Page 5 SKU # 95647

5. OncetheStandsare positioned properlyona solidlevelfloor,place the Lathe’soilpan on them.

Alignthemountingholesintheoilpanwiththeholes inthe Stands.Ifneeded,placeshims(notin

cludedbetween the oil/chiptrayand theLatheStands. Checkthelevel andpositionof theStands

againto besurethat whentheLathe ispositionedon thestandsand chiptrayit willbe level,solidand

alignedwiththemountingholes intheStandsandtray.

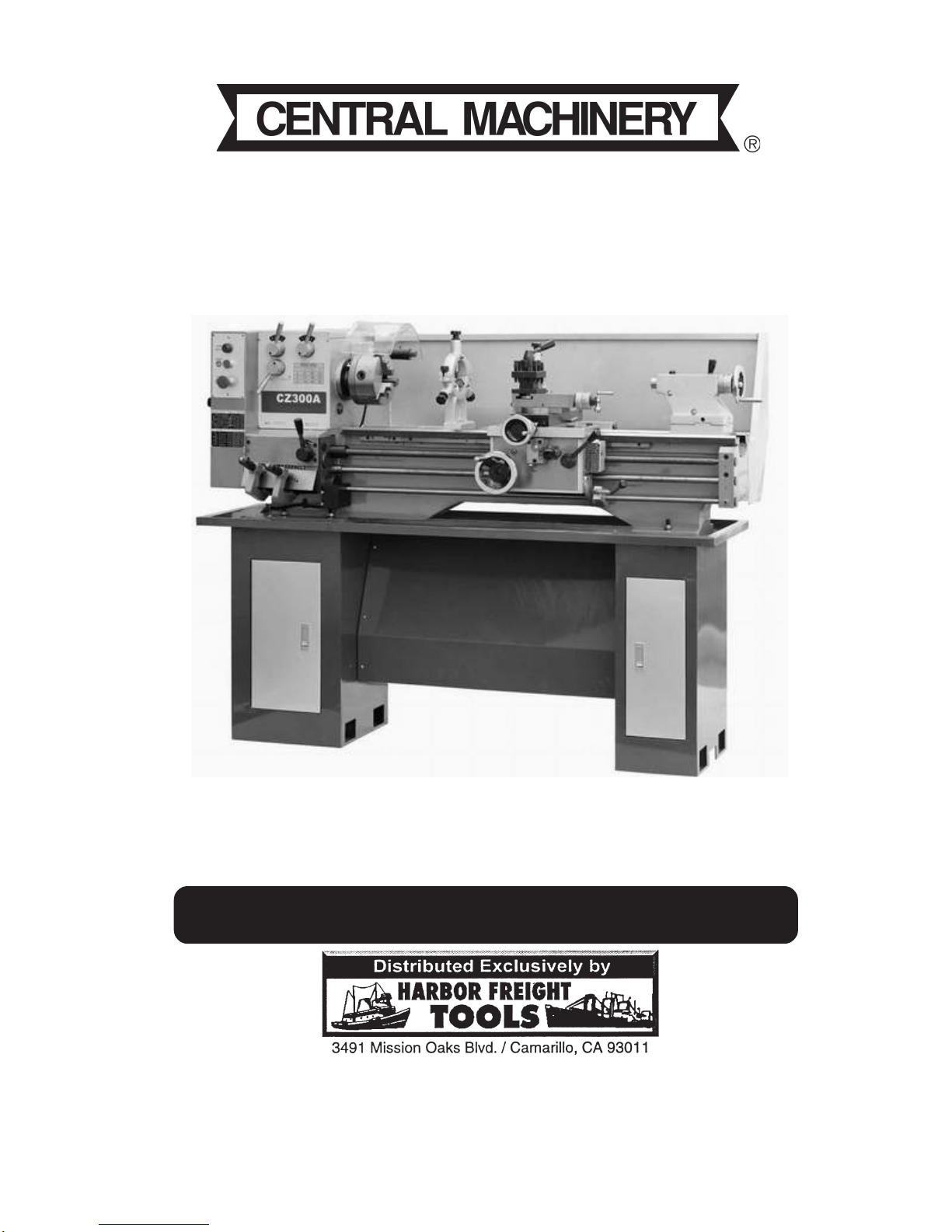

HOISTINGANDLEVELINGLATHE ONTOSTAND

WARNING:DONOTATTEMPTTOLIFTTHELATHEBYYOURSELF.

The 43681 Lathe weighs over 800 Lbs., and cannot be lifted safely by one or several strong men.

Be sure the Lathe is balanced on the hoist or lift you will use to move it before moving the Lathe.

1. Beforehoisting,lifting ormovingtheLathe,movethetailstock andaprontothefarright

endof the bedway(away from theheadstock) andlockthem inplacethere. Thiswillhelp to

balancethe overallmassofthemachine nearthe center.

2. Use pads(notincluded) toprotectthe machinefromdamage bythe equipmentusedto hoistit.

3. Use ahydrauliclift, forklift,or hoisttoposition theLatheonto theStand.Read andadhereto all

safetywarningsandinstructionsprovidedbythemanufactureroftheliftingdevicethat isbeingused.

4. When thelatheispositionedontheoil trayand Stand,align themountingholesanddropinthe

mountingbolts.

5. Check thelevelof themachine.Using aspiritlevel, check tobe sure thatthebed ofthelathe

islevel bothhorizontallyand frontto back.Ifthere isany outoflevel, correctit now.

Dependingonyourinstallation,useangledironlevelers(shims)toadjustthemachine intoexact

levelfrontto back andsideto side. Checkbothends of thetoolbefore being satisfied.

Besurethemachineislevel,positionedsolidly,andisresistanttovibration.

6. Fasten thelatheto theStandandthe Lathe’soiltray byinsertinga bolt througha lock washerfrom the

insideofthe Stand andupwardthrough theoiltray andlathe.Fasten with awasher and nut.

Repeat thisforeachofthefourmountingholesintheheadstock, andboth mountingholesin

thetailstock.Tightensecurely.Recheckandreadjustlevelifrequired.

NOTE: Periodically recheck the level of the machine to assure that it remains level while it is in use.