Product range information

Product guide – CESAB S200 9

Product range information

CESAB S200

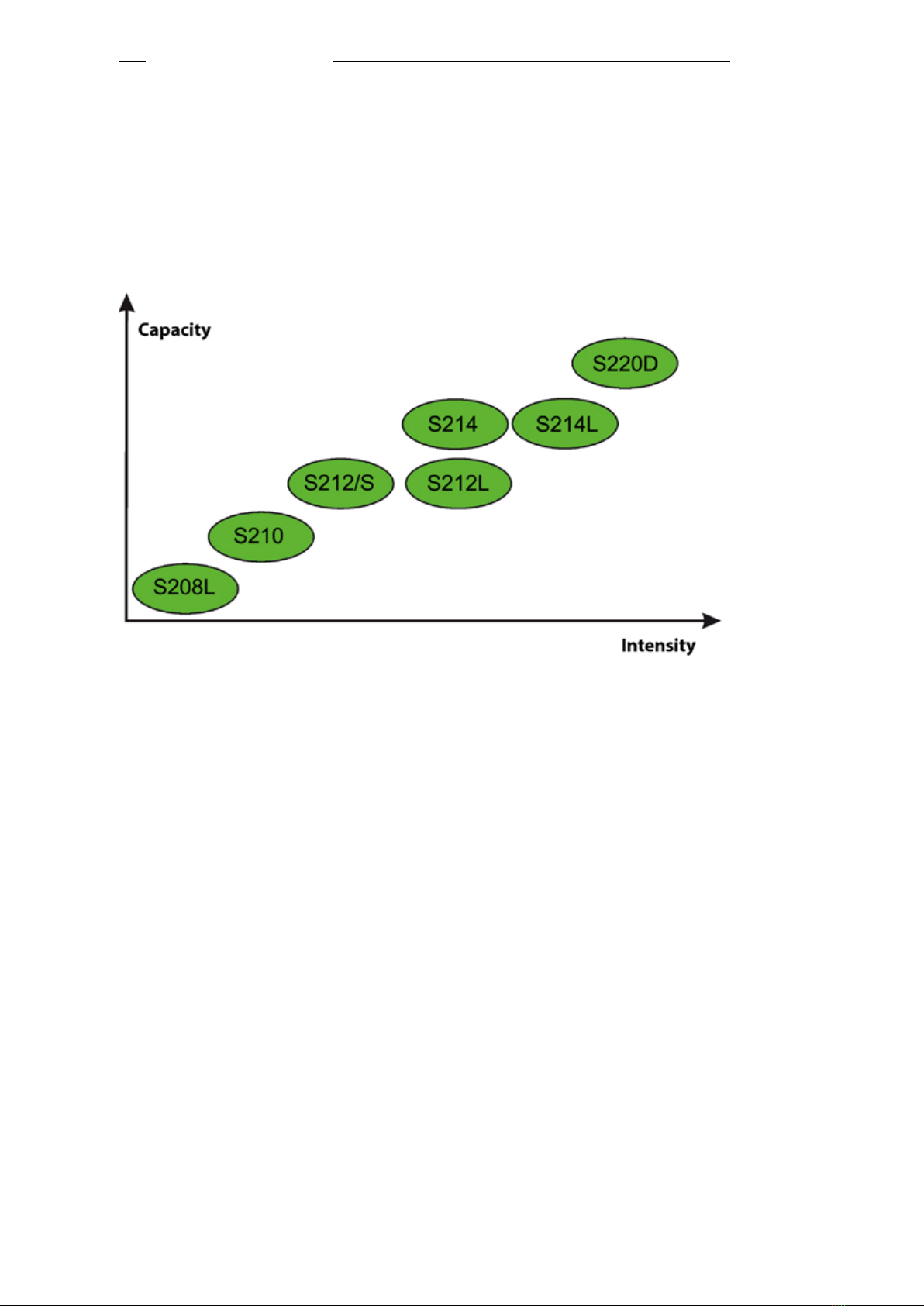

The S200 range is a complete walkie stacker series for light to medium intensive

applications. All trucks in this range are compact and easy to operate. They feature

AC operation and driving characteristics can be programmed and adapted to indi-

vidual operator preferences. This range is complemented by different battery sizes

and a range of masts to choose from. The more powerful models, S212, S212L,

S214, S214L and S220D, also offer battery change to the side.

Most versions are designed for handling of single, open-end pallets (Euro pallet),

however, the S version is a straddle truck with support arms that enables handling

of different pallets, while the D version can be used in double stacking applications.

The L-version with elevating support arms can also be used for loading/unloading

and for driving on uneven oors.

The CESAB model codes can be used as a guide for choosing the right model for

the intended application:

Truck type Intensity class Capacity Feature

S= Stacker pallet truck 2= Low to high

intensity walkie

applications

080 = 800 kg

100 = 1000 kg

120 = 1200 kg

140 = 1400 kg

200 = 2000 kg

L= Lifting support arms

S= Straddle support arms

D= Double stacking