Power Towers Nano Owner's manual

Power Towers Ltd,

West House, West Avenue, Wigston, Leicester LE18 2FB, United Kingdom, Tel: +44 (0)116 200 1757, Fax: +44 (0)116 284 9243

Working Dimensions

Maximum working height: 4.50 m

Maximum platform height: 2.50 m

Platform dimensions: 1.00 m x 0.73 m

Working footprint: 1.19 m x 0.75 m

Safe working load: 200 kg (1 person plus tools)

Maximum manual force: 200 N

Max. gradient for operation: 0°

Max. wind force: Indoor use 0 mph

Manual push force on level ground: 9 kg

Maximum total weight inc payload: 485 kg

Maximum castor point load: 180 kgs (1.77 kN)

Max. wheel force: 1.75 kN

Closed Dimensions

Length: 1.195 m

Width: 0.750 m

Height: 1.560 m

Weight: 285 kg

Power Source

Standard 12v DC Electric Motor

Or 240V AC Electric Motor 13A Supply

Or 110V AC Electric Motor 16A Supply

Battery Charger Specification

Input Voltage:

If single voltage: 90-135V AC (UK)

180-265V AC (non-UK)

If dual voltage: 90-265V AC

Frequency: 45-65 Hz

Output: 12V DC, 7A

Power sound level: Less than 70dB

2

Content

Page

3 – 4 Battery Maintenance

5 Battery Charging Fault

6 Checking for Oil Leaks

7 How to Change the Oil in the Hydraulic System

8 Adjusting the Wear Screws (Mast Section)

9 Castor and Wheel Maintenance

10 Replacement of Castor Wheel

11 Gate Latch Adjustment

12 – 13 Removing or Replacing the Hydraulic Pipe

14 – 15 Remove or Replace the Emergency Lowering Valve

16 – 18 Removing or Replacing the Lift Cylinder

19 – 20 Removal and Assembly of the Telescopic Mast

3

Battery Maintenance

Please ensure,the unit is isolated and you use the correct PPE as indicated.

Check the electrolyte level in each of the

battery cells. The electrolyte should be

covering the plates by one to two

millimetres

Check the connections and make sure the

battery is clean

Using a hydrometer, check the specific

gravity of each cell in the battery. The

hydrometer should read between 1.28

and 1.285, and all cells should be equal.

4

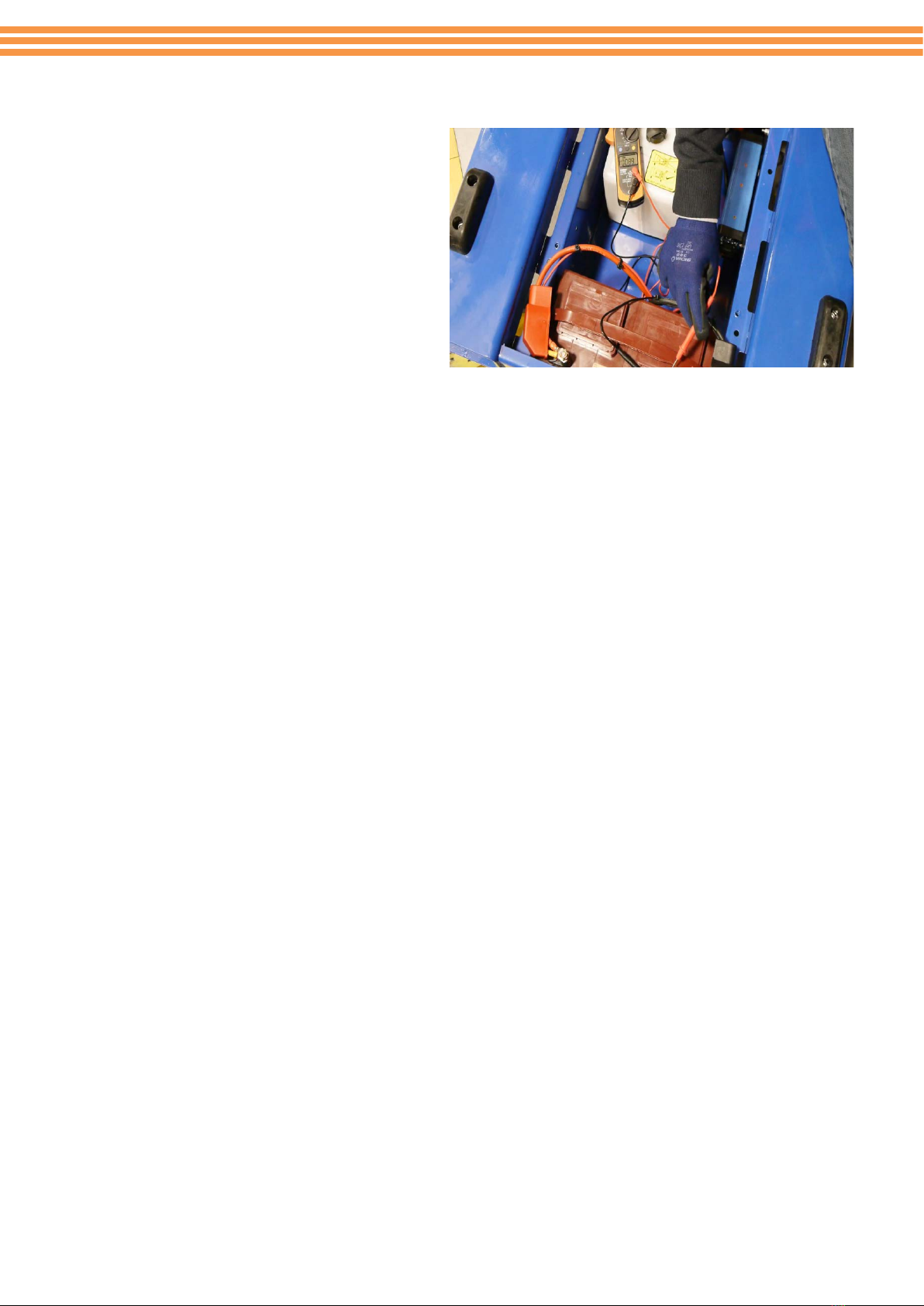

Use a voltmeter to check the voltage. The

reading should be approximately 13 volts.

5

Battery Charging Fault

Please ensure,the unit is isolated and you use the correct PPE as indicated.

Check the battery charger lights when

first switched on (Display Green LED On,

Amber LED blinking fast is bulk load,

blinking slow is absorption, on float, off

storage.)

If the both charger lights flash slowly,

check the fuse, battery connections and

then the battery condition as outlined in

the chapter: ‘Battery Maintenance.

Fuse can be found underneath the fuse

cover on the charger.

Fuse cover can be identified by the red

arrow.

If there are no lights on the charger,

check the supply connections which can

be found on the right hand side of the

chassis

6

Checking for Oil Leaks

Please ensure,the unit is isolated and you use the correct PPE as indicated.

Remove covers spine end cap and the

chassis top cover and check the pipe end

connections at the base of the lift

cylinder ensure the union is torque to

40Nm and also check the connections on

top of the power pack.

Check the lowering valve spool and the

valve screw cartridge on the side of the

power pack.

7

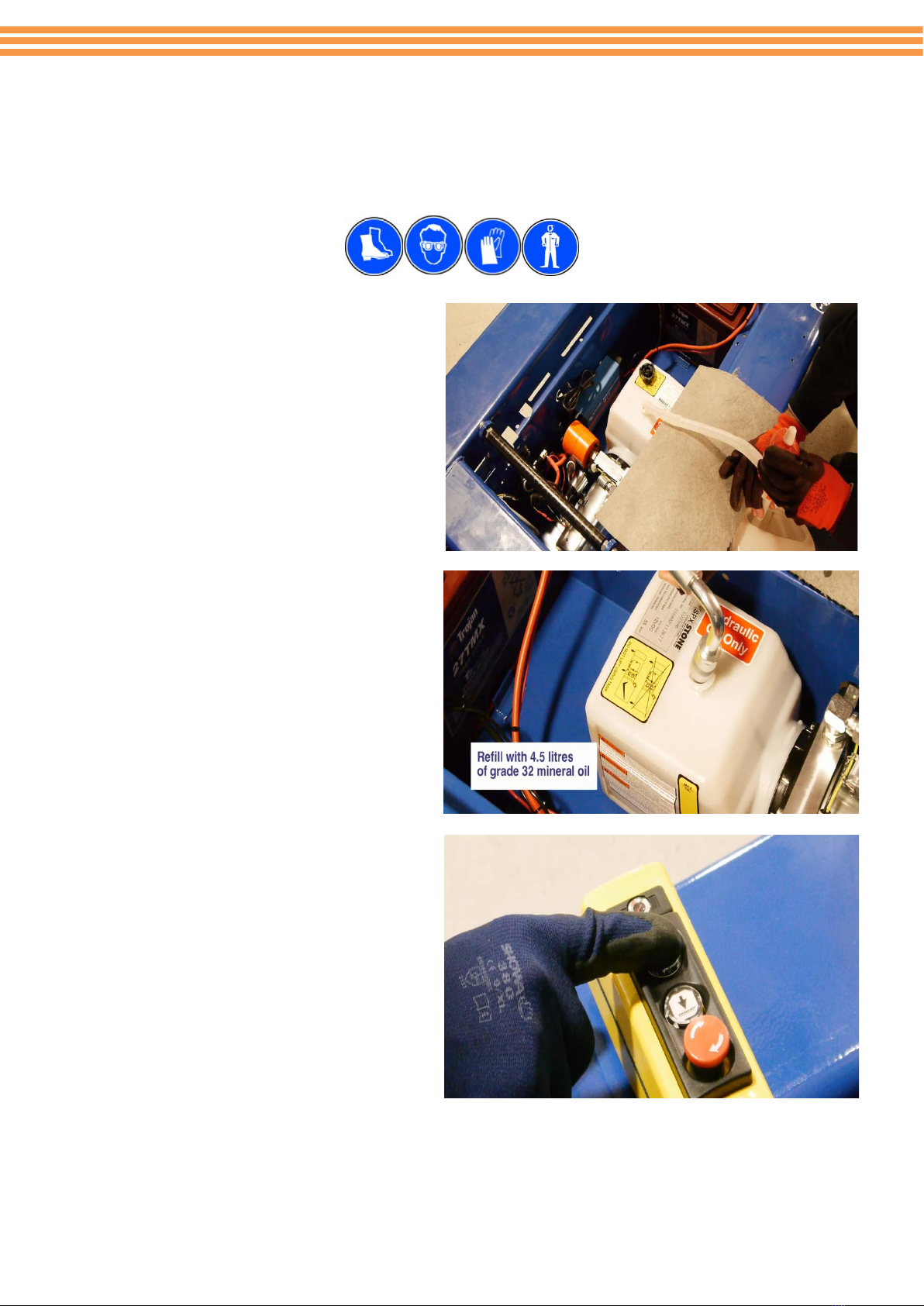

How to Change the Oil in the Hydraulic System

Please ensure,the unit is isolated and you use the correct PPE as indicated.

Use a syringe to empty the hydraulic

reservoir.

Refill with 4.5 litres of grade 32 mineral oil.

Elevate the machine from the Pendant

controls to ensure the platform reaches

full travel. If not add a little more oil.

Do not keep the pump running with no oil

in the tank.

8

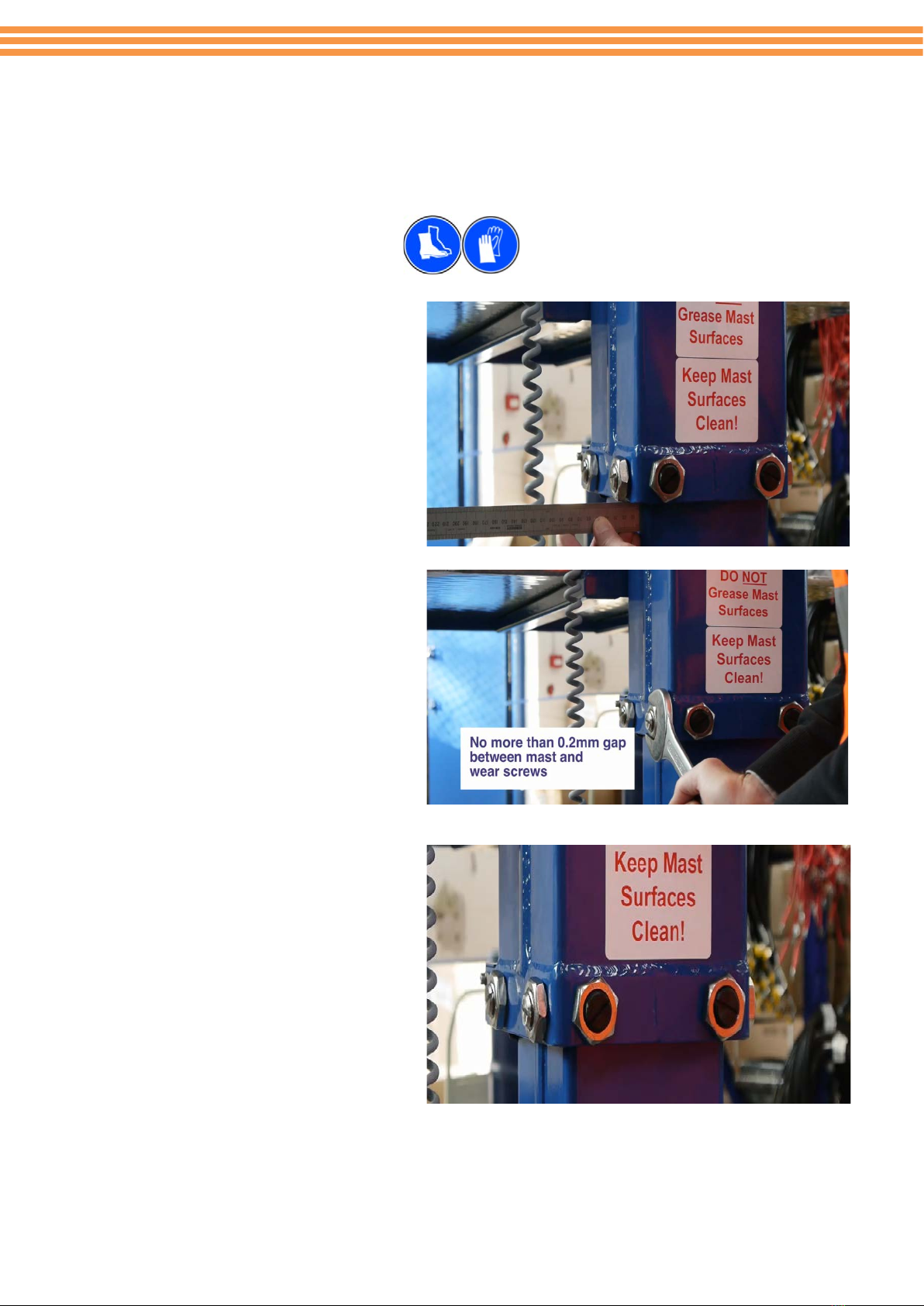

Adjusting the Wear Screws (Mast Section)

Please ensure, the unit is isolated and you use the correct PPE as indicated.

Raise the mast sections using the lift

control to gain comfortable access to

the wear screws. Align the outer

section to the inner section so that the

gap between the inner section and the

outer section is equidistant from side to

side. (18mm)

Screw in the four side wear screws, so

that they just make contact with the

0.2 feeder gauge, slightly back if the

gauge cannot be withdrawn, and

tighten

the

lock nut. Repeat the

process for the middle mast section to

lower the

mast.

Adjust the two rear plastic wear screws

in a similar manner. It is not possible to

adjust the clearance between the inner

and outer sections with the rear screws.

Remove. Operate the lift function to

ensure the outer and middle sections

do not bind. Back off slightly any wear

screws found to be pinching so that

both mast sections travel up and down

freely.

9

Castor and Wheel Maintenance

Please ensure, the unit is isolated and you use the correct PPE as indicated.

Ensure the Castor bolt is torque to

55Nm, If the castor bolts are to be found

to be worn then replace with PT-M-170.

Again ensure this is tightened and

torqued to 55Nm.

Ensure the wheel spins freely and

rotates on the castor if the wheel

doesn’t move freely after being

tightened to the required torque then fit

a spacer washer. Check for any damage,

the breaking latch moves freely and the

castor is not twisted.

10

Replacement of Castor Wheel

Please ensure, the unit is isolated and you use the correct PPE as indicated.

Raise the machine from the ground with

a suitable hoist or block the front of the

machine so the castor wheels are clear of

the ground by approximately 50

millimetres. Undo the fixing bolt and

remove the castor.

Refitting is a reverse of this procedure

but it is essential to fit a spacer washer

but when tightening the fixing bolt,

ensure it is torque to 55Nm, ensure the

wheel moves freely.

11

Gate Latch Adjustment

Please ensure, the unit is isolated and you use the correct PPE as indicated.

Offer the gate to the hinges and pass

the long pivot bolt downward through

the top hinge bracket. When feeding

downward, slide the bolt though the

spring until just before passing through

the lower hinge bracket. Twist the

lower arm of the spring behind the

gate upright and then pass the pivot

bolt through the lower hinge.

Allow the gate to close, and check that

the “U” pin locates correctly in the jaw

of the of the gate latch. If the “U” pin is

too low, raise the pivot bolt slightly

above the lower hinge and fit one or

two M10 washers as required. Pass

the pivot bolt all the way through the

hinge plates, fit and tighten a lock nut

and washer

12

Removing or Replacing the Hydraulic Pipe

Please ensure, the unit is isolated and you use the correct PPE as indicated.

Lower the platform to the transport

position, raise the cage and lock the gas

strut. Open the manual emergency

lowering valve and allow the oil to drain to

the tank for a minute or two.

Direction of twist is indicated by the red

arrow.

Remove the spine end cap and then

disconnect the hydraulic connection to the

cylinder

Move to the top of the power pack and

remove the chassis cover. Identify the

steel pipe connection and undo the

fittings. There may be a very small amount

of oil loss at this time. The pipe now can

be withdrawn.

13

The new pipe is refitted in the reverse

sequence. Ensure to connect both ends

of the pipe loosely to ensure correct

alignment and then tighten the cylinder

connection first, taking care not to twist

the pipe. It may be necessary to slacken

the two power pack mounting screws

located under the middle of the power

pack to enable correct alignment.

When replacing the power pack mounting screws

ensure to apply a small amount of Loctite 648

14

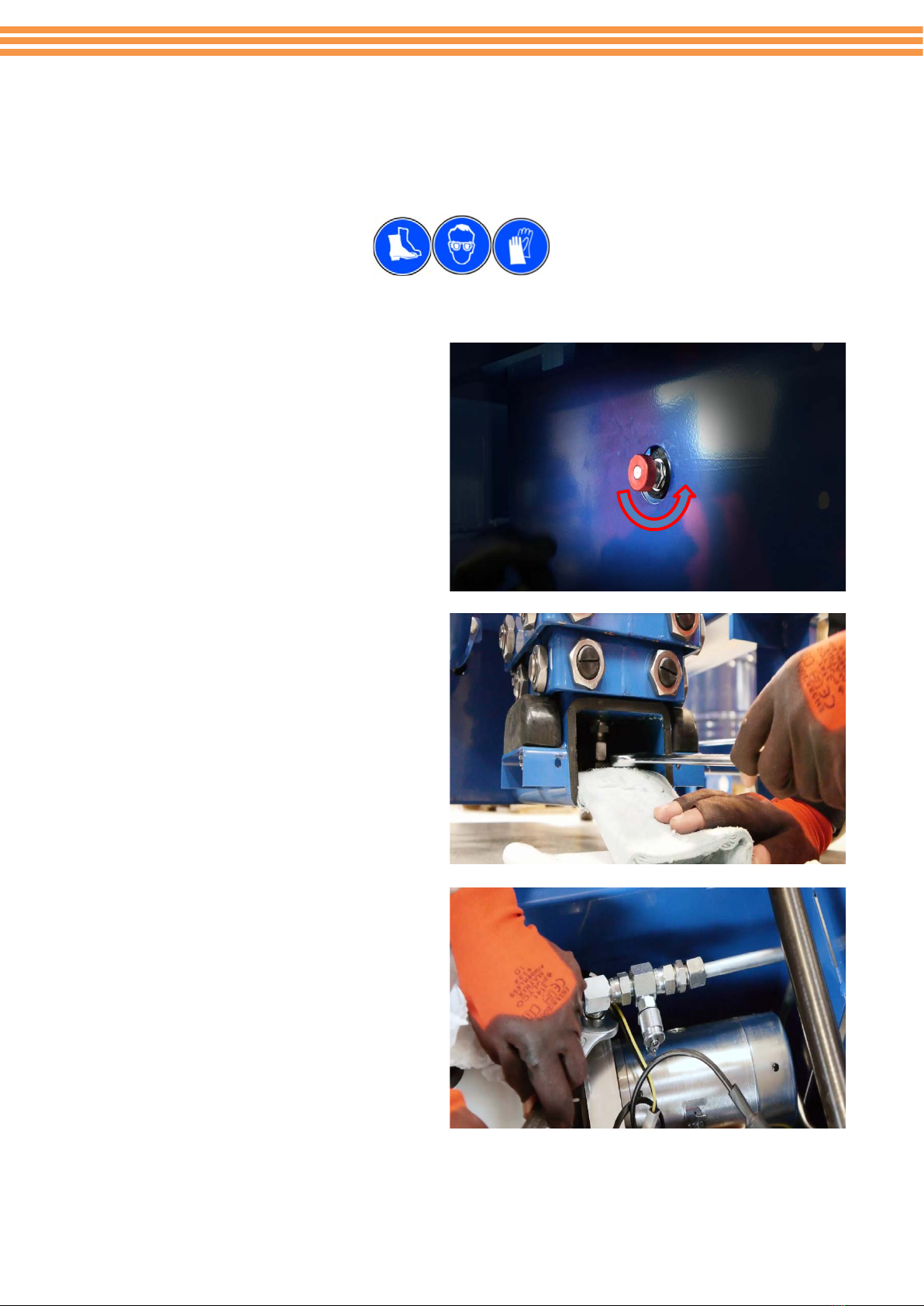

Remove or Replace the Emergency Lowering Valve

Please ensure, the unit is isolated and you use the correct PPE as indicated.

Fully lower the platform and open the

emergency-lowering valve for a minute or

two, to fully drain the oil. To open the

emergency lowering valve push the milled

knobs in and slightly turn anticlockwise.

Direction of twist is indicated by the red

arrow.

Raise the platform and lock the gas strut.

Either lift the machine on a suitable hoist

or raise the base of the machine on the

emergency lowering valve side and chock

up in a safe manner.

Place some oil soak cloths around the

power pack pipe connection and undo the

pipe connection. Locate the spine cap and

remove, loosen the pipe, there may be a

small amount of oil spillage. Locate the

two power pack fixing screws, located

under the base of the machine, below the

centre of the power pack and undo

15

Move the power pack sideways to gain full

access to the lowering valve. Remove the

knurled knob and solenoid, and then the

valve cartridge

Refit the new or repaired valve cartridge

and reassemble using the reverse

sequence. Set the knurled knob in the

normally closed locked position to close

the emergency lowering valve push in and

slightly turn clockwise, check that the

machine elevates, and remains stationary

when elevated, when the machine is back

on the ground in a stable condition.

16

Removing or Replacing the Lift Cylinder

Please ensure, the unit is isolated and you use the correct PPE as indicated.

Open the emergency lowering valve and

ensure the platform is fully lowered.

Allow the oil to drain for a minute or

two. To open the emergency lowering

valve push the milled knobs in and

slightly turn anticlockwise.

Direction of twist is indicated by the red

arrow.

Remove the tool tray on top of the mast.

Remove the countersunk screw in the

centre of the mast cap.

17

Undo the four bolts situated around the

mast cap and remove.

Remove the Spine End Cap.

Place suitable oil soak rags on the floor

around the base of the machine at the

rear, Disconnect the hydraulic pipe from

the cylinder, around 0.25 litres of oil

may be lost. It may be essential to

loosen the pipe on top of the power

pack.

18

With a sling or hoist lift the cylinder

clear of the machine. Reverse the

procedure to refit the cylinder. When

reassembling the mast cap please

ensure to apply a small amount of

Loctite 648 to the locking bolts and

torque to 30 Nm.

19

Removal and Assembly of the Telescopic Mast

Please ensure, the unit is isolated and you use the correct PPE as indicated.

Fully lower the platform and open the

emergency-lowering valve for a minute

or two, to fully drain the oil. To open

the emergency lowering valve push the

milled knobs in and slightly turn

anticlockwise. Display push and turn

anticlockwise.

Tilt the platform upward and support

with a sling or hoist. Remove the gas

strut.

Lower the cage and undo the two main

fixing bolts. With the sling or hoist,

remove the complete cage.

20

Remove the tool tray on top of the

mast. Remove the countersunk screw

in the centre of the mast cap. Undo

the four bolts surrounding the mast cap

and remove.

With the hoist, raise the mast outer

section a short distance to a convenient

position and remove the roller and

wear screws. When removed lift the

mast section clear of the mast using the

hoist taking care to clear the inner stop

blocks as the mast is raised.

Repeat the process for the mast middle

section. Access can now be gained for

any maintenance or remedial work

required. Reverse the procedure to

reassemble the mast and platform.

When reassembling the mast cap

please ensure to apply a small amount

of Loctite 648 to the locking bolts and

torque to 30 Nm

Table of contents

Other Power Towers Lifting System manuals

Popular Lifting System manuals by other brands

DINGLI

DINGLI AMWP8-1200 operators manual with maintenance information

AussieCarHoists

AussieCarHoists YL5000 user manual

Braun

Braun NVL Vista 02 Series Service manual

LSP inc.

LSP inc. LSC1576 owner's manual

STARKE ARVID

STARKE ARVID Vakuflex 280 operating instructions

Sportsman

Sportsman ALBLFT Assembly instructions