Centronics H80 User manual

..

I

I

MODEL H80, H136

· · SERVICE MANUAL

REV.

A MAY 1884

THE INFORMATION CONTAINED HEREIN IS

PROPRIETARY AND IS NOT

TO

BE

RELEASED

OR

REPRODUCED WITHOUT WRITTEN PERMIS-

SION OF CENTRONICS DATA COMPUTER CORP.

SERVICING INFORMATION FOR YOUR PRINTER MAY

BE

OBTAINED

BY

CALLING THE NUMBERS LISTED BELOW.

(ASK FOR FIELD ENGINEERING)

'

i

1

'-._._

CEnTRDnlC:S®

data computer corporation

Hudson, New Hampshire 03051

Tel. (603) 883-0111, TWX. (710) 228-6565, TLX. 94-3404

Field Engineering Headquarters (603) 883-2492

Regional Sales Offices

Eastern Region (Mass.):

Central Region (Texas):

Western Region (Calif.):

Tel.

(617)

935-6150,

TWX.

710-348-0343

Tel.

(617)

461-5711,

TWX.

910-890-4916

Tel.

(714)

979-6650,

TWX.

910-595-1925

Regional Field Engineering Offices

Eastern Region (Mass.): Tel.

(617)

935-8130

Central Region (Texas): Tel.

(617)

461-7121

Western Region (Calif.): Tel.

(714)

957-1510

Centronics Data Computer (Canada) Ltd.

Mississauga, Ontario

Tel.

(416)

625-0770,

TWX.

610-492-4382

Centronics Data Computer

(U.K.)

Ltd.

London, England

Tel. 011-44-464-5011, TLX.

851-877801

Centronics Data Computer (France)

71-73

Rue

Desnouettes, 75015 Paris, France

Tel. 828-4051, TLX. 202686

Centronics Data Computer (Germany), Gmbh

6000 Frankfurt am Main

71

Tel. 666-1021, TLX. 841-413224

Centronics

of

Puerto Rico

Dorado, Puerto Rico

Tel.

(809)

796-1881, TLX. 385-9349

Centronics (Italia) S.P.A.

Via Santa Valeria

5,

201123 Milan, Italy

Tel. 809-514

9/80

Rev.

C

© Copyright 1980 Centronics Data Computer Corp.

All rights reserved

Patents pending in U.S.A. and other countries

Printed in U.S.A.

Specifications subject

to

change without notice

MODEL H80, H136

SERVICE MANUAL

37401800-IAOO

REV.A

MAY 1984

SERVICE MANUAL

1800·9AOO

TABLE

OF

CONTENTS

SECTION

1-INTERFACE

Br

SPECIFICATIONS

1.1

COVERAGE

OF

THIS

MANUAL

...............................................

1·1

1.2

OVERVIEW

..........................•....................................

1·1

1.3

SPECIFICATIONS;

HBO,

H136

................................................

1·2

1.4

INTERFACE

SPECIFICATIONS

.....................................•..........

1·5

SECTION

2-THEORY

OF

OPERATION

2.1

GENERAL

..........................................................•.....

2·1

2.2

CONTROL

CARD

BLOCK

DIAGRAM

.........................••.................

2·2

2.3

MEMORY

MAP

..........................•.................................

2·3

2.4

INITIALIZATION

ROUTINE

...........•.......................................

2·4

2.5

CONTROL

CARD

CIRCUITS

...................•..............•...............

2·5

2.6

JUMPER

SETTINGS

.......................................................

2-12

2.7

DIP

SWITCH

SETTINGS

....................................•.•.............

2·13

SECTION

3-PREVENTIVE

MAINTENANCE

3.1

DESCRIPTION

.....................................

·

...............•.......

3-1

3.2

CLEANING

...............................................................

3·1

3.3

LUBRICATION

.......................•...................•................

3·1

SECTION

4-REPLACEMENT

PROCEDURES

4.1

PURPOSE

...........................•....................................

4·1

4.2

PRINT

HEAD

REPLACEMENT

(Refer

ta

Users

Manual)

............................

4·1

4.3

REMOVAL

OF

COVERS

...................................•.••..............

4·1

4.4

PRINT

MECHANISM

REMOVAL

...............................................

4-4

4.5

CONTROL

CARD

REMOVAL

..................................................

4-5

4.6

POWER

SUPPLY

REMOVAL

..................................................

4-6

4.

7

PLATEN

REMOVAL

...................•.....................•..............

4-7

.

4.B

HBO

TRACTOR

REMOVAL

...................................................

4-8

4.9

H136

TRACTOR

REMOVAL

..................................................

4·9

4.10

HBO

CARRIAGE

TIMING

BELT

REMOVAL.

.....................................

4-10

4.11

H136

CARRIAGE

TIMING

BELT

REMOVAL

...........................•.........

4·11

4.12

PAPER

RETAINER

Bi

CARRIAGE

GUIDE

SHAFT

REMOVAL.

.........•..............

4-12

4.13

PINCH

ROLLER

REMOVAL

.................................................

4·13

4.14

CARRIAGE

DRIVE

MOTOR

REMOVAL

.........................................

4-14

4.15

PAPER

FEED

DRIVE

MOTOR

REMOVAL

.......................................

4·15

II

1800-9AOO

TABLE OF CONTENTS (cont.)

SECTION

5-ADJUSTMENTS

5.1

PURPOSE

................................................................

5-1

5.2

SUMMARY

OF

ADJUSTMENTS

...............................................

5-1

5.3

CARRIAGE

TIMING

BELT

TENSION

............................................

5-2

5.4

PAPER

FEED

BELT

TENSION

................................................

5-3

5.5

PRINT

HEAD

CLEARANCE

...................................................

5-4

5.6

CARRIAGE

HOME

POSITION

.................................................

5-5

5.

7

TRACTOR

PIN

WHEEL

ALIGNMENT

...........................................

5-6

5.8

IDLE

GEAR

AXIAL

PLAY

....................................................

5-7

SECTION

6-TROUBLESHOOTING

CHARTS

6.1

PURPOSE

................................................................

6-1

6.2

PREPARING

TO

TROUBLESHOOT

.............................................

6-1

6.3

TROUBLESHOOTING

FLOWCHARTS

...........................................

6-2

6.4

MECHANICAL

FAULT

CHART

...............................................

6-10

SECTION

7-CIRCUIT

DIAGRAMS

7.1

PURPOSE

................................................................

7-1

7.2

PRIMARY

POWER

CIRCUIT

&

LINE

FILTER

.....................................

7-1

7.3

LOGIC

DIAGRAMS

.........................................................

7-1

7.4

CONNECTOR

LAYOUT

DIAGRAM

..............................................

7-7

7.5

CONNECTOR

PIN

ASSIGNMENTS

.............................................

7-8

7.6

WAVEFORMS

.............................................................

7-9

7.7

PCB

LAYOUT

............................................................

7-13

SECTION

8-ILLUSTRATED

PARTS

8.1

COVERAGE

...............................................................

8-1

8.2

MINOR

HARDWARE

........................................................

8-1

8.3

ILLUSTRATED

PARTS

SUMMARY

.............................................

8-1

APPENDIX

A-SERIAL

INTERFACE

A.1

DESCRIPTION

............................................................

A-1

A.2

PREPARATION

............................................................

A-1

A.3

INSTALLATION

...........................................................

A-1

A.4

USER

SELECTABLE

FUNCTIONS

.............................................

A-2

A.5

CONNECTOR

PIN

ASSIGNMENTS

............

;

................................

A-3

A.6

SERIAL

INTERFACE

CONNECTOR

.............................................

A-3

A.

7

SIGNAL

DESCRIPTION

.....................................................

A-4

A.8

INPUT

/OUTPUT

CIRCUIT

CONFIGURATIONS

....................................

A-5

A.9

SERIAL

INTERFACE

INITIAL

FLOW

AND

MEMORY

MAP

............

·

..............

A-6

iii

SECTION 1

INTERFACE & SPECIFICATIONS

1.1

COVERAGE

OF

THIS MANUAL

This service manual contains technical data, procedures, prints and schematics for the maintenance

of

Model H80

and H136 printers. The Model H80

is

an

80

column printer. The Model H136

is

a

156

column printer. Look for

differences in configurations and parts descriptions due to wider platen, longer line length, etc. Most other func-

tions are identical.

1.2 OVERVIEW

The printer consists

of

the print mechanism, control circuits, power supply, control panel and enclosure. The serial

interface

is

an option.

Control panel

(switches,

LEDs)

Power supply

(transformer)

AC

power

1800-9AOO

Print Mechanism

(motor, print head,

sensors, etc.)

~

t

Control circuit!>

(CPU,

ROM,

RAM. -

--

driver, etc.)

Interface

(PIA)

i -

--

_...,

-------

I

I Serial interface I

I

I card (optional) I

I I

I

(CPU,

ACIA) I

I I

L----

-

--------'

Parallel interface

(conforming

to

Centronics

specifications)

Serial interface (RS232C,

current loop)

BASIC BLOCK DIAGRAM

1-1

1.3

SPECIFICATIONS;

HBO,

H138

Hio

H138

Print head

(a) Wire diameter 0.25 mm (.010") 0.25 mm (.010")

(b)

Wi~

pitch 0.353 mm (0.014") 0.353 mm (0.014")

(arranged vertically) (arranged vertically)

(c) Number

of

wires 9 9

(d) Response frequency

960

Hz

960

Hz

Printingspeed

160

characters/sec

160

characters/sec

(at

10

characters/inch) (at

10

characters/inch)

Feed speed 9.1 lines/sec 9.1 lines/sec

(at 6 lines/inch)

(at

6 lines/inch)

Feed method Pin feed (feed force: 2

kg

or

Pin feed (feed force: 2

kg

or

more) more)

Friction feed (feed force: 1

kgor

Friction feed (feed force: 400 g

or

more) more)

Print forms

(a) Fan-folded forms 127-254 mm wide (5-10") 127-431.8 mm wide (5-17")

(b) Cut-sheet forms 127-254 mm wide (5-10") 127-431.8 mm wide (5-17")

(A4 standard)

(A3

standard)

(c) Rolled forms 216 mm (8.5") wide; roll outside Not possible

diameter 70 mm, inside diameter

20 mm

or

less

(d) Paper thickness

With copies 0.13 mm

or

less (.005") 0.13 mm

or

less (.005")

Without copies 0.25 mm

or

less (.010") 0.25 mm or

less

(.010")

Duplicating capability

Up

to 3 sheets including origi-

Up

to

4 sheets including origi-

nal (with 34-kg carbon-backed nal (with 34-kg carbon-backed

paper

or

non-carbon paper)

paper

or

non-carbon paper)

End-of-paperdetection Approx.

65

mm from print po- Approx. 65 mm from print po-

sition to detecting position (End- sition to detecting position (End-

of-paperdetection can be disa- of-paperdetection

is

disabled

bled with a switch.) when levers are set

at

FRICTION

FEED and PAPER SET.)

Paper

cutter l inch

or

less from print position I inch

or

less from print position

Dot pitch (vertical)

Normal pitch 0.353±0.2 mm (1172") 0.353±0.2

mm

(1172")

~pitch

0.118±0.1

mm

(1/216") 0.118±0.1 mm (11216")

Characterpitches

Pica normal standard

10

characters/inch

10

characters/inch

characters (80 characters/line) (156 characters/line)

Pica

NLQ

standard

10

characters/inch

10

characters/inch

characters (80 characters/line) (156 characters/line)

Pica normal enlarged 5 characters/inch 5 characters/inch

characters (40 characters/line)

(78

characters/line)

1800-9AOO

1-2

1.3

SPECIFICATIONS;

H80,

H136

(cont.)

H80

Character pitches (cont.)

Pica NLQ enlarged

characters

Pica normal reduced

characters

Pica normal reduced and

enlarged characters

Elite normal standard

characters

Elite normal enlarged

characters

Graphic dot number 8, 9

8

Line spacing

8

8

8. 9,

16

8

5 characters/inch

(40

characters/line)

17

.14 characters/inch

(132

characters/line)

8.57 characters/inch

(66

characters/line)

12

characters/inch

(96

characters/line)

6 characters/inch

(48

characters/line)

60

dots/inch

(480

dots/line)

72

dots/inch

(576

dots/line)

80

dots/inch

(640

dots/line)

90

dots/inch

(720

dots/line)

120

dots/inch

(960

dots/line)

240

dots/inch (l,920 dots/line)

Adjacent horizontal dots cannot

be printed in

240

dots/inch

mode.

120

dots/inch mode

is

divided

into high speed mode in which

adjacent dots cannot be printed

and normal mode in which all

dots can be printed.

116

inch (4.23 mm)

118

inch (3.18 mm)

7/72 inch (2.47 mm)

n/72 inch

n/216 inch

H136

5 characters/inch

(78

characters/line)

17

.14 characters/inch

(267

characters/line)

8.57 characters/inch

(133

characters/line)

12

characters/inch

(187

characters/line)

6 characters/inch

(93

characters/line)

'60 dots/inch

(936

dots/line)

72

dots/inch (

l,

123

dots/line)

80

dots/inch

(l

,248 dots/line)

90 dots/inch (l,404 dots/line)

120

dots/inch (l,

872

dots/line)

240 dots/inch (3,

744

dots/line)

Adjacent horizontal dots cannot

be printed in

240

dots/inch

mode.

120

dots/inch mode

is

divided

into high speed mode in which

adjacent dots cannot be printed

and normal mode in which all

dots can

be

printed.

116

inch (4.23 mm)

1/8 inch (3.18 mm)

7/72 inch (2.47 mm)

n/72 inch

n/216 inch

(Programmable in units

of

1/216") (Programmable in units

of

11216")

Ink ribbon

(a) Type

(b) Specifications

(c)

Color

(d) Service life

(e)· Storage life

Supply voltage/power

consumption

UL/CSA (USA)

Europe

1800-9AOO

Cassette (ink roller built in)

Nylon,

13

mm wide x 6.5 m,

endless loop

Black

Approx. 3 million characters (pica

standard) at normal temperature

and

humidity

1 year in fixed package at room

temperature

Supply voltage

60Hz

50Hz

120V +

10%

-15%

230V ±

15%

1-3

Cassette (ink roller built in)

Nylon,

13

mm wide x 6.5 m.

endless loop

Black

Approx. 3 million characters (pica

standard}at normal temperature

and humidity

1 year in fixed package at room

temperature

Power consumption

Max.

1.3

A

Max. 120 W

1.3

SPECIFICATIONS;

HBO,

H136

(cont.)

-----

H80 H138

Reliability/durability -

(a) MTBF 2,000 operating hours (under 2,000 operating hours (under

operatingconditions

of

35% operating conditions

of

35%

page density and 25%

or

less page density and 25%

or

less

duty cycle) duty cycle)

(b) Unit service life 12.000 operating hours

or

5 12,000 operating hours

or

5

(excluding print head) years (under operating condi- years (underoperating condi-

tions

of35%

page density and tions

of

35% page density

and

25%

or

less duty cycle) 25%

or

less duty cycle)

(c) Print head life 100 million characters I00 million characters

(16 dots/characterand duty (16 dots/character and duty

cycle

of

wire 35%

or

less) cycle

of

wire 35%

or

less)

Printing operation

I-pass characters Bidirectional logical seeking Bidirectional logical seeking

2-pass characters Same as above (See note.) Same as above (See note.)

Graphic Unidirectional (left to right) Unidirectional (left

to

right)

Note: Passes I and 2

of

the

same character are printed in

the same direction.

Safety regulations Passes

UUCSA/GS

Passes

UUCSA/GS

regulations regulations

Electrical characteristics

(a) Resistance to line noise

The

unit operates properly with

The

unit operates properly with

impulse

of

500 V

or

less (800 ns impulse

of

500 V

or

less (800 ns

square wave). square wave).

Environmental conditions

(a) Temperature

Operating

s·

to40" c 5' to

40'

C

Storage

-30'

to60'

C

-30'

to

60'

C

(b)

Humidity

Operating

20%-90%

r.h. 20%

-90%

r.h.

(no condensation) (no condensation)

Storage

10%-90%

r.h.

10%

-90% r.h.

(no condensation) (no condensation)

(c) Vibration

Operating

0.25Gmax.

0.25

Gmax.

Storage 0.5

Gmax.

0.5

Gmax.

(d) Shock

Operating I G max.(within I ms) I G max.(within 1 ms)

Storage 2 G max. (within 1 ms) 3 G max.(within I ms)

Physical Characteristics

(a) External dimensions

Width 400 mm (15.75#)

598

mm (23.5")

(excluding paper feed knob) (excluding paper feed knob)

Depth 320 mm (12.6") 350 mm (13.8#)

Height

110

mm (4.3")

130

mm (5.1#)

(excluding paper cover) (excluding paper cover)

(b) Weight Approx. 8 kg (17.5 lb.) Approx.

12

kg (26.4 lb.)

1800·9AOO

1-4

1.4 INTERFACE SPECIFICATIONS

1.4.1

Data Transfer

8-bit parallel interface (conforming to Centronics interface specifications)

1.4.2

Input/Output Slgnal Levels

Signal levels

"L"

: +0.0 V

to+0.4

V

"H"

: +2.4 V to +5.25 V

Input/output

conditions

a)

DAT

A I - 8 Connected

to

+5 V via IK ohms.

v+5V

lt<tl 74LS

374

_.,_

__

-tD

Q

_.

b)

STB

c) INPRM

Connected

to

+5

V via 470

ohms

and

to

GND

via 1,000

pf.

+5V

470ll

l1000l'F

74LS14

Connected

to

+5 V via IK

ohms

and,

across 100 ohms.

to

GND

via 0,0IµF.

+5V

tKQ

74LS14

1000

d)

ACKNLG,

FAULT,

SLCT, BUSY, PE

Output

of

an open-collectorgate is connected

to

+5 V via IK ohms.

1800-9AOO

1-5

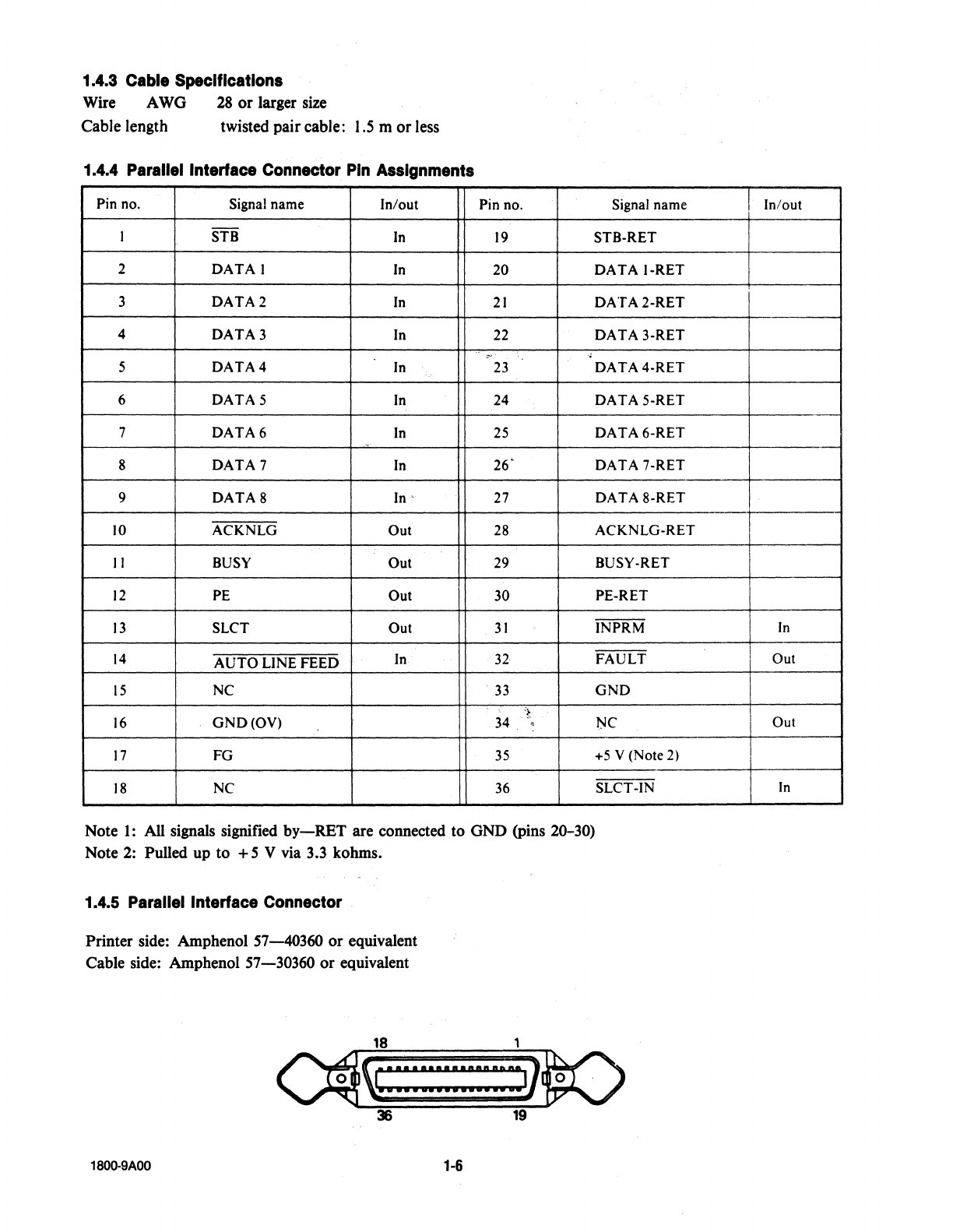

1.4.3

Cable

Specifications

Wire AWO

28

or larger size

Cable length twisted paircable:

1.5

m orless

1.4.4

Parallel

Interlace

Connector

Pin

Assignments

Pin no. Signal name In/out Pin no. Signal name

I STB

In

19

STB-RET

2

DATA!

In

20

3

DATA2

In

21

4

DATA3

In 22

.-

'

5

DATA4

In

23

6

DATA5

In 24

7

DATA6

In

25

8

DATA

7

In

26"

9

DATA8

In

27

JO

ACKNLG Out 28

11

BUSY

Out

29

12

PE Out 30

13

SLCT Out

31

14

AUTO

LINE FEED

In

32

15

NC 33

16

GND(OV)

34

~-

~

17

FG 35

18

NC 36

Note

1:

All signals signified

by-RET

are connected to GND (pins 20-30)

Note 2: Pulled up to +5 V via 3.3 kohms.

1.4.5

Parallel

Interface

Connector

Printer side: Amphenol

57-40360

or equivalent

Cable side: Amphenol

57-30360

or equivalent

18

~:

::

:

:::::::::::

::i]

36 19

1800-9AOO

1-6

DATA

1-RET

DATA2-RET

DATA

3-RET

DATA4-RET

DATA

5-RET

DATA

6-RET

DATA

7-RET

DATA

8-RET

ACKNLG-RET

BUSY-RET

PE-RET

INPRM

FAULT

GND

NC

+5

V (Note 2)

SLCT-IN

Jn/out

--

--

+

In

I

I

Out

Out

In

1.4.6 Description of Input Signals

(a)

DATA I - 8 O Bits 1 - 8

of

character code and image data

O Read into the printer strobed by STB.

O DATA I - 8 should not vary while STB =

L.

--

(b)

STB O Strobe signal to read DATA I - 8

O STB

is

effective when BUSY=

L.

O The next STB should not be output before ACKNLG appears.

(c)

INPRM o Signal to initialize the printer

O

If

INPRM appears when the priater

is

operating,

it

stops imme-

diately. Initialization

is

executed at the rise

of

INPRM from

"L"

to

"H".

~

0 INPRM I i

-t----1-

Sµs(min)

·~

--

(d)

ACKNLG 0 Acknowledge signal responding to STB

O

The

next STB should not be output before ACKNLG returns.

O ACKNLG

is

output independently

of

STB under the following

conditions.

a)

INPRM has appeared after power-on to put the unit

in

ON-

LINE mode.

b) OFF-LINE mode has changed to ON-LINE.

(e)

BUSY 0 When BUSY is H, the unit

is

busy.

0 When BUSY

is

L, the unit

is

ready. ACKNLG

is

output when

BUSY decays to L.

o BUSY is

Hin

OFF-LINE mode.

<0

PE 0 PE rises to H when paper runs out.

• Except when the paper sensor switch

of

the SO-characters/line

printer

is

set to

CUT

SHEET,

or

when the paper release lever

of

the 156-characters/line printer

is

set to a position other than

PIN FEED.

(g)

SLCT o When SLCT

is

H, the unit

is

selected.

(h) FAULT O FAULT

is

Lin

the following conditions.

a)

When paper

is

out.

b) In off-line mode

(i)

AUTO

LINE FEED 0 When AUTO LINE FEED

is

L, one linefeed

is

executed

following execution

of

CR.

(j)

SLCT-IN O When SLCT-IN is L, the unit

is

selected.

1800-9AOO

1-7

1.4.7 Timing Diagram (Parallel Interface)

Tt

T2

T3

DATA

STi

_Jf1-t

--

BUSY

ACKNLG

:=:-_:::::::-_r=--=---=-~~

Tl

T2

T3

T4

0.5

0.5

0.5

4.0

µs(min)

µs (min)

µs(min)

µs(min)

~4uS

Note:

The

timing

of

CD

can be selected with

jumper

J5

of

the

80-characters/line printer

or

J3

of

the

156-characters/line printer. When the machine leaves the factory, the timing is set

to@.

1.4.8 Optional Interface

Serial interface (RS-232C

or

current loop) can be incorporated by installingan option card.

1800-9AOO

1-8

2.1

GENERAL

SECTION 2

THEORY

OF

OPERATION

This sectioncontains block diagrams, timing diagrams, flow charts, electroniccircuits

and

descriptions

of

the func-

tions

of

this printer. Differences between the 80-column

and

156-column units are included.

180Q.9AOO

2-1

PowerON

f--

Reset

* 4MHz

6MHz 2.2

CONTROL

CARD

BLOCK

DIAGRAM

MPU

6802/68A02

HBO

$0800 -

$1

FFF

H136

$3800-$5FFF

OataBUS

ADR

BUS

$0090

-

$0093

! Shift

I

P.ulse

~

',,

,~.,__

__

---'

------v

•'

PIA

I

Feed

Pulse

D B

ff

6B21/

ata

u er

68

A

21

1----l~

80

characters/line

6Kt-9---+-+--+--__.

611 3 x 3

Panel

~

56 characters/line 1

OK

,..

'

SW

___

_.

(RAM)

.,.__--+'.___.....__,.

6116+6264

$00CO -$00C3

$COOO

-

$FFFF

PROG&

CG

ROM

12K

HBO

$2000-

$3FFF

H136

$AOOO

-$BFFF

r---~-----------

I NLQCG NLQCG

I

• Option

ROM

'

•

ROM

I

I

(RAM)

'

r--i 8 K

------·-

SK

f--,

PPl-2

Dip.SW

8255A

$00AO -

$00A3

1

1

Dip.

SW

PPl-1

~--~

ii

Print

~

$00E0,$00FO Signal

----V

8255A

L

__

-I

__

...

L--...1

$00FO NLQCG

Selectflip-flop I $00EO

$0098

-$009F

PTM

6840/68A40

*NOTE-4

MHz IS FOR

140

CPS UNIT;

6 MHz IS FOR

160

CPS

UNIT.

1800-9AOO

-

Address

Decoder

2-2

$0080

Hand

1"

Shake

Signal~---,/

Data

Latch

+24V: MotorPrint Head

+SV:

IC

LSI

GND:

t-

en

0

:I:

2.3 MEMORY MAP

HBO

H138

$0000

$0000

WORK&STACK

AREA

(Within

6802)

007F 007F Data Latch

0080 0080

0090 0090

1/0 ports (6821)

Data latch strobe

0093 0093 I

1-

0098 0098

...

1

---------

009F 009F

OOAO

OOAO

OOA3

OOA3

ooco

ooco

OOC3

OOC3

I

I

OOEO

OOEO

I

OOFF

I

OOFF

I

I

0800 3800 I

PTM

(6840)

PPI

1

(8255A)

PPI

2 (8255A)

CG

select

Data buffer

5-RAM

80

characters/line

HBO

6Kbytes

1

56

characters/line

1FFF

SFFF

H136

10Kbytes

2000

3FFF

cooo

FFFF

1800-9AOO

I

I

AOOO

~

1

-------~

NLQROM

SK bytes

BFFF

.____

______

_.

I

COOO

r

1

-------~

Program (firmware)

CG

ROM

(16K bytes)

FFFF

..._

_____

__.

l/O_Ports

~

D7

D6

D5

D4 D3 D2

D1

DO

Remarks

$0080(R)

DATA

DATA

DATA

DATA

DATA DATA

DATA DATA

8-b1t parallel

8 7 6 5 4 3 2 1 data in

ONLINE

ALARM

ONLINE

LF

FF

I\

PAPER

HOME

Control panel

$0090(R)

POSI-

LED LED

SWITCH

SWITCH

SWl1t:H

EMPTY

TION

inputs

$0092(W)

F~

Ft/13

Ft/12

Ft/11

s~

S4>3

Stb2

St/11

Stepping

motor

outputs

DIP

switch

SOOAO(R)

SW1.-8

SW1,7 SW1-6 SW1-5

' SW1-4 SW1-3 SW1-2

SW1-1

inputs

for

character set

$00A1

(W)

Ne

N1

No

Ns

N•

N•

N2

N1

Wire

dot

pin

outputs

~

\ Interface

signals

$00A2(W)

FAULT

SL~T

BUSY

ACKNLG

PE

N9

Auto-under-

line signal

DIP

switch

$00CD

(R)

SW2-8 SW2-7 SW2-6 SW2-5 SW2-4 SW2-3 SW2-2

SW2-1

for

setting

print

mode

$00CI

(R)

SW4-8

SW4-

7 SW4-6 SW4-5 SW4-4 SW4-3 SW4-2

SW4-1

Not

equipped

(R)

READ

mode

(W) WRITE mode

DIP

switch

for

setting

page

length

•

F,P1

-

4:

Paper feed

motor

pulse

S,P1

-

4:

Carriage

motor

pulse

6802 reset vector address table

Vector Contents

MS

LS

--

FFFF

FFFF

Restart (RES)

FFFC

FFFD

NMI

FFFA FFFB SWI

--

FFF8 FFF9 IRQ

2-3

2.4 INITIALIZATION ROUTINE

Initialize

timers

1-3

1800-9AOO

Turn on power

switch

Inhibitinterrupt

(IRQ)

Set stack pointer

Initialize

MPU registers

Initialize

6821 (PIAI

Initialize

6840(PTMI

Initialize

8255

A (PPl-1, PPl-2)

Initialize 1/0 port

Check

RAM

Initialize

motor

phases

Carriage

motor

Paper feed

motor

Setcarriage

home position

Feed

paperforward

and reverse

No

A

Reid initial values

of

the

DIP

switch

(Printer modesetting. etc.I

Yes

ALARM lamp lights.

Buzzer sounds.

Energize

200

µs

pulses

to

dot.64

times.

2-4

SWITCHES@

POWER ON

LF:ON

FF:OFF

LF:OFF

FF:ON

LF:ON

FF:ON

LF:OFF

FF:OFF

Teat modeprint

NLQ

printmode

isaet.

Hex dumplist

ONLINE

Ready

to

acceptdata

2.5 CONTROL CARD CIRCUITS

l. Power-on-reset circuit

2.

MPU

(68A02)

3.

ROM, RAM

4.

PTM

(68A40)

5.

PIA (68A21)

6.

PPI-l (8255A)

7.

PPI-2 (8255A)

8.

Head driver

9. Power supply

The printer incorporates a

68A02

8-bit microprocessor (MPU). A clock signal

of

1MHz

is

generated from 6 MHz

generated by a quartz crystal, to time data transfer operations.

The

printer consists

of

ROM which stores software, data buffer RAM, printer unit, control panel, buzzer and

LSis (PIA, PTM, PPI) which control interface ports. Each device is controlled by the timing signal output

fromMPU.

2.5.1

Power-On-Reset Circuit

The power-on-reset circuit initializes the MPU and resets the head to the home position.

Power-on-reset initializes the MPU, PIA,

PTM,

and PPI on one hand, and prevents the printer from printing

something

at

the moment

of

power-on on the otherhand.

At the moment

of

power-on, waveforms are as shown in Figure

2-1.

02

©

5V

©

ov

1800-9AOO

J-<"'"""lr-f"

~----~-------CL

L.....::;~:>--

CL

Reset MPU

20ms

• Head initialize

•

PPI

reset

R

13

PSTB

ZSCIZl:S

Figure

2-1

Power-On-Reset

Circuit

2-5

9

Head

driver

circuit

Nl"'-'N9

2.5.2

Microprocessor

Unit

(MPU)

The 68A02 MPU generates the basic clock

of

1 MHz

(1

uS) from a 6 MHz quartz oscillator.

The basic clock signal (E)

is

used to time data transfer operations between the MPU and peripheral LSis.

1800-9AOO

Vee

E

IOIM

r;:t1.RES

RES

_....__,,-oav

ti.RES

..

'7·

VMA-----

E

R/W

Address

From MPU

VMA

E

Address

From MPU

VMA

DATA

FromMPU

Figure

2-2

Re~et

Timing

530ns

max.

Figure

2-3

Read

Operation

Sequence

-------tcrc

1µ1

max.

Invalid da.ta

area

2.4V

0.4V

450ns

225ns ma11.

toow

2.4V

0.4V Doto Valid

Figure

2-4

Write

Operation

Sequence

2-6

This manual suits for next models

1

Table of contents

Popular Cables And Connectors manuals by other brands

ODU

ODU MEDI-SNAP Assembly instructions

Extron electronics

Extron electronics Two Conductor MHR - Mini High Resolution S-Video Cable MHR-2... Specification sheet

hager

hager 4 RJ 45 User instructions

National Instruments

National Instruments NI-XNET LIN operating instructions

Sennheiser

Sennheiser ASP 1 Instructions for use

Davis Instruments

Davis Instruments Crimp-Type Splice Connector install guide