1

SE45010UMC.0306

Important Note

1. Safety Notices:

The machine generates strong high-frequency power when the trigger lever is pulled.

Users should be cautious of potential electric shock during sealing process.

•To avoid potential electric shock, always use the machine with the head protector

mounted on sealing head.

•The machine works even without the head protector mounted on sealing head. If

you should use the machine without the head protector with any reason, never

touch any metal part at sealing head while you are pulling the trigger lever. Finger

may scald instantaneously due to generated high-frequency power if touched at

any metal part in sealing head while the trigger lever is being pulled.

2. Installation and Cautions:

•Primary power requirement for the machine is marked on the rear panel. The

power outlet and the power cord should be grounded ones. Refer to Section 5-2

for proper fuse rating.

•Always keep the sealing head area clean and dry. If the sealing head becomes wet

or dirty, an arc may appear during the sealing process. If an arc appears, clean the

sealing head and let it dry thoroughly. (Refer to Sections 5-1 and 5-3.)

•Use a soft cloth and mild detergent to clean the equipment. After cleaning, wait a

few minutes until the area cleaned is completely dry. DO NO'T USE PAINT

THINNER, BENZENE, SOLVENT OR STRONG DETERGENT.

•Be sure to turn the power switch off before cleaning the machine.

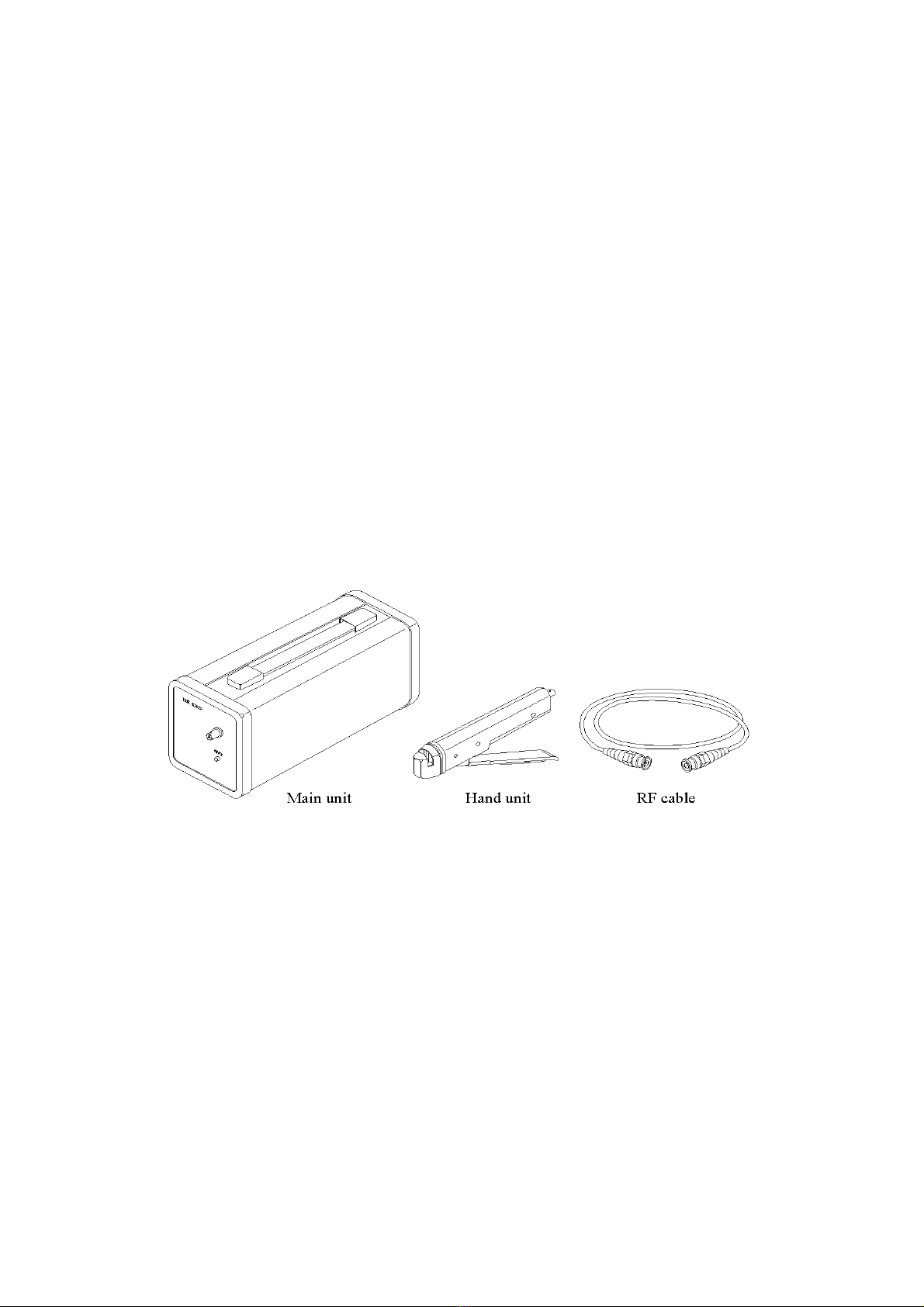

•Only authorized service personnel should remove the covers of the main unit and

the hand unit.

•Avoid pulling the trigger lever without tubing loaded in sealing head as it may mar

the sealing head.

•Never put sharp objects or metal objects in sealing head as damage can occur.

•Avoid using or leaving the machine in a location where the temperature is higher

than 50 °C (122 °F). Keep it away from any heating source or direct sunlight.