Table of Contents

1 Product Introduction .................................................................................................................................. 1

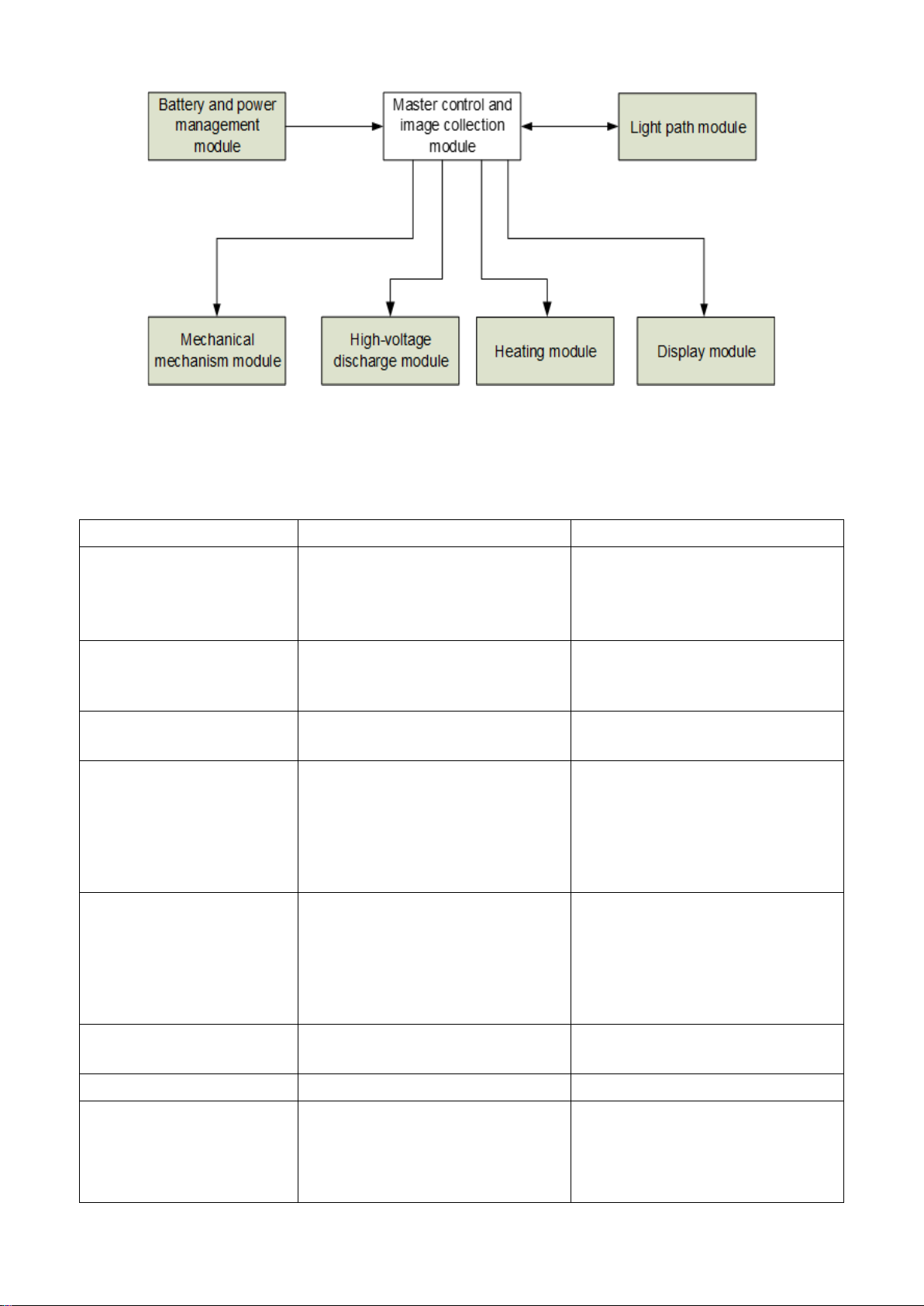

2 Functional Block Diagram ........................................................................................................................... 1

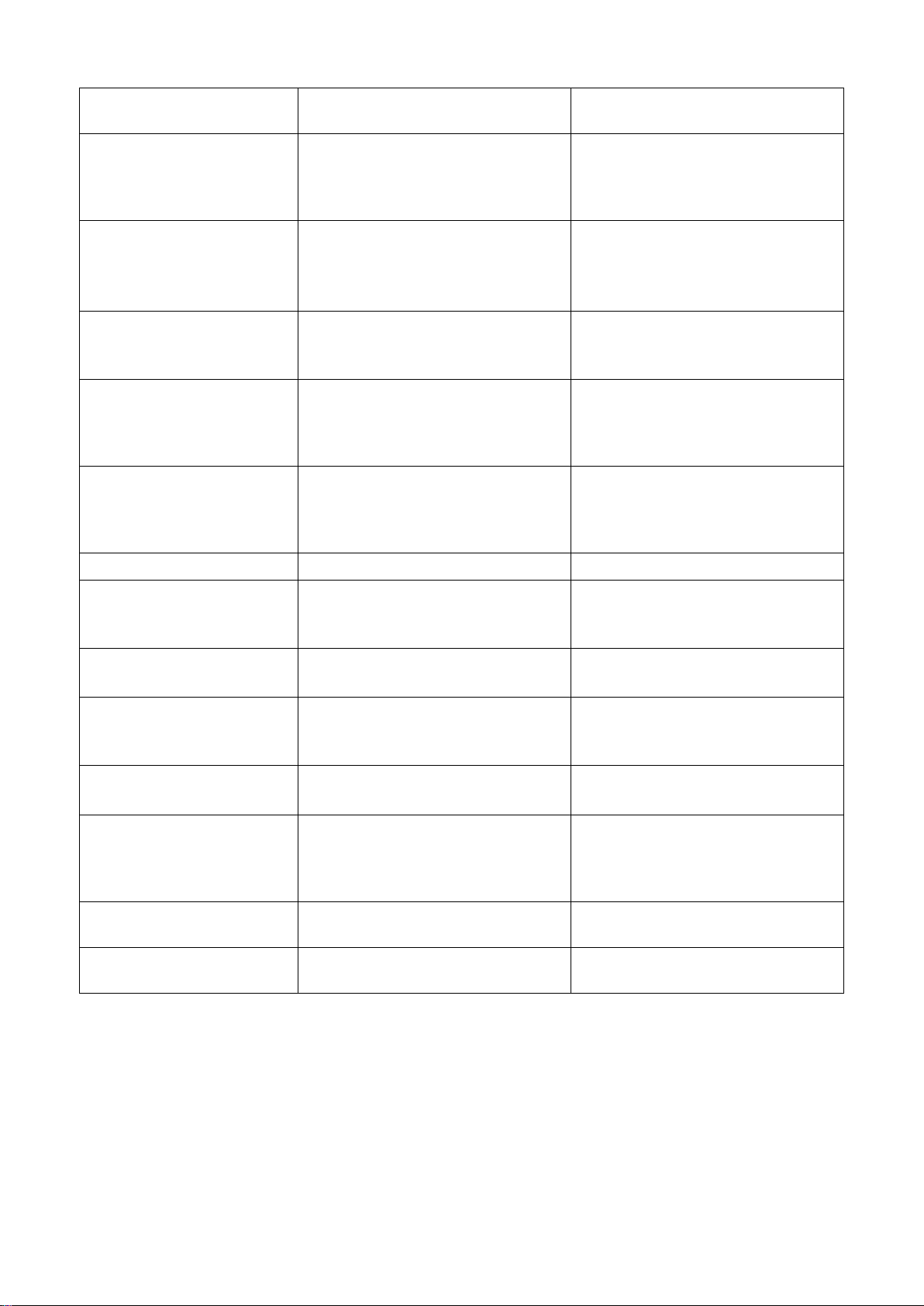

3 Common Fault ............................................................................................................................................ 2

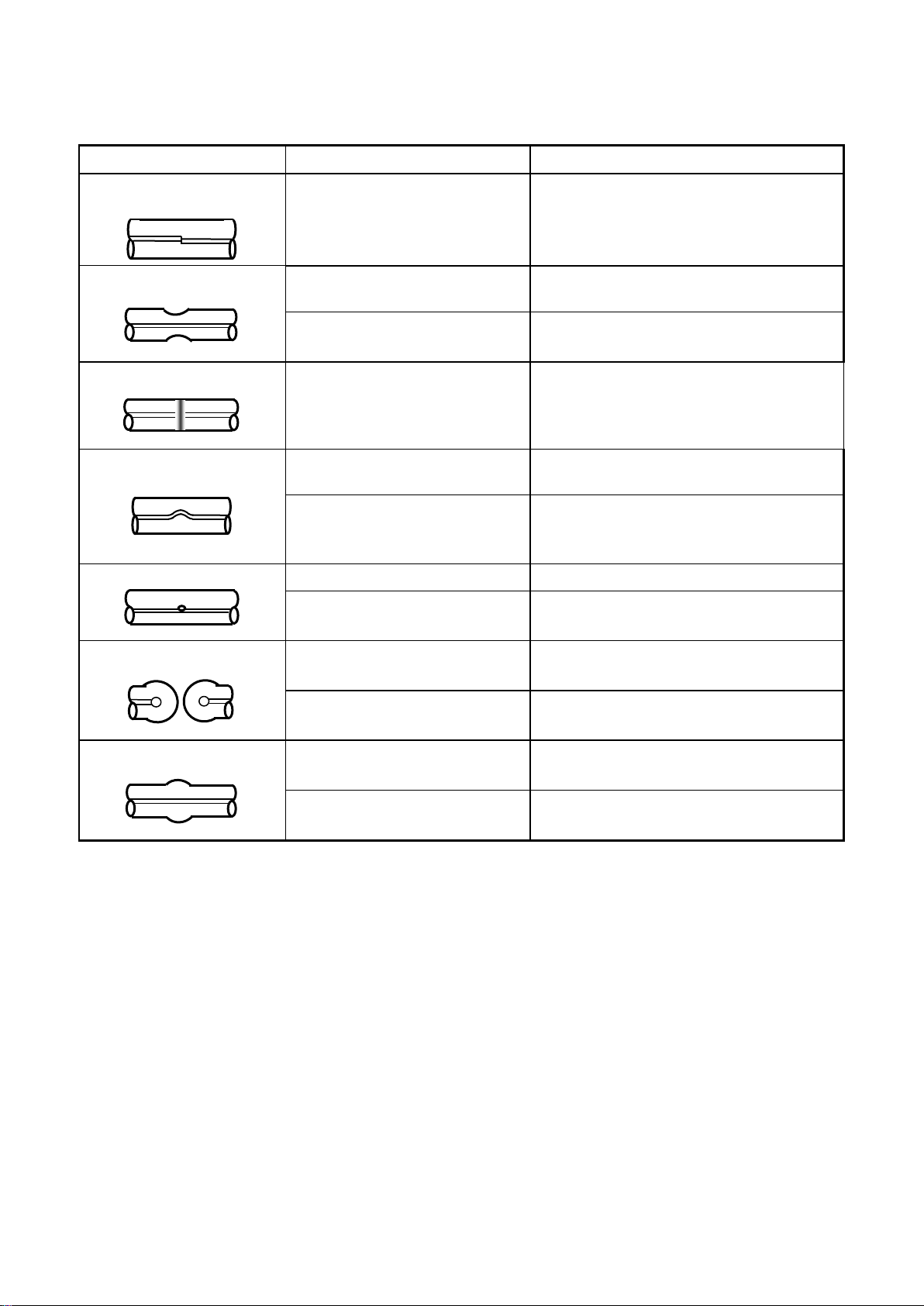

3.1 Common Faults of Instrument............................................................................................................. 2

3.2 Causes of Fusion Loss Increase and Solutions ..................................................................................... 3

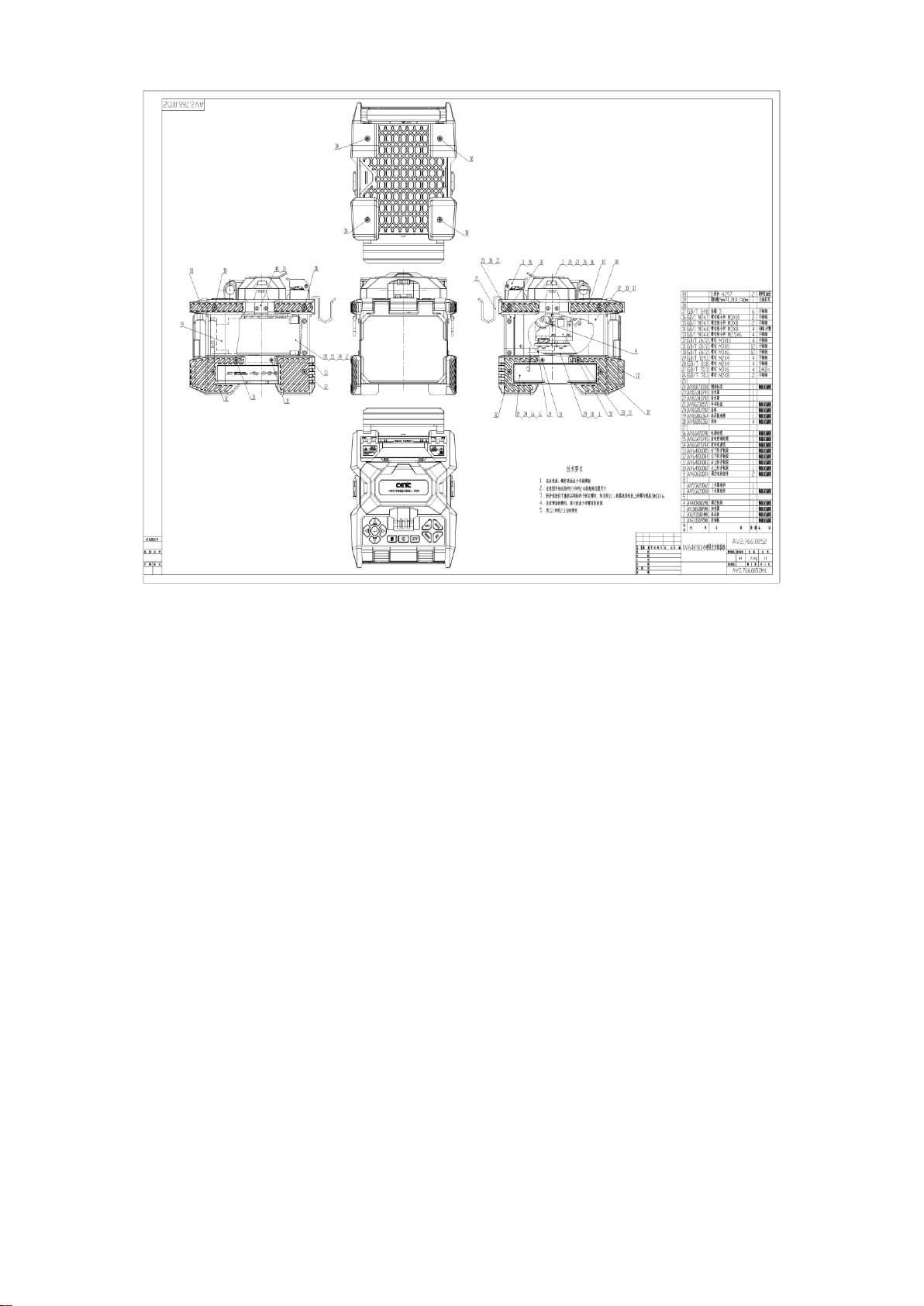

4 Repair of Parts ............................................................................................................................................ 4

4.1 Disassembly ......................................................................................................................................... 4

4.2 Propel Motor ....................................................................................................................................... 5

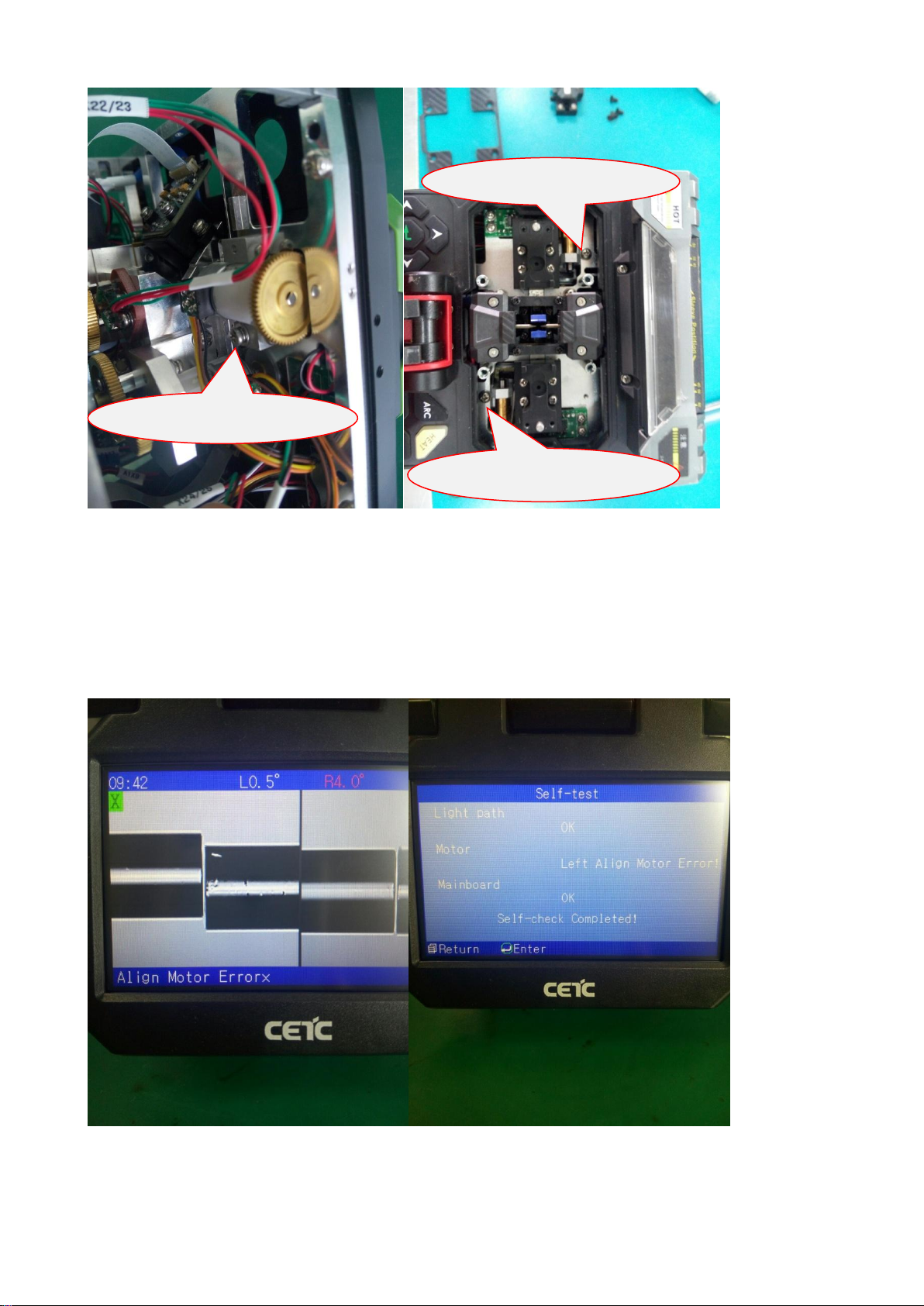

4.3 Align Motor.......................................................................................................................................... 8

4.4 Imaging Lamp .................................................................................................................................... 10

4.5 Heater ................................................................................................................................................ 15

4.6 Power Board ...................................................................................................................................... 16

4.7 High-voltage Board ............................................................................................................................ 17

4.8. Control Board ................................................................................................................................... 18

4.9 Light Path........................................................................................................................................... 20

5 Repair and calibration of Instrument ....................................................................................................... 21

5.1 Software Upgrade.............................................................................................................................. 21

5.2 Cleaning of V-groove ......................................................................................................................... 22

5.3 Cleaning and Replacement of Electrode ........................................................................................... 23

5.4 Adjustment of Electrode Holder........................................................................................................ 24

5.5 Cleaning of Objective Lens ................................................................................................................ 25

5.6 Propelling Distance Correction.......................................................................................................... 25

5.7 Propelling Distance Test .................................................................................................................... 26

5.8 Discharge Correction ......................................................................................................................... 26

5.9 Discharge Test.................................................................................................................................... 26