4

!

!WARNING

•Study, understand, and follow all printed

materials provided with/on this product before use

.

•Do not exceed rated capacity.

•Use only on hard, level surface.

•This is a lifting device only! Immediately

after lifting, support the forklift with a pair of

appropriately rated forklift stands.

• Position jack perpendicular to the forklift such that

the load is balanced by the remaining two wheels

in contact with surface.

• Only attachments and/ or adapters supplied by

the manufacturer shall be used.

•

Do not move or dolly the vehicle while on the jack.

• No alterations shall be made to this product.

FAILURE TO HEED THESE MARKINGS MAY

RESULT IN PERSONAL INJURY AND/OR

PROPERTY DAMAGE

To avoid crushing and related injuries:

•Never work on, under or around a load

supported only by hydraulic forklift jack.

•Always use adequately rated forklift stands.

• Keep hands, feet and all other body parts out of

the area of the scissors mechanism at all times.

•Do not use this device to lift, level, lower,

support nor move a house, mobile home, travel

trailer, camper or any building structure.

•Be alert and sober when using this product.

Do not operate under the inuence of drugs or

alcohol.

!WARNING

OPERATION

Lifting

WARNING: Ensure hydraulic unit does not

contact vehicle during lift event.

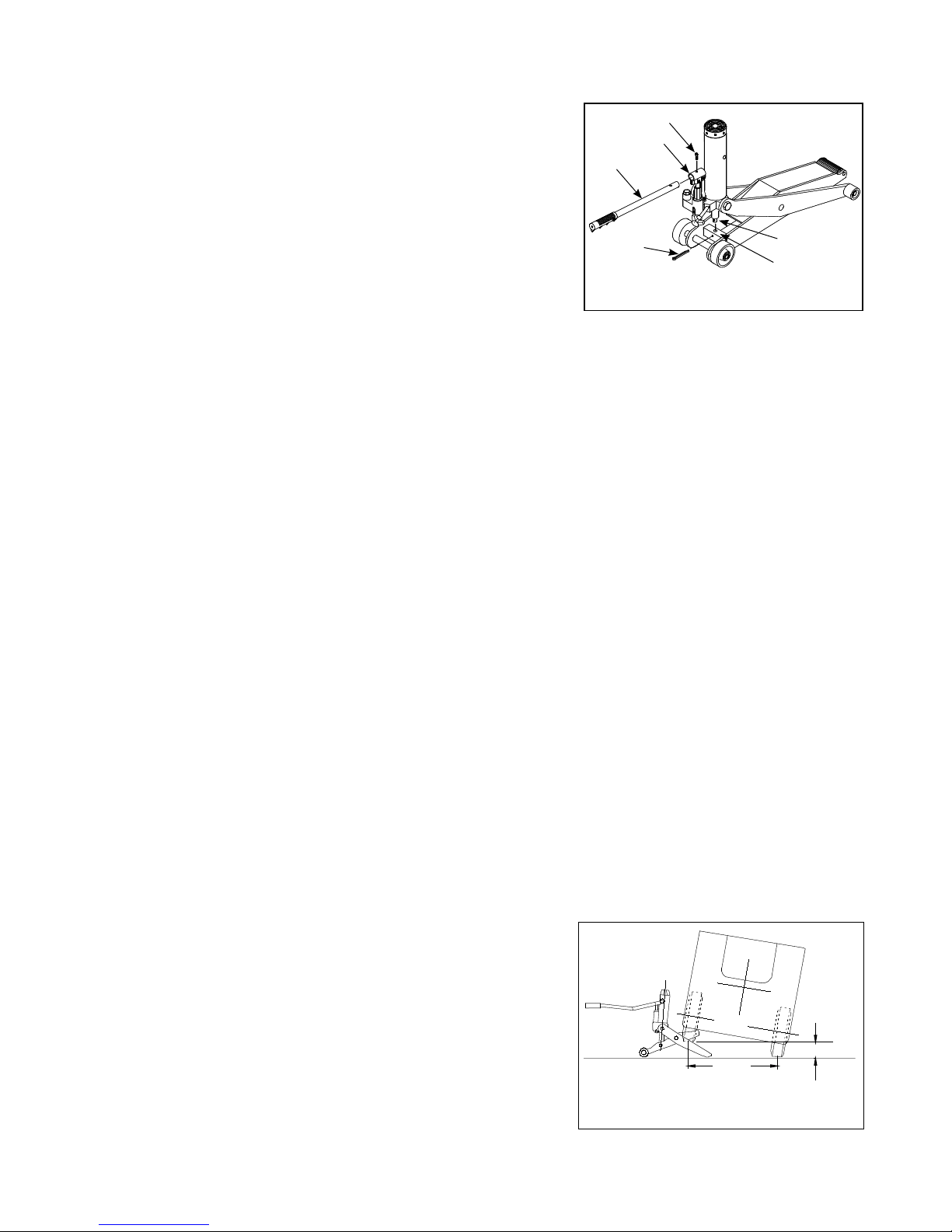

1. Follow the vehicle manufacturer’s recommended

guidelines for lifting. Engage the emergency brake

and chock each unlifted wheel in both directions to

prevent inadvertent vehicle movement.

2.

Close the release valve by turning it clockwise until rm

resistance is felt.

3. Verify lift point, center jack saddle under lift point.

4. Squeeze the lift control valve

(model 28047 only)

or

insert handle into handle sleeve and pump to contact

lift point. To lift, continue pumping until load reaches

desired height.

NOTE: for model 28047, DO NOT operate by air and

by hand pumping at the same time.

5. Transfer the load immediately to appropriately rated

forklift stands.

WARNING:

NEVER use hydraulic jack as a

stand alone

device! ALWAYS transfer the lifted

forklift

IMMEDIATELY to a pair of appropriately

rated forklift stands. Use one pair of forklift stands

per forklift. Rated capacity is per pair only! Do

not exceed rated capacity.

!

X

!WARNING

Never lift from either end of forklift

!WARNING

Lift only on areas of the forklift as

specied by the forklift manufacturer.

Lowering

WARNING:

Be sure all tools and personnel are

clear before

Lowering load. Slowly open the

release valve! The more you turn the knob

counter-clockwise, the faster the load will come

down. Maintain control of the rate of speed at

which the load lowers at all times!

1. Raise forklift high enough to clear the forklift stands.

2.

Remove stands carefully (always used in pairs).

3. Slowly turn the release valve counter-clockwise, but

no more than 1/2 full turn. If the load fails to lower:

a. Use another jack to raise the forklift high enough

to reinstall forklift stands.

b. Remove the malfunctioning jack and then the

forklift stands.

c.

Using the functioning jack to lower the

forklift.

4. After removing jack from under the forklift, fully lower

the saddle and push handle sleeve down to reduce

ram and piston exposure, rust and contamination.

!