Page 3SKU 95028 For technical questions, please call 1-800-444-3353

6. Stay alert. Watch what you are doing and use common sense when operating a

pneumatic tool. Do not use a pneumatic tool while tired or under the inuence

of drugs, alcohol or medication. Doing so may result in serious personal injury.

7. Dress properly. Do not wear loose clothing or jewelry. Contain long hair.

Keep your hair, clothing, and gloves away from moving parts. Loose clothes,

jewelry, or long hair can be caught in moving parts.

8. Avoid accidental starting. Be sure the Trigger Lever (14) is off before connecting

to the air supply. Carrying pneumatic tools with your nger on the Trigger, or

connecting pneumatic tools to the air supply with the Trigger on, invites accidents.

9. Remove adjusting keys or wrenches before turning on the tool. A wrench or a key

that is left attached to a rotating part of the tool may result in personal injury.

10. Do not overreach. Keep proper footing and balance at all times. Proper footing

and balance enables better control and of the toll in unexpected situations.

11. Use safety equipment. Always wear ANSI-approved safety glasses under-

neath a full face shield, and hearing protection.

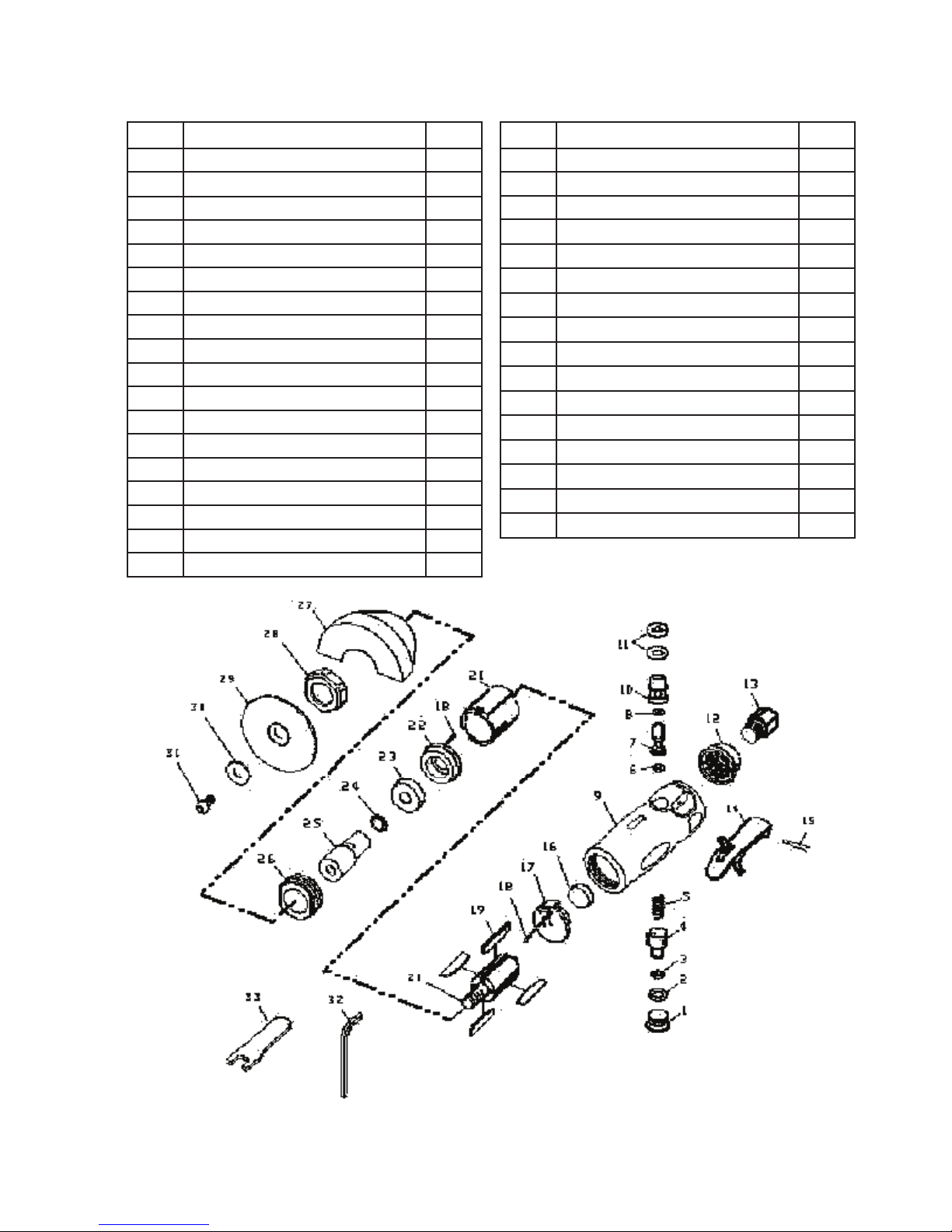

12. Replacement parts and accessories. When servicing, use only identical

replacement parts. Use of any other parts will void the warranty. Only use accessories

intended for use with this tool. Approved accessories are available from Harbor

Freight Tools.

13. Do not operate tool if under the inuence of alcohol or drugs. Read warning

labels if taking prescription medicine to determine if your judgement or reexes are

impaired while taking drugs. If there is any doubt, do not operate the Cut-Off Tool.

14. Use proper size and type extension cord. If an extension cord is required, it

must be of the proper size and type to supply the correct current to the compressor

without heating up. Otherwise, the extension cord could melt and catch re, or cause

electrical damage to the compressor. Check your air compressor’s manual for the

appropriate size cord.

15. Maintenance. For your safety, maintenance should be performed regularly by a

qualied technician.

16. Compressed air only. Use clean, dry regulated, compressed air at 90 PSI. Never

use oxygen, carbon dioxide, combustible gases, or any other bottled gas as a power

source for this tool.

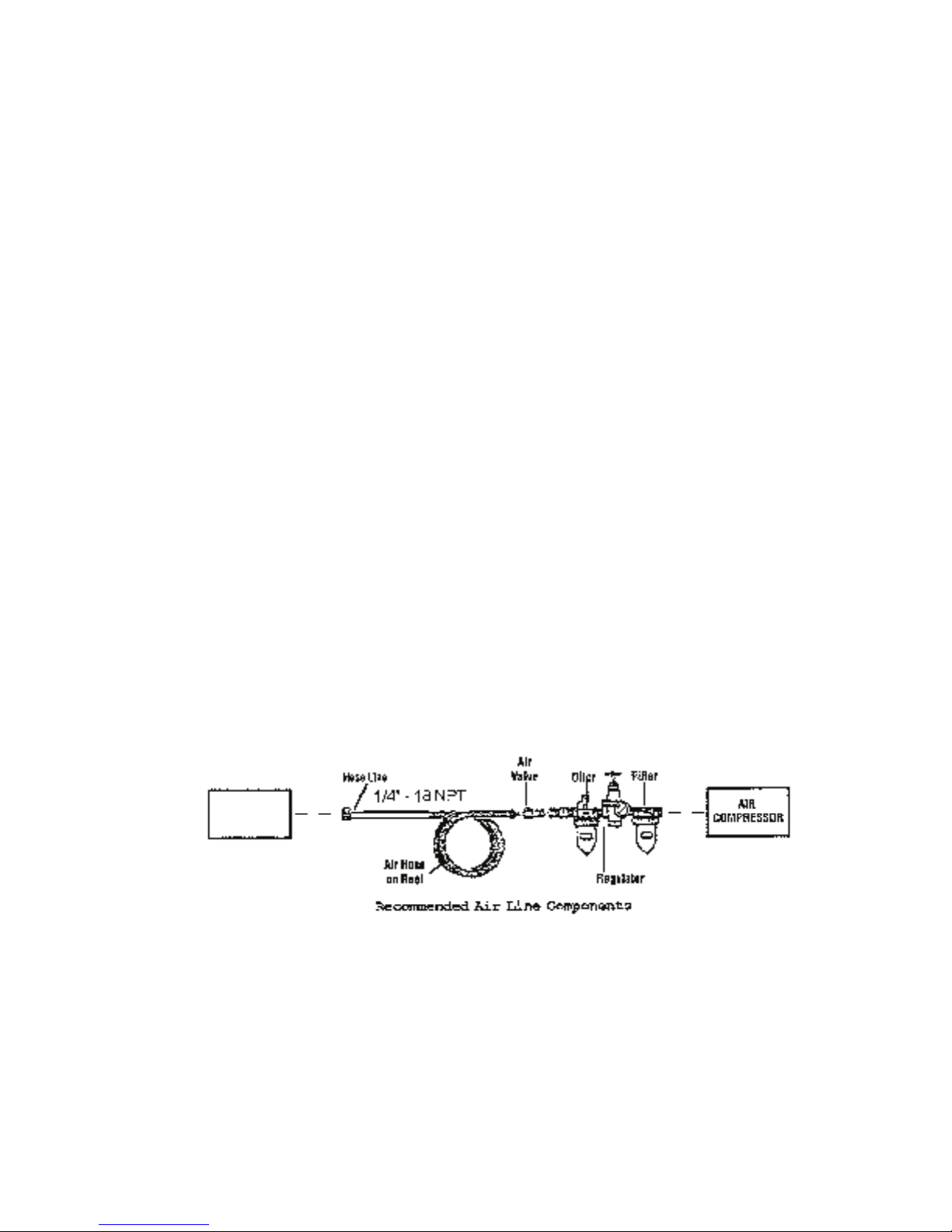

17. When connecting to the air supply: Prior to each use, if an automatic oiler is not

used, add two drops of air tool oil (not included) into the Air Inlet (13) tting of the Cut-

Off Tool.

18. Always disconnect the Cut-Off Tool from its compressed air supply source, and

squeeze the Trigger Lever (14) to release all compressed air in the tool before

performing any maintenance or services.

Note: Performance of the compressor (if powered by line voltage) may vary depending

on variations in local line voltage. Extension cord usage may also affect tool

performance.