-2 -

TABLE OF CONTENTS

1. Introduction............................................................................................................3

2. A few words about this manual........................................................................3

3. Design......................................................................................................................3

4. Measuring principle..............................................................................................3

5. Unpacking the ITX Suspended Solids Sensor..............................................4

Damages ............................................................................................................ 4

Packaging........................................................................................................... 4

Content............................................................................................................... 4

Optional parts for ITX Suspended Solids Sensor:............................................. 4

6. Mounting of ITX Suspended Solids Sensor...................................................5

Cable Connections ............................................................................................. 5

Installation Tips ................................................................................................. 5

7. Removing the sensor...........................................................................................6

8. Cleaning..................................................................................................................7

Cleaning the Flushing Nozzle............................................................................ 7

Mounting plate for cleaning solenoid valves..................................................... 8

9. Menu for ITX sensor.............................................................................................9

Settings .............................................................................................................. 9

Calibrate............................................................................................................. 9

System.............................................................................................................. 10

10. Calibration ............................................................................................................11

Getting good measurement .............................................................................. 11

Calibration screen............................................................................................ 11

Zero Calibration............................................................................................... 12

Entering sample calibration points –using a sample bucket........................... 13

Alternate calibration, placing sensor in a basin or channel............................. 13

11. Scaling...................................................................................................................14

12. Technical description of sensor ITX 20........................................................15

Optional parts for ITX Suspended Solids Sensor:........................................... 15

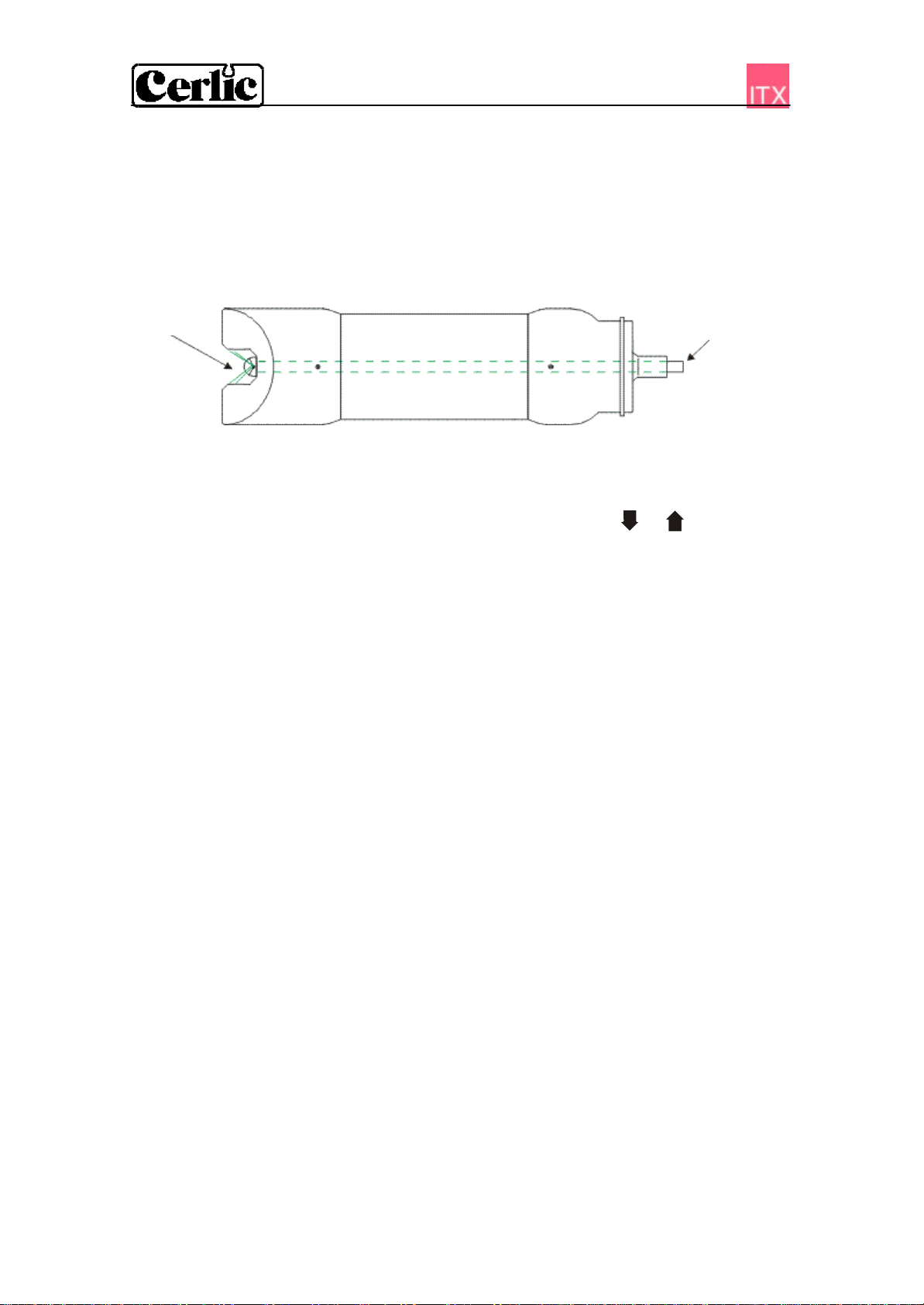

13. Dimensions...........................................................................................................16

Appendix 1, Assembly of handrail mounting kit...............................................17

Appendix 2, Assembly of adjustable slide rail...................................................18

Appendix 3, Support information..........................................................................19

Appendix 4, Setup information..............................................................................21