TABLE OF CONTENTS

1. CORRECT APPLICATION ....................................................... Tõrge! Järjehoidjat pole määratletud.

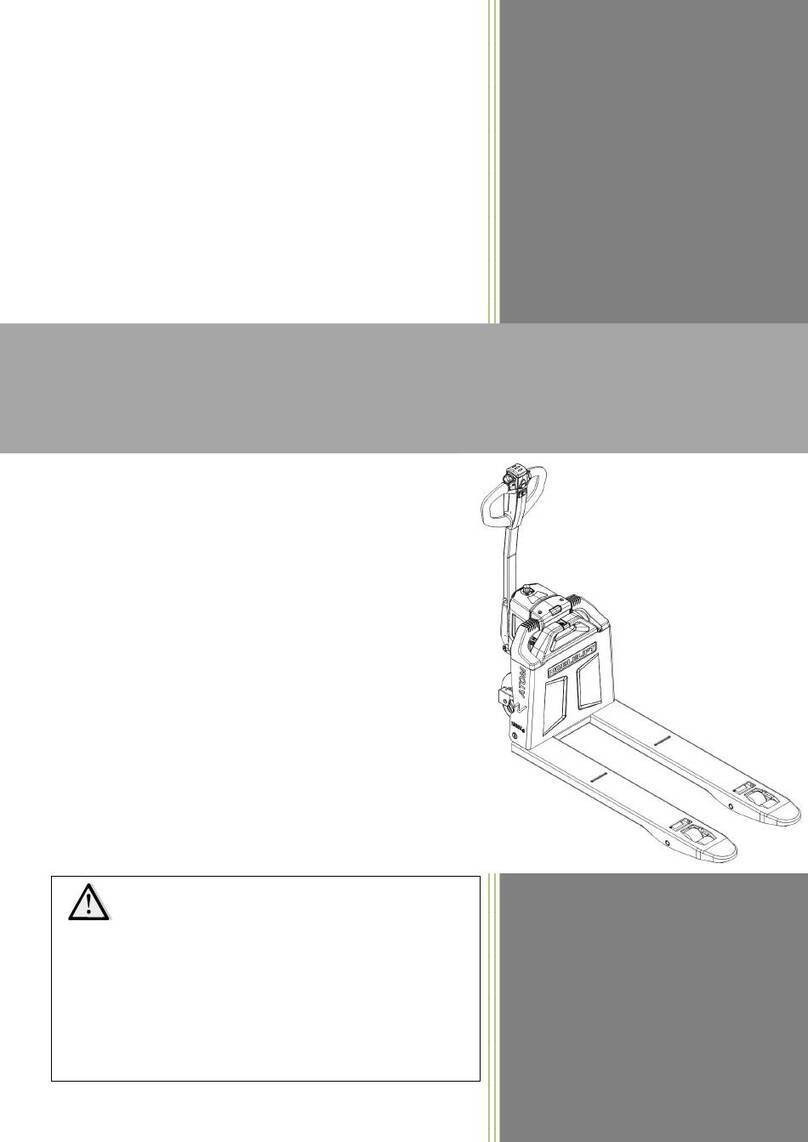

2. DESCRIPTION OF THE PALLET TRUCK............................... Tõrge! Järjehoidjat pole määratletud.

a. Overview of the main components....................................... Tõrge! Järjehoidjat pole määratletud.

b. Main technical data............................................................... Tõrge! Järjehoidjat pole määratletud.

c. Description of the safety devices and warning labels (Europe and other, except USA).................... 8

d. Identification plate............................................................................................................................... 8

3. WARNINGS, RESIDUAL RISK AND SAFETY INSTRUCTIONS .......................................................... 9

4. COMMISSIONING, TRANSPORTING, DECOMMISSIONING ............................................................. 9

a. Commissioning ................................................................................................................................... 9

b. Hoisting/ transportation..................................................................................................................... 10

c. Decommissioning...............................................................................................................................11

5. DAILY INSPECTION .............................................................................................................................11

6. OPERATING INSTRUCTIONS .............................................................................................................11

a. Parking.............................................................................................................................................. 12

b. Lifting ................................................................................................................................................ 12

c. Lowering............................................................................................................................................ 12

d. Driving............................................................................................................................................... 12

e. Steering............................................................................................................................................. 13

f. Braking............................................................................................................................................... 13

g. Malfunctions...................................................................................................................................... 13

h. Emergency........................................................................................................................................ 13

7. WEIGHING TERMINAL........................................................................................................................ 14

a. Accurate weighing............................................................................................................................. 14

b. 1 (Net) + 2 (Tare) = 3 (Gross)........................................................................................................... 14

c. Errors .................................................................................... Tõrge! Järjehoidjat pole määratletud.

d. Zero and tare functions......................................................... Tõrge! Järjehoidjat pole määratletud.

e. Summation (total) function.................................................... Tõrge! Järjehoidjat pole määratletud.

f. Printer (optional) ................................................................................................................................ 16

g. Printout (optional)................................................................. Tõrge! Järjehoidjat pole määratletud.

h. Paper replacement ........................................................................................................................... 17

8. Indicator display ................................................................................................................................... 17

a. Button screen check ......................................................................................................................... 17

b. Default unit settings.......................................................................................................................... 18

c. Backlight mode settings.................................................................................................................... 18

d. Calibration......................................................................................................................................... 18

e. Battery replacement.......................................................................................................................... 19

f. Touch-screen Indicator ...................................................................................................................... 20

g. Sensors installation........................................................................................................................... 20

h. Button functions................................................................................................................................ 21