1 - 4

1-3. Specification

(1) System configuration : control unit, segmentation unit, inter-unit cable

(2) Operation modes : local, remote switch, remote circuit, remote command

(3) Operation frequency : 40.68 MHz

(4) Overall sealing time : 1 - 3 seconds

(5) Available tubing size : 2 - 6 millimeters in diameter

(6) AC mains voltage

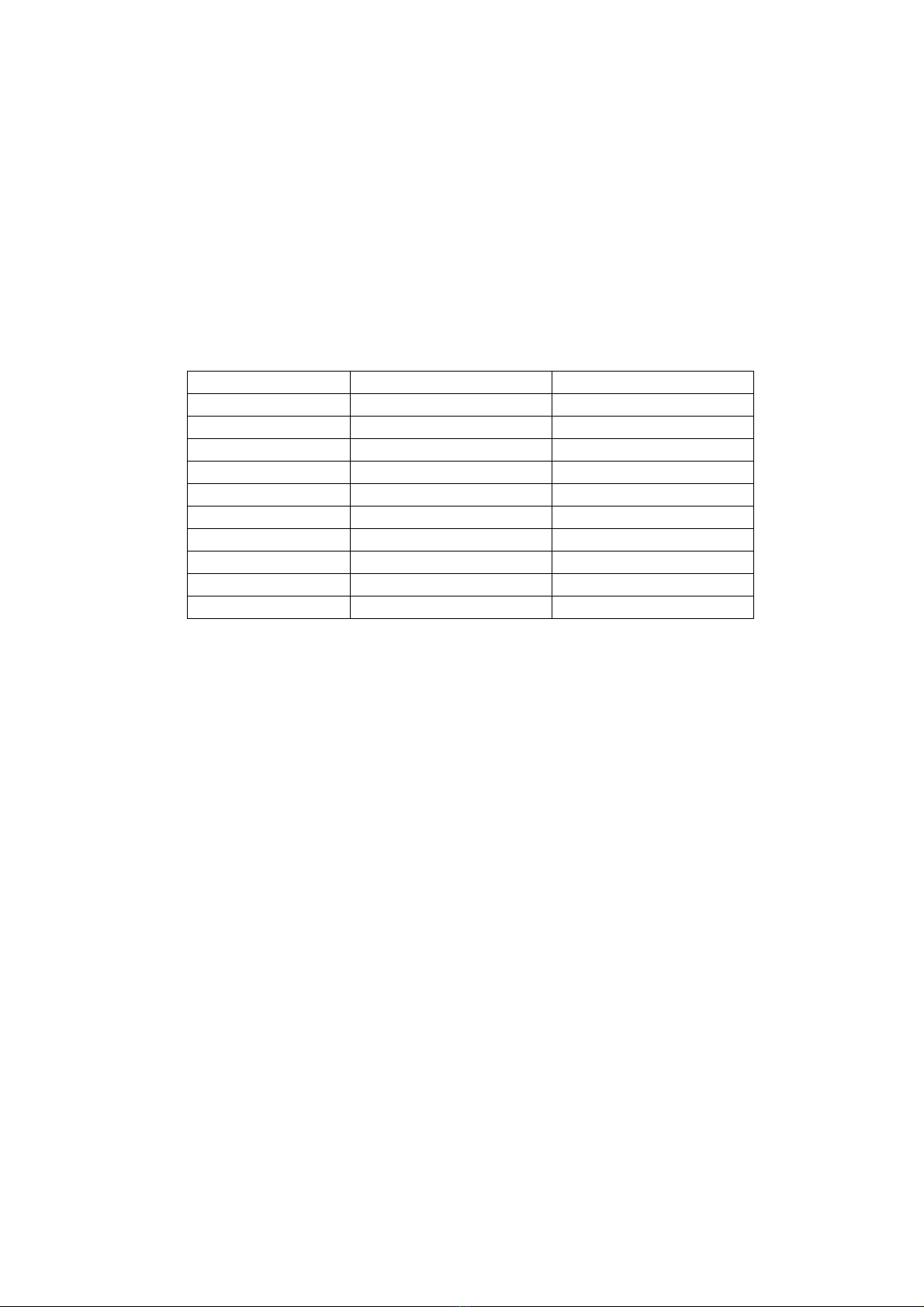

Model MS930A MS940A MS950A MS960A MS970A

Nominal voltage 100-120 VAC, 50/60 Hz, single phase

Working voltage 90-132 VAC, 47-63 Hz, single phase

Power consumption 600 W 800 W 1000 W 1200 W 1400 W

Current rating 6 A 8 A 10 A 12 A 14 A

Model MS930E MS940E MS950E MS960E MS970E

Nominal voltage 200-240 VAC, 50/60 Hz, single phase

Working voltage 180-262 VAC, 47-63 Hz, single phase

Power consumption 600 W 800 W 1000 W 1200 W 1400 W

Current rating 3 A 4 A 5 A 6 A 7 A

(7) Over-current protection : By recoverable circuit breaker

(8) Indication lamps

- Control unit : POWER ON (green)

- Segmentation unit : READY (green), SEALING (red)

(9) Alarms : audible indication by buzzer, visual indication by lamps

(10) Dimension and weight

Model MS930A/E MS940A/E MS950A/E MS960A/E MS970A/E

Control unit

- Size, W-H-D [mm]

- Weight [Kg]

406-200-310

9.5

518-200-310

10.5

630-200-310

11.5

742-200-310

12.5

854-200-310

13.5

Segmentation unit

- Number of head

- Size, W-H-D [mm]

- Weight [Kg]

- Set distance [mm]

3

255-155-210

7.5

75,80,85,90

4

345-155-210

9.0

75,80,85,90

5

435-155-210

10.5

75,80,85,90

6

525-155-210

12.0

75,80,85,90

7

615-155-210

13.5

75,80,85,90

(11) Inter-unit cable

- RF Cable : RG-58, 1.8 meters (6 feet) long, BNC-male at both ends

- Data Cable : 1.8 meters long, 37-pin D-Sub connectors at both ends

(12) Communication parameters

- Baud rate: 19200 bps - Data bits: 8 - Stop bits: 1

- Parity: None - Flow control: None

(13) Temperature characteristics

- Operating :

0 °~ 40 °C (

32 °~ 104 °F)

- Storage : - 20 °~ 70 °C ( - 4 °~ 158 °F)