

Three main menus are available on the LCD screen and in CRE Config Software:

·Display gives information on Generator/Bus and displays real-time information/status.

·Configuration is used to adjust the settings done previously withCRE Config

Software /Configuration.

·System is used to adjust the settings done previously withCRE Config Software /System

(Date/Hour, screen features, ...).

To cycle through the menus and menu items, press or

To cycle through the pages of lists of settings/readings, press or

Edition

To change a setting:

1. Navigate to the setting.

2. Press to switch to Edition mode; the current value blinks.

3. Press or to get the new value.

4. Press to validate the new value, to reject it. Module returns to Navigation mode.

It is also possible to change settings using Modbus TCP.

Dedicated pages

Dedicated pages include:

·Active fault and archive pages.

·Active alarm and archive pages.

·The information pages.

At any time, faults/alarms/information can be displayed on the LCD screen by pressing the button .

If a fault is active and has not been acknowledged yet, the active fault page will be displayed.

Otherwise, if an alarm is active and has not yet been acknowledged, the active alarms page will be displayed.

Otherwise the information page will appear.

It is then possible to navigate through these dedicated pages using the arrow buttons.

TECHNICAL DOCUMENTATION

20

A56_PRIME_90020-E-EN

To return to the previous page, press or .

EVENTS

Up to 15 active events and 30 archived events can be displayed on the screen.

Each event is time-stamped as follows:

jj/mm/yy hh:mn:ss protec. label On (or Off).

To reset events, press +

Note: Correct the condition that triggered the protection before performing a reset; if necessary, the protection

will trip again.

Information

These pages allow to display the power and engine current state with the associate elapsed time in this state.

Power [4000] displays the unit current state regarding power management.

Engine [4001] displays the unit current state regarding the engine.

Custom variables: to display any variable, enter the code of the variable to be displayed.

Table of contents

Other CRE Technology Controllers manuals

Popular Controllers manuals by other brands

Pololu Corporation

Pololu Corporation Baby Orangutan B-48 user guide

cashco

cashco D Installation, operation & maintenance manual

TraffiCast

TraffiCast BlueTOAD Spectra quick start

IC ELECTRIC

IC ELECTRIC SCL 33 DA 4015BP quick start guide

Basler

Basler APR 63-5 instruction manual

EFI

EFI K Performance Tiny O2 user manual