Contents

1.The Introduction .............................................................................................................1

2.Proper usage.....................................................................................................................2

Modification............................................................................................................................... 2

3.Introduction of the product.........................................................................................3

3.1 Model Overview................................................................................................................ 3

4.Operating principle ........................................................................................................5

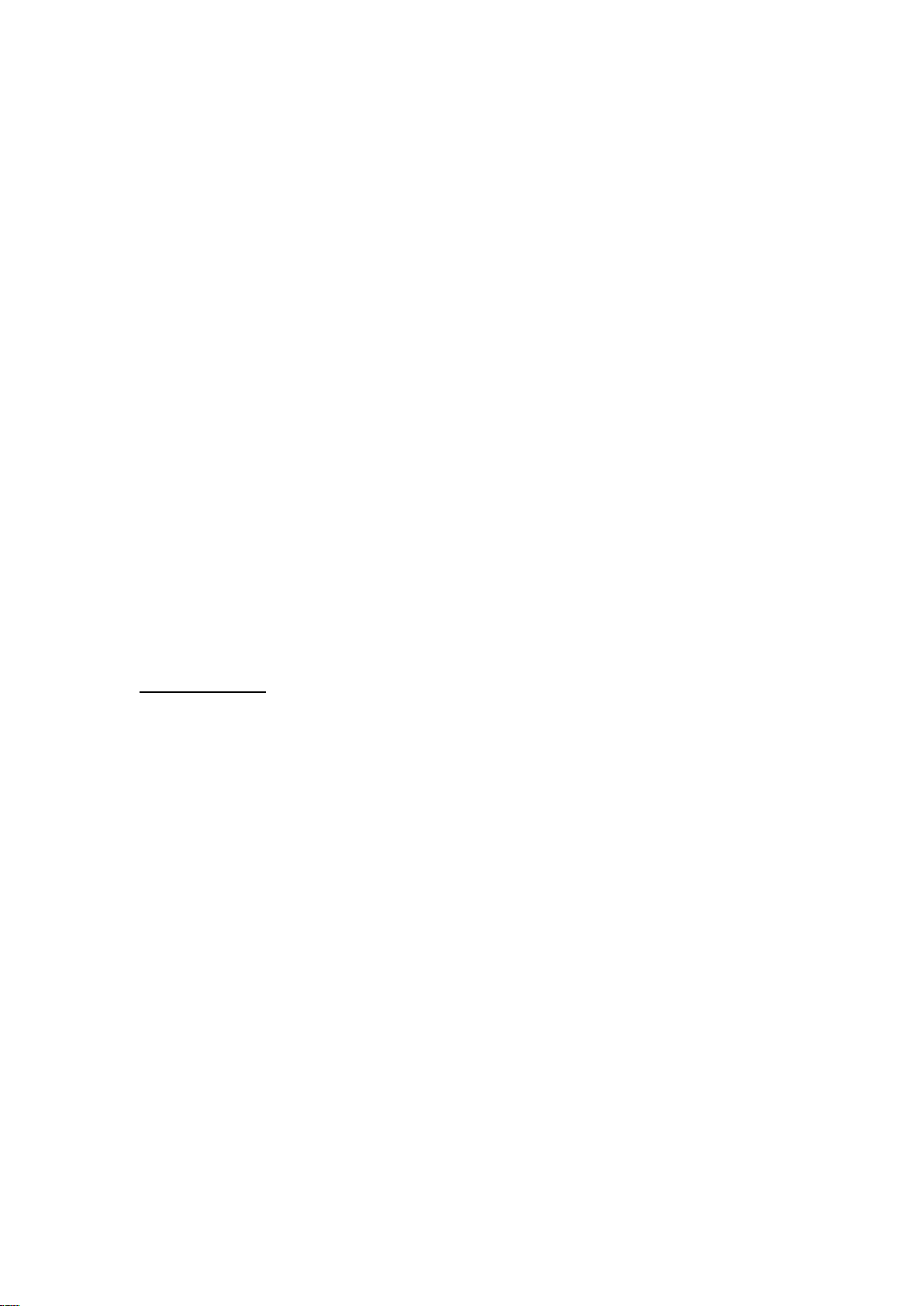

5.Operating principle ........................................................................................................6

5.1Running system.................................................................................................................. 6

5.2 Steering system................................................................................................................. 6

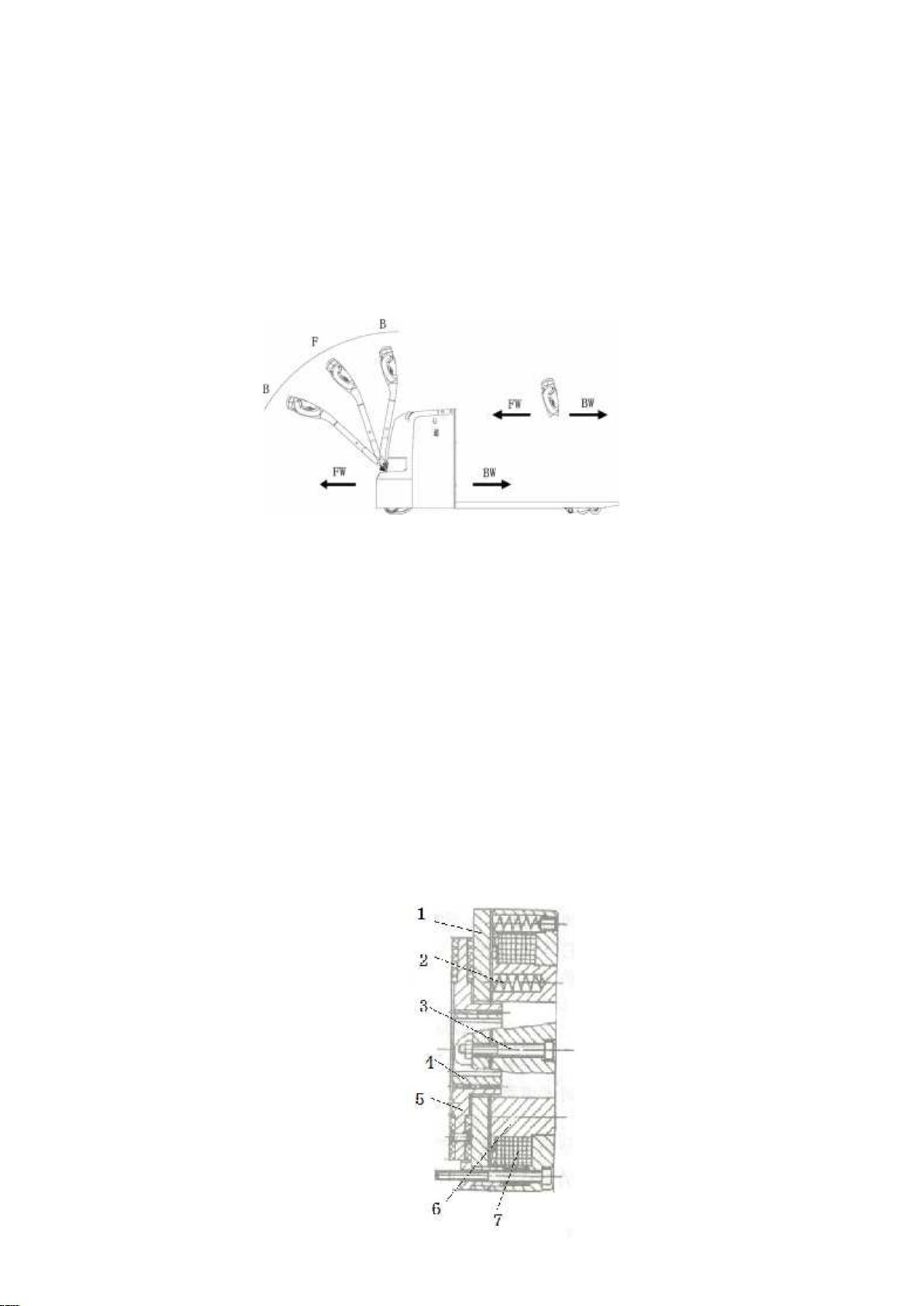

5.3 Braking system.................................................................................................................. 6

5.4 Operating System............................................................................................................. 8

5.5 Electric System.................................................................................................................. 8

5.6 Hydraulic principle.......................................................................................................... 8

6.Electrical Schematic Diagram..................................................................................... 9

7.Hydraulic Schematic Diagram ................................................................................. 10

8.Operating Instruction................................................................................................. 11

8.1 Start, run and parking: .................................................................................................11

8.2The usage of emergency safety switch....................................................................11

8.3 The usage of horn button. ...........................................................................................11

8.4 Battery capacity indicator...........................................................................................11

8.5 Handling stacking operation......................................................................................12

9.Maintenance................................................................................................................... 13

9.1Safety procedures for repair and maintenance...................................................13

9.2 Daily Maintenance .........................................................................................................14

9.3 Professional Maintenance Manual...........................................................................14

9.4Maintenance, Recharging and Replacement of the accumulator..................16

10.Safety Precautions..................................................................................................... 19

10.1 general rules..................................................................................................................19

10.2 Transportation and storage.....................................................................................19

10.3 Check before Using......................................................................................................20

10.4 Safe Operation...............................................................................................................20

11.Repair Manual ............................................................................................................ 23

11.1 Malfunction analysis...................................................................................................23

11.2 preparation work before repair.............................................................................24

11.3 check the oil content of hydraulic oil...................................................................24

11.4 preparation work before use after maintenance ............................................24