WARNING:

When using electric tools, machines or1.

equipment, basic safety precautions should

always be followed to reduce the risk of re,

electric shock, and personal injury.

Keep work area clean. Cluttered areas2.

invite injuries.

Consider work area conditions. Do not3.

use machines or power tools in damp,

wet, or poorly lit locations. Do not expose

equipment to rain. Keep work area well

lit. Do not use tools in the presence of

ammable gases or liquids.

Keep children away. All children should be4.

kept away from the work area.

Guard against electric shock. Prevent body5.

contact with grounded surfaces such as

pipes, radiators, ranges, and refrigerator

enclosures.

Stay alert. Never operate equipment if you6.

are tired.

Do not operate the product if under the7.

inuence of alcohol or drugs. Read

warning labels on prescriptions to

determine if your judgment or reexes

might be impaired.

Do not wear loose clothing or jewelry as8.

they can be caught in moving parts.

Wear restrictive hair covering to contain9.

long hair.

Use eye and ear protection. Always wear:10.

-ANSI approved chemical splash goggles

when working with chemicals.

-ANSI approved impact safety goggles at

other times.

-ANSI approved dust mask or respirator

when working around metal, wood, and

chemical dusts and mists.

-A full face shield if you are producing metal

or wood lings.

Keep proper footing and balance at all11.

times.

Do not reach over or across running12.

machines.

Always check that adjusting keys and13.

wrenches are removed from the tool or

machine work surface before plugging it in.

Do not carry any tool with your nger on 14.

either the start button or trigger.

When servicing, use only identical15.

replacement parts.

Check for damaged parts. Before using16.

any tool, any part that appears damaged

should be carefully checked to determine that

it will operate properly and perform its intended

function.

Check for alignment and binding of all moving17.

parts, broken parts or mounting xtures and any

other condition that may affect proper operation.

Any part that is damaged should be properly

repaired or replaced by a qualied technician.

Never force the tool or attachment to do the18.

work of a larger industrial tool. It is designed to

do the job better and more safely at the rate for

which it was intended.

IF THERE IS ANY QUESTION ABOUT A CONDITION

BEING SAFE OR UNSAFE, DO NOT USE THE

TOOL.

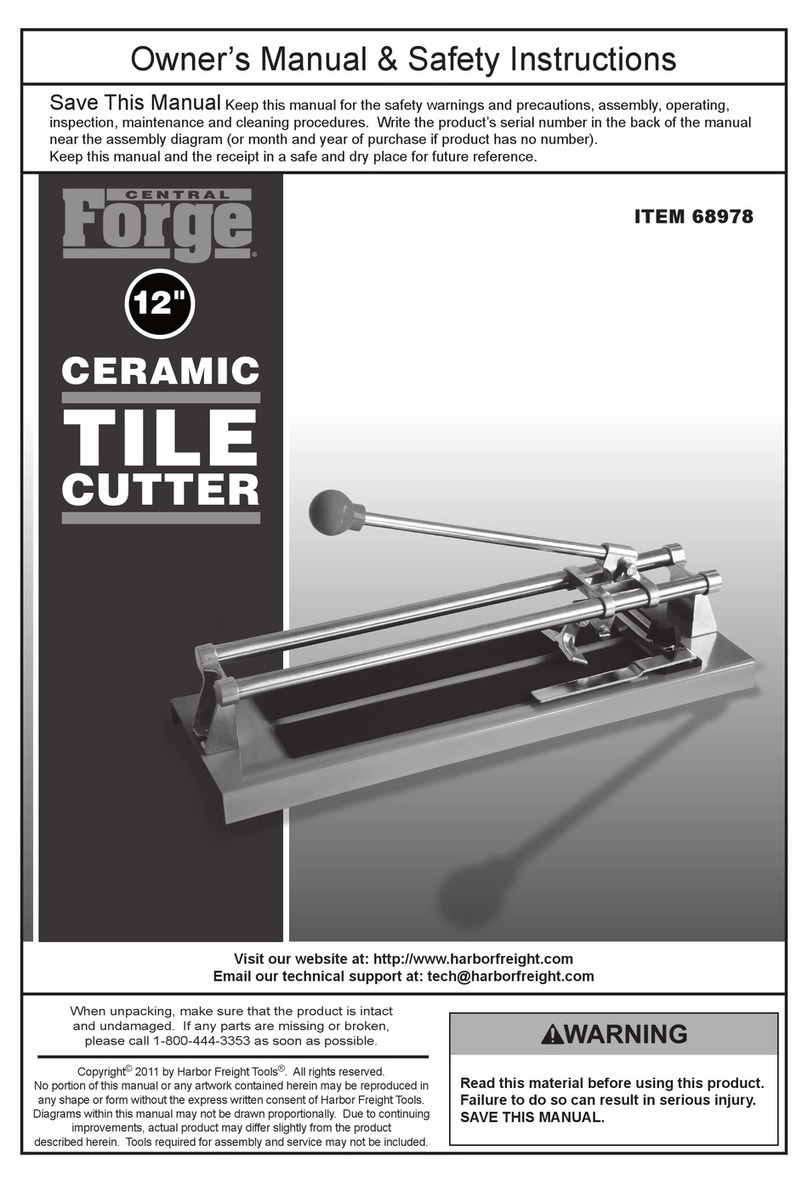

OPERATING THE TILE CUTTER

Refer to the Parts Diagram and Part Number Listing

while performing the following steps.

To make straight cuts on tile, perfom the following

steps:

Mark with a soft carpenter’s pencil the location1.

where the tile cut is planned. Place the tile

against Try Square (L), with the glazed side

up. The pencil line should be straight under the

Cutting Wheel (C).

Hold the tile rmly and cut with the Cutting 2.

Wheel a number of times across the pencil line.

Raise the Lever Rod, and position the tile so that3.

the front edge of the pencil line is lined up with

the edge of the Breaking Part (D). Press down

rmly on the Lever Rod to split the tile along the

pencil line.

Note: The cutting action occurs by moving the

Sliding Frame from the back to the front each time

and pressing down on the Lever Rod slightly. At the

end of the cutting motion, raise the Lever Rod and

Breaking Part, and move it backwards. Repeat this

cutting action a number of times, depending on the

thickness of the tile, until a scored line appears.

#38173 Page 3