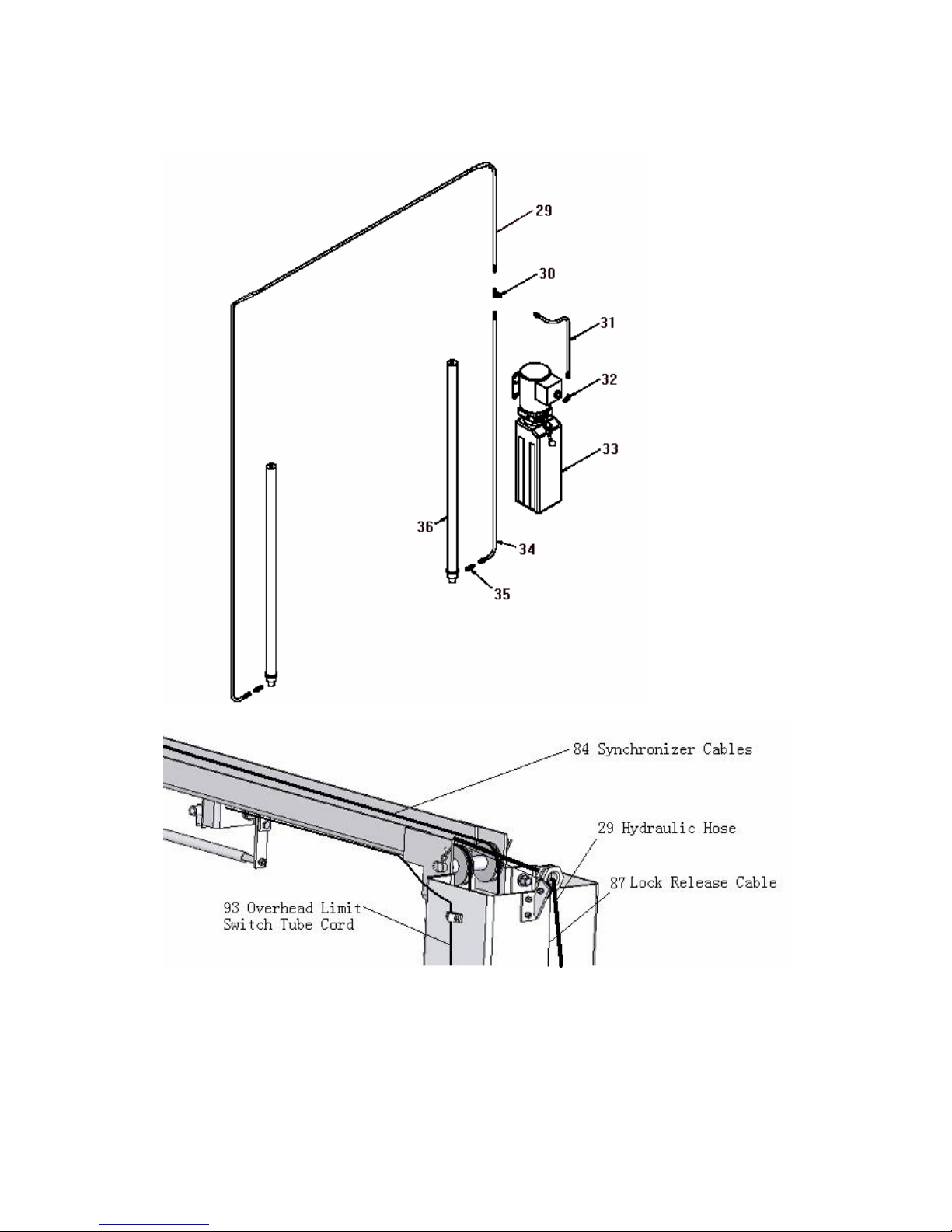

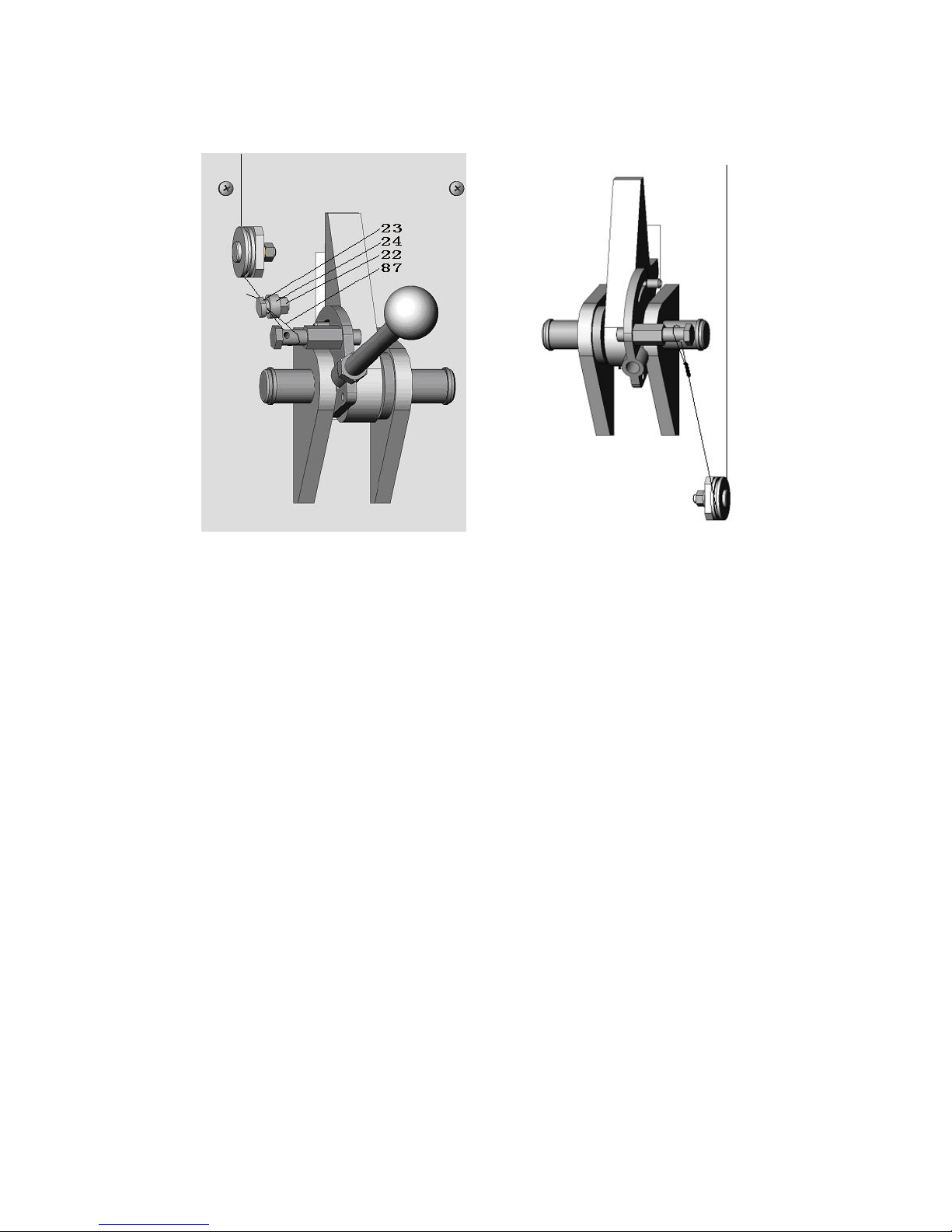

35. Lowerlifttothefloor.Pull andreleaselockreleasehandlewhilewatchingidlercolumnlock.

Adjustthreadedsleevecableadjusternutsuntilidlercolumn lockdisengagesandengagesfully.

Whenproperlyadjusted,theidlercolumnlockshouldjustcometorestagainstthebackofthe

column whenengagedandfullyoutagainstthetabwhendisengaged.

IMPORTANT:IFIDLERSIDELOCKPAWLDOESNOTFULLYDISENGAGE,DAMAGE

MAYRESULT TOIDLERSIDE CARRIAGEAND ORCABLESYNCHRONIZINGSYSTEM.

36. Tightenandtrimwireties.

37. Snaplockcoverovereachlockassembly.

OPERATIONPROCEDURE

SAFETYNOTICESANDDECALS

Thisproductisfurnishedwithgraphicsafetywarninglabels, whichare reproducedonpage3of

theseinstructions.Donotremoveordefacethesewarninglabels,orallowthemtoberemovedor

defaced.Foryoursafety, and thesafetyofothers, readand understandall ofthesafetynoticesand

decalsincluded.

OWNER/EMPLOYERRESPONSIBILITIES

Theowner/employershall makesurethatall liftoperatorsarequalifiedandtrainedinthesafeuseand

operationoftheliftinaccordancewiththemanufacturer soperatinginstructions.Theyalsoshall

displaytheliftmanufacturer soperatinginstructionsandmaintenancescheduleinaconspicuous

locationandarea,convenienttotheoperator.

Theowner/employershall establishprocedurestoperiodicallyinspectandmaintaintheliftin

accordancewiththeliftmanufacturer s suggestions. Theemployershall insurethattheliftinspectorand

maintenance personnelarequalifiedandthattheyareadequatelytrainedintheseprocedures.The

employershall maintaintheseperiodicinspectionandmaintenancerecords.

LIFTINGAVEHICLE

1) Insurethattheliftingarms areparked,outtofull drivethruposition.

2) Positionthevehicleintheservicebaysothatthevehicle scenterofgravityisonalinebetweenthe

twocolumns, andsothevehicleiscenteredbetweenthetwocolumns.

DONOTEXCEED2500POUNDSPERARM.

DONOTATTEMPTTOLIFTTHEVEHICLEWITHONLYTWOARMS,ASTHISWILL

VOIDTHEWARRANTY

INSURETHATTHEHIGHESTPOINTONTHEVEHICLEWILL CONTACTTHE

OVERHEADLIMIT SWITCHBAR

DONOTPLACETHEVEHICLE INTHE SERVICEBAYBACKWARDS.

3) Position thearmsandadapterssoallfourpadscontactthevehiclesimultaneously.

Thevehicleshouldremainlevelduringlifting.

4) Raisetheliftuntil allfourwheelsareofftheground.Testthestabilityofthevehiclebyattempting

torockthevehicle.Checkadaptersforsecurecontactwithvehicleliftpoints.Ifthevehicleseems

unstable,lowertheliftandreadjustthearms.If thevehicleisstable,raisethevehicletoaheighta

fewinchesabovethedesiredworkingheight.

5) Lowerthevehicleuntilthesafetylatchesonbothcolumnsengage.Thevehicleshouldremainlevel

whenbothlatchesareengaged.Ifonesideengagesandtheothercontinuestodescend,stop

loweringthevehicle, raiseitseveralinches, andtryagaintoengagebothlatches.

Always lower liftintolocks beforeenteringtheareabeneaththevehicle.

Alwaysusesafetystandswhenremovingorinstallingheavycomponents.