Page 7SKU 97816 For technical questions, please call 1-800-444-3353.

Turn off the Table Saw and allow the26.

Saw Blade to completely stop if the

Saw Blade is to be backed out of an

uncompleted cut.

Never attempt to remove material27.

stuck in the moving parts of the Table

Saw while it is plugged in and run-

ning.

Make sure the woodstock to be cut off28.

has sufcient room to move side-

ways. Failure to do so may result in

off-cut binding against the Saw Blade.

Always unplug the Table Saw from29.

its electrical outlet before performing

inspection, maintenance, cleaning

procedures, or changing accessories.

Before trying new or complicated30.

techniques, study the procedure, and

practice with scrap wood.

Make sure the woodstock is free from31.

loose knots, aws, nails, and any

other foreign objects that could dam-

age the Saw Blade or cause “kick-

back”.

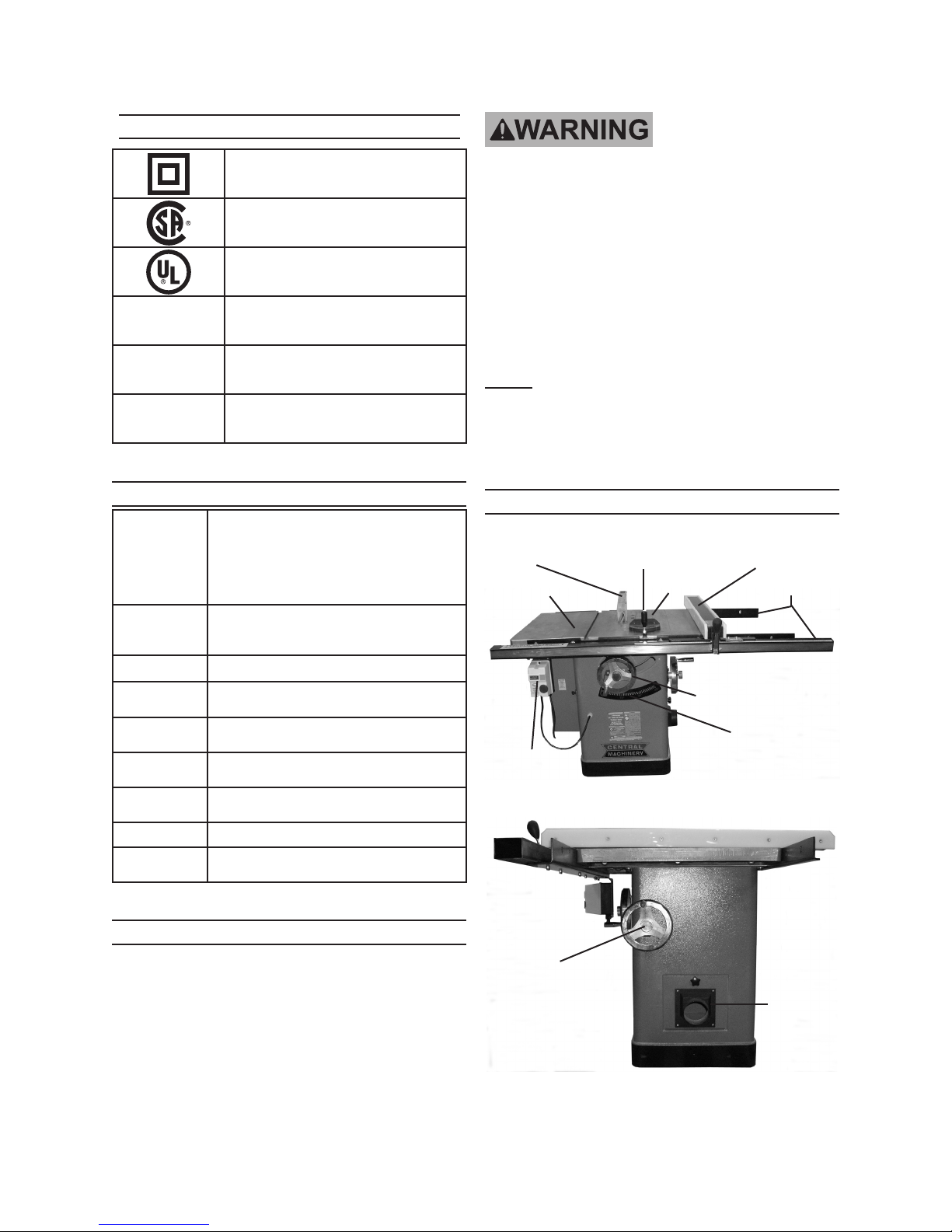

Causes and operator prevention of32.

“kickback”: Kickback is a sudden

reaction to a pinched, bound, or mis-

aligned Saw Blade, causing an un-

controlled woodstock to lift up and out

from the Table Saw toward the opera-

tor. When the Saw Blade is pinched

or bound tightly by the kerf closing

down, the Saw Blade stalls and the

motor reaction drives the woodstock

rapidly back toward the operator. If

the Saw Blade becomes twisted or

misaligned in the cut, the teeth at

the back edge of the Saw Blade can

raise the woodstock (walk up), and

eject it toward the operator. Kickback

is a result of tool misuse and/or incor-

rect operating procedures or condi-

tions and can be avoided by taking

proper precautions as given below:

Maintain control of the woodstock at•

all times. Never allow the woodstock

to rest on the moving Saw Blade

without holding on to the woodstock.

When the Saw Blade is binding,•

or when interrupting a cut for any

reason, turn off the Power Switch

and hold the woodstock motionless

on the Table saw until the Saw Blade

comes to a complete stop. Never at-

tempt to remove the woodstock from

the Table Saw or pull the woodstock

backward while the Saw Blade is in

motion or kickback may occur. In-

vestigate and take corrective actions

to eliminate the cause of Saw Blade

binding.

When restarting a woodstock on the•

Table Saw, center the Saw Blade

in the pre-cut kerf and check that

the Saw Teeth are not engaged into

the woodstock. If the Saw Blade is

binding, the woodstock may walk

up or kickback as the Table Saw is

restarted.

Support large panels with roller•

stands (not included) to minimize

the risk of Saw Blade pinching and

kickback. Large panels tend to sag

under their own weight. Supports

must be placed under the panel and

near the outer edge of the panel.

Do not use a dull or damaged Saw•

Blade. Unsharpened or improperly

set Saw Blades produce a narrow

kerf causing excessive friction, Saw

Blade binding and kickback.

Never use the Fence assembly as a•

guide when crosscutting.