10

OPERATING INSTRUCTIONS

Read and understand the safety information (See pg. 4).

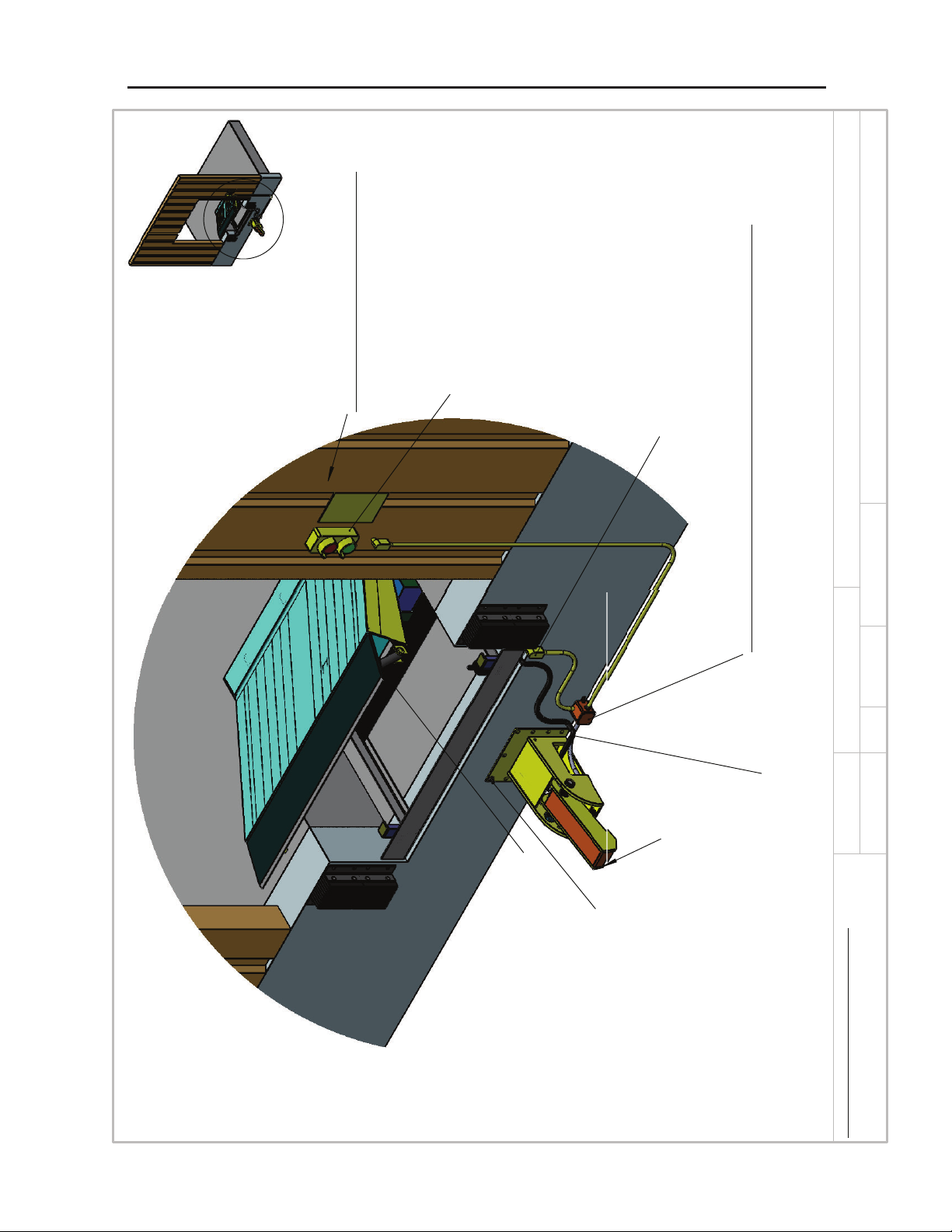

Interior Lights and Controls (See pg. 9)

ExteriorLights(Seepg.9)

ProximitySwitch(Seepg.14)

All of the following conditions must be true prior to operation:

1. Over head door is open.

2. Exterior green light is on.

3. Exterior red light is o.

4. Interior green and amber lights are o.

5. Interior red light is on.

6. Dock leveler and lip are in a stored position.

HYDRAULIC DOCK LEVELER:

ENGAGE (RAISE) RESTRAINT:

STEP 1: Press and hold raise button.

1.Exteriorlightchangesfromgreentored.

2. When restraint arm is fully raised, the dock leveler deck rises and

extendslip.

3. Interior light changes from red to green.

STEP 2: Release raise button.

1.Docklevelerlowerstotraileroorbygravity.

Restraint is now engaged and dock leveler is ready for loading/unloading.

DISENGAGE (LOWER) RESTRAINT:

STEP 1: Press and hold raise button.

1. Dock leveler deck raises, lip lowers to the vertical position for storing.

STEP 2: Release raise button.

1.Docklevelerlowersbygravitytoastored(closed)position.(Proximityswitchisactivated.)

2. Interior light changes from green to red.

3. Truck restraint arm fully lowers.

4.Exteriorlightchangesfromredtogreen.

Dock leveler and truck restraint are now in the stored poistion.

Truck or trailer is now free to depart.

MECHANICAL DOCK LEVELER:

ENGAGE (RAISE) RESTRAINT:

STEP 1: Operate mechanical dock leveler.

1. Pull release chain on dock leveler.

2.Exteriorlightchangesfromgreentored

3.AllInteriorlights(redamber&green)ashandalarmsounds.

4. Walk down dock leveler into truck.

STEP 2: Press and hold RAISE button.

1.Interiorlightschangefromallashingtoredonlyandalarmshutso.

2.Whenrestraintarmfullyraised(apprx.6-8sec.),releaseRAISEbutton.

3. Interior light changes to green.

Restraint is now engaged and dock leveler is ready for loading/unloading.