160 User Guide Revision 1.2.1

9/12

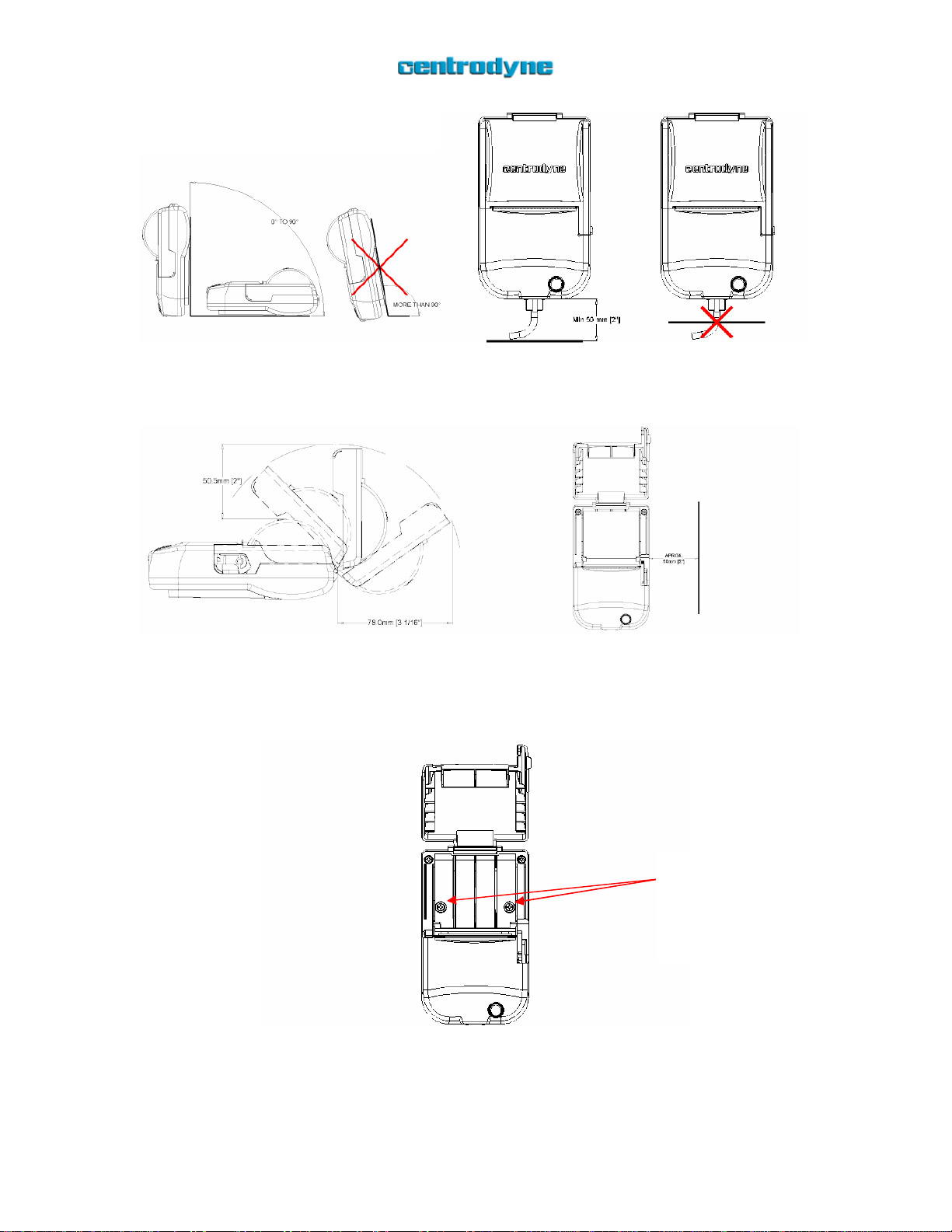

Loading the Paper

NOTE: The 160 printer accommodates paper rolls with the following maximum

dimensions:

- Thickness: 0.08 mm

- Width: 58 mm (approx 2 ¼”)

- Diameter: 48 mm (75-85 feet long)

Using larger/thicker paper roles may damage the printer.

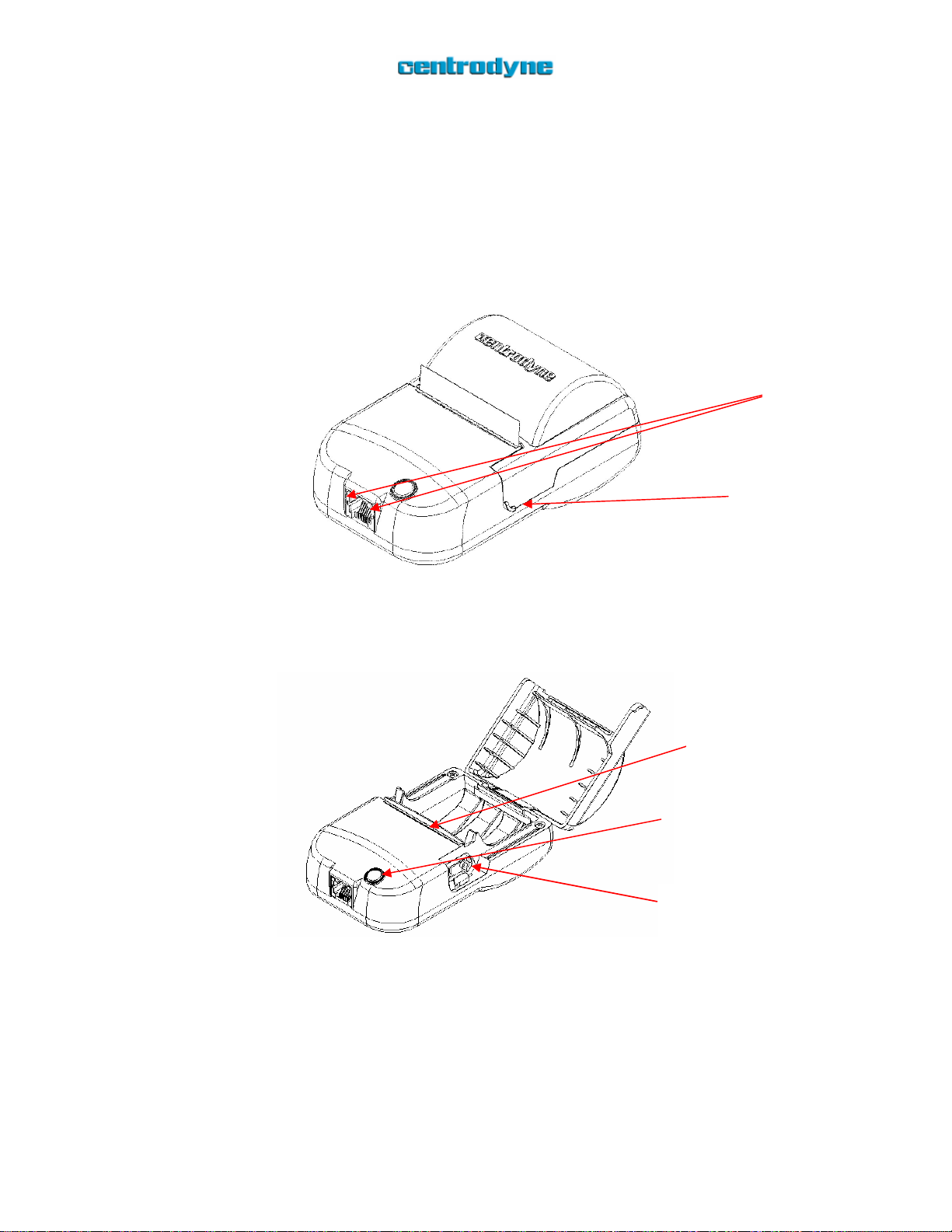

Make sure that the red LED is lit indicating that the printer is powered.

Locate the door release with your right forefinger and lift upwards to open the

printer door.

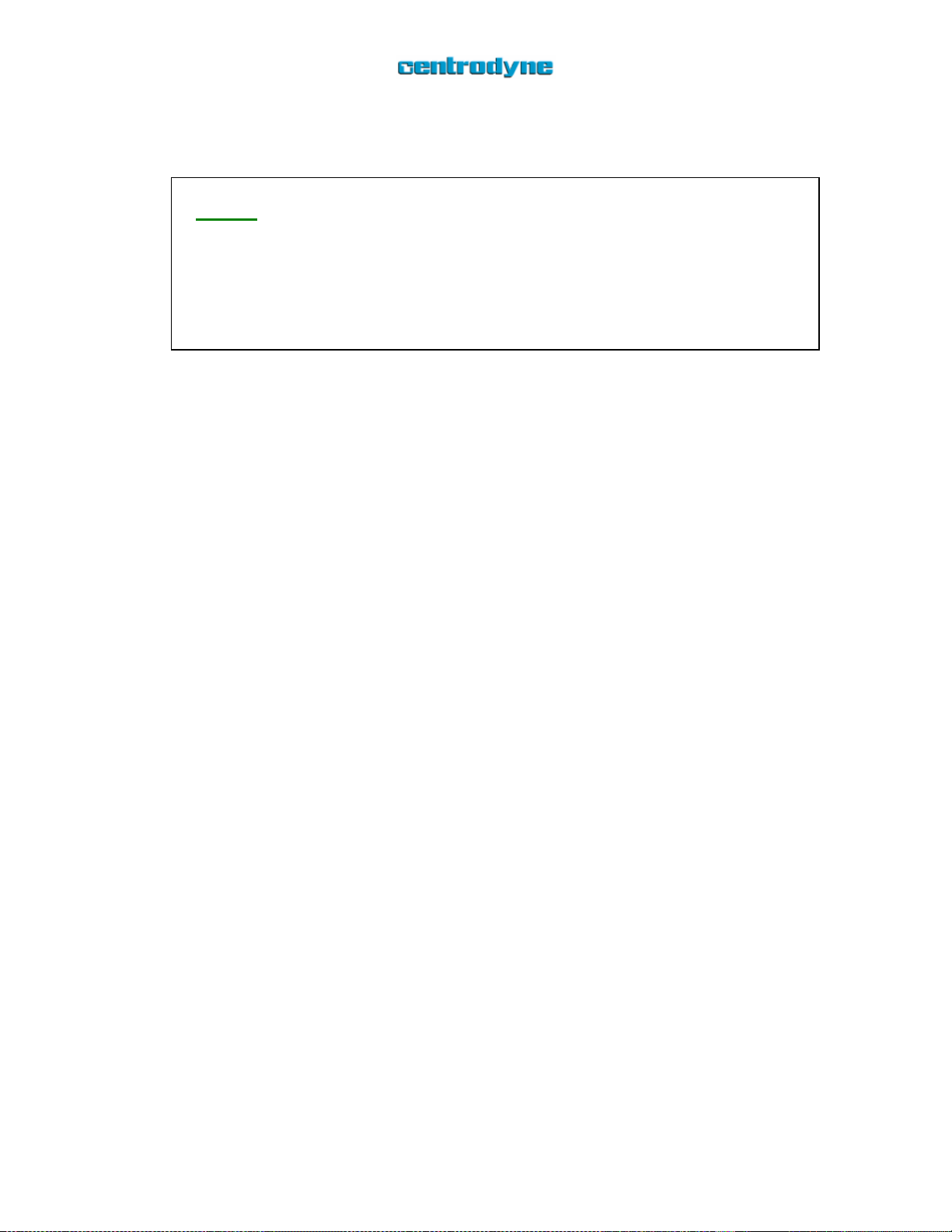

The printer is equipped with a double-action green lever to make paper loading

and clearing jams easier. This lever can sit in 3 different positions: CLOSED,

ADJUST, and OPEN. When the printer door is closed the lever is automatically

forced into the CLOSED position. When loading the paper, make sure that the

lever is in the CLOSED position.

Unroll approximately ½”- ¾” of paper from the end of the roll. Hold the unfurled

portion of paper between your right thumb and forefinger while grasping the

paper roll in the palm of your right-hand.

Insert the unfurled portion of the paper into the slot below the printer platen

(roller bar). Try to ensure that the paper is squared with the printer mechanism as

loading the paper at an angle may cause jamming.

The 160 has an auto paper load feature. Once the unfurled portion of the paper

role has been detected (the sensor is on the same side of the printer mechanism as

the lever) the printer motor will automatically engage for approximately 2

seconds, pulling the paper through.

If the paper is not pulled all the way through you may hold down the paper-feed

button. The printer motor should engage and pull the paper the rest of the way.

If the paper has not been pulled through this means that the printer mechanism

was not able to catch the paper. You need to push the paper further into the slot so

that the printer mechanism can catch it.

Drop the paper roll into the paper roll compartment making sure that there is no

slack or unfurled paper between the paper roll and the printer mechanism.

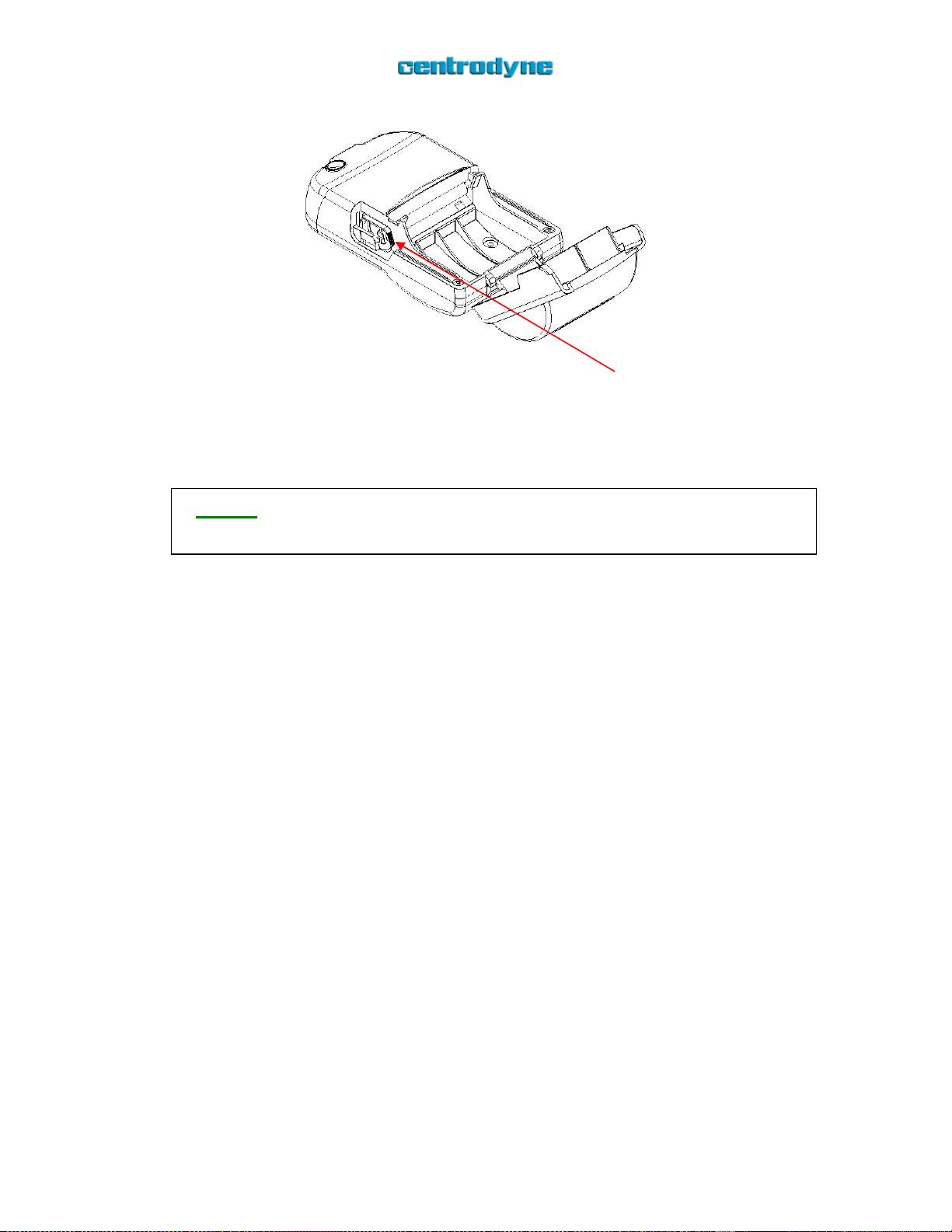

Place the lever into the ADJUST position by pushing back on the serrated edge of

the green lever until you feel it snap into place. (Figure 8)

With your fingers, pull the paper until at least 2 inches of paper is coming out of

the exit slot. With a thumb and forefinger on each side of the 2” paper strip

straighten the paper and make sure that the edges of the paper at the printer exit

are smooth and not bunched up.

Close the printer door! The 160 is now ready to print.