Page 8SKU 96100 For technical questions, please call 1-800-444-3353.

INSPECTION, MAINTENANCE, AND CLEANING

WARNING!1. Make sure the air supply hose and water hose are disconnected from

the Angle Grinder before performing any inspection, maintenance, cleaning proce-

dures, or leaving it unattended.

Before each use,2. inspect the general condition of the Air Grinder. Check for loose

screws, misalignment or binding of moving parts (by rotating the wheel manually),

cracked or broken parts, damaged Cutting Wheel, loose air/water fittings, and any

other condition that may affect the safe operation of the Grinder. If abnormal noise

or vibration occurs, have the problem corrected before further use.

Do not use damaged equipment.

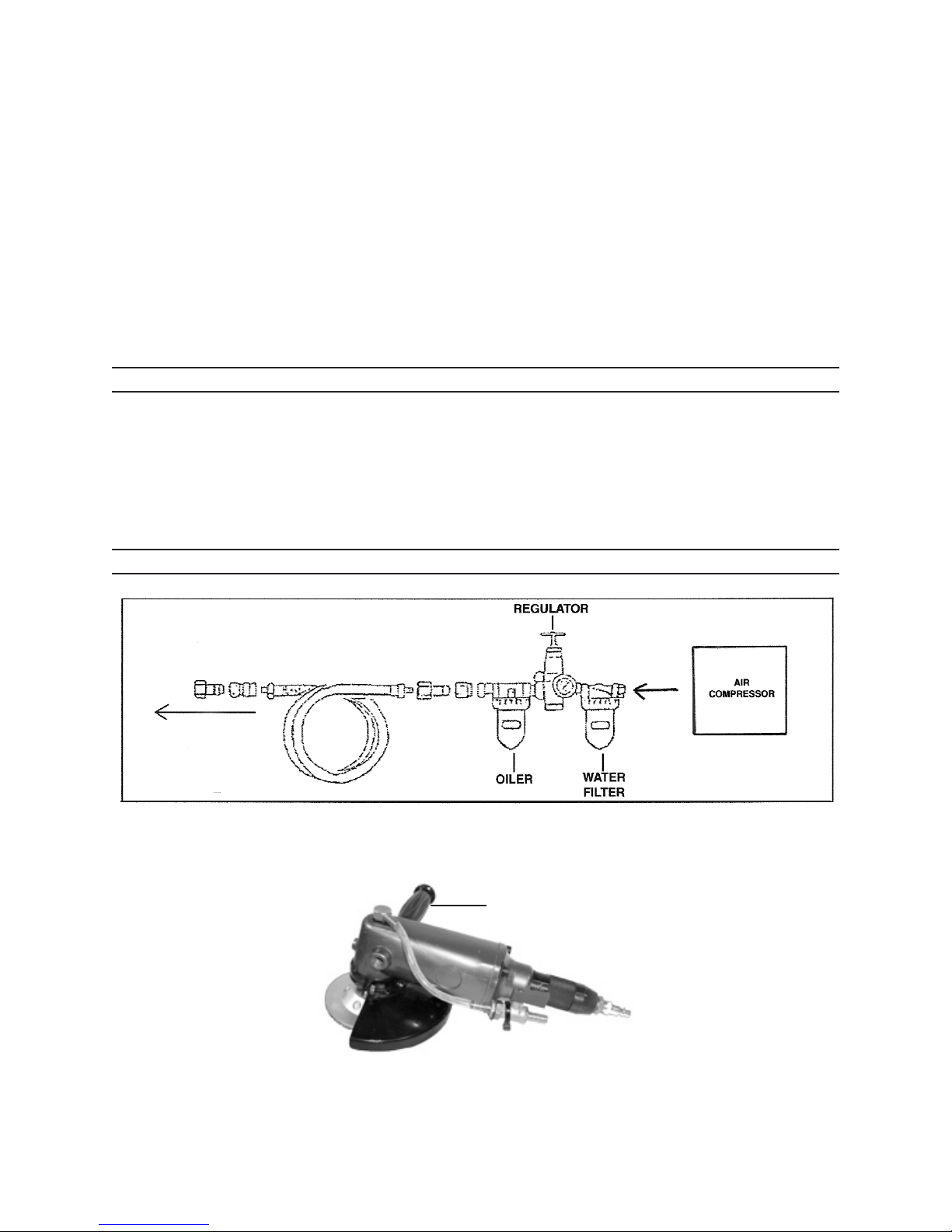

Before each use,3. rotate the Air Regulator counter clockwise to the shut position.

With the compressor in the off position, and the air supply valve in a closed position,

attach the air hose to the inlet connector. With the water valve in a closed position,

and the water tap closed, attach the water supply hose to the water valve. Open

the water supply to the Grinder, and then open the air supply valve from the com-

pressor. Briefly run the unit. Should you feel any vibration or hear any abnormal

noise, or see any water leakage from the clear water supply tube, abruptly turn the

unit off by disconnecting the air supply hose from the unit, shut the water supply

valve, and disconnect the air and water supply hoses, and have the unit serviced

by a qualified technician.

To clean,4. use a clean cloth and mild detergent. Then, dry. Do not use solvents.

Do not immerse the Angle Grinder in liquid.

CAUTION! All maintenance, service, or repairs not mentioned in this manual5.

must only be performed by a qualified service technician.

TROUBLESHOOTING

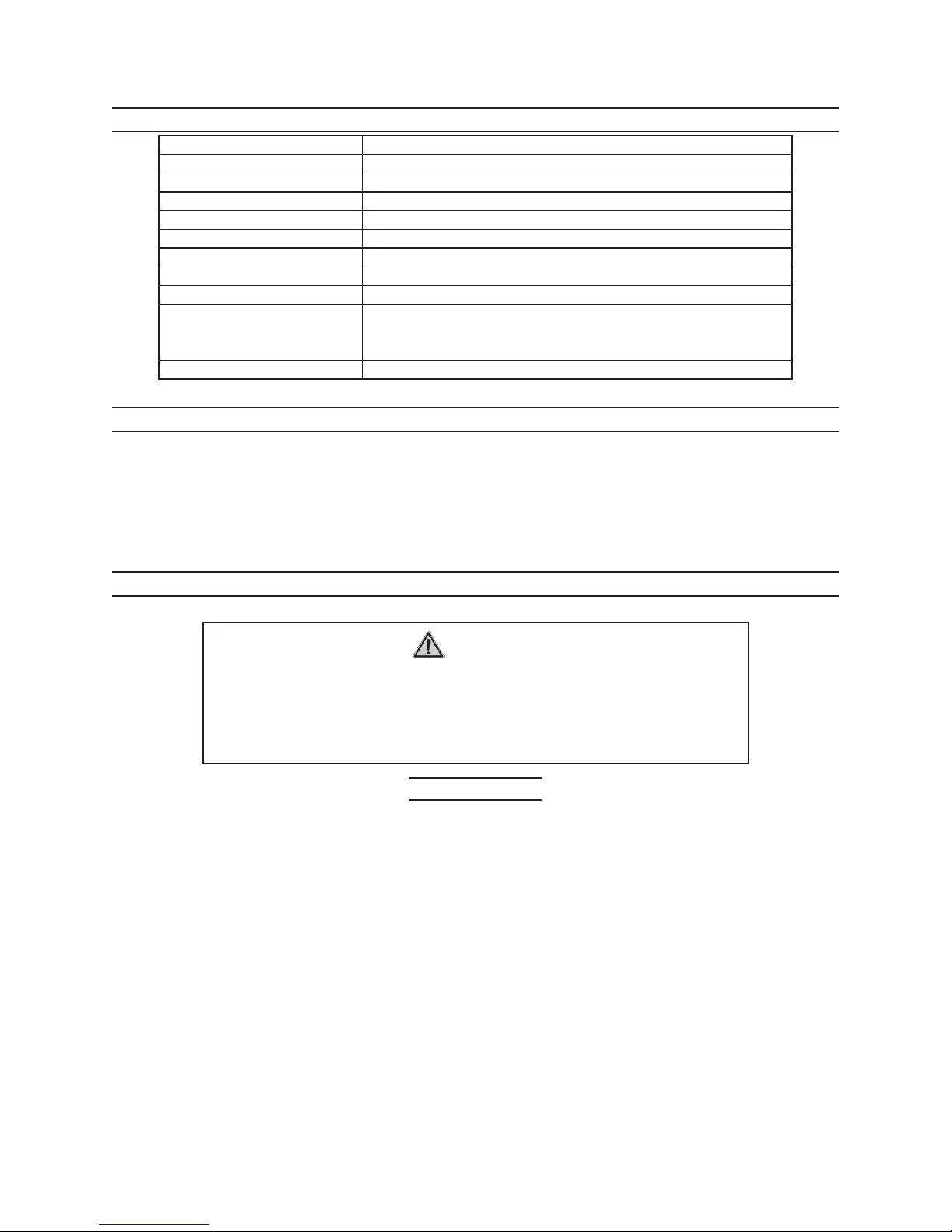

Problem Possible Cause Possible Solution

Tool does not run at normal

speed.

Not enough air supply.1.

Air Regulator closed.2.

Air supply connection loose.3.

Lack of lubrication.4.

Bearings and/or O-Rings worn out.5.

Adjust compressor regulator to 90 PSI.1.

Open Air Regulator.2.

Secure air supply connection.3.

Make sure an in-line oiler is installed in air4.

supply line.

Have a qualified service technician replace5.

Bearings and/or O-Rings.

Automatically starts when

connected to air supply.

Air Regulator open. Close Air Regulator.

Abnormal vibration. Housing

overheats.

Rotor Blades broken or worn out. Have a qualified service technician replace Rotor

Blades.

Poor cutting quality. Dull or defective Cutting Wheel. Replace Cutting Wheel.