INSTRUCTIONS BOOK FOR PRESS BRAKE MP1400 CNC 2

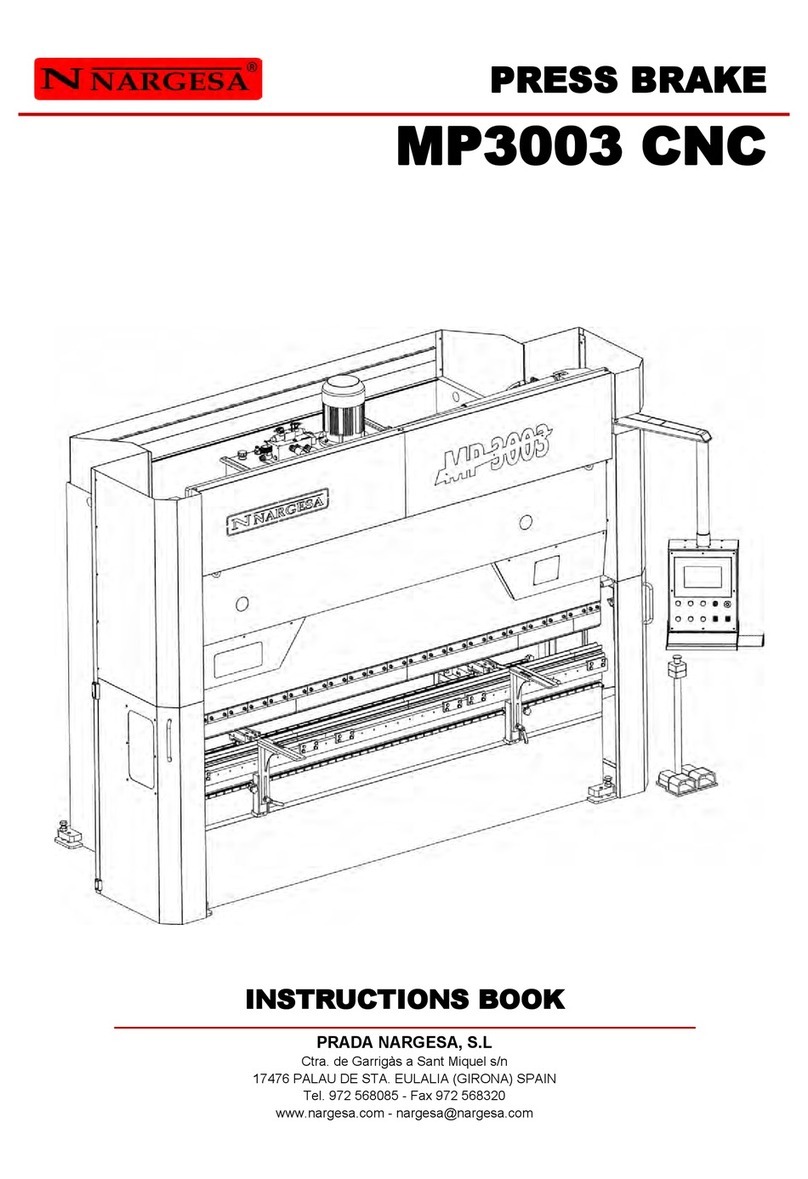

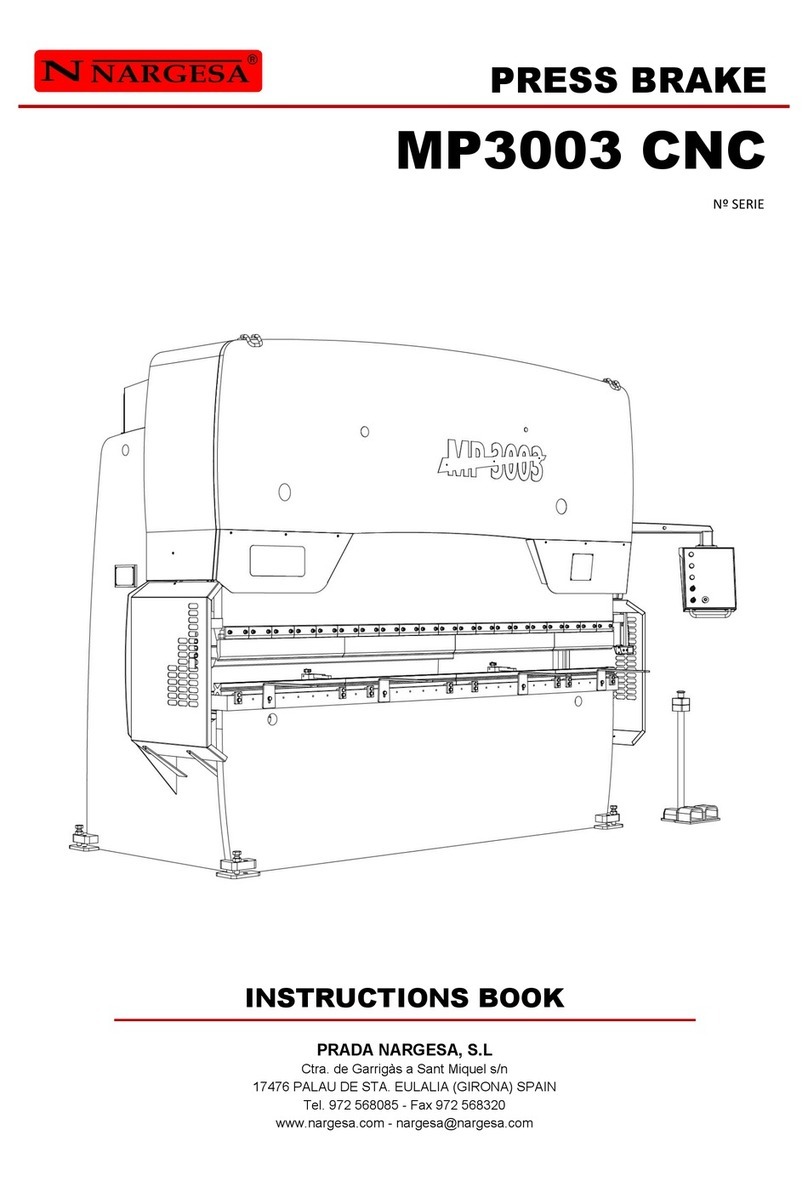

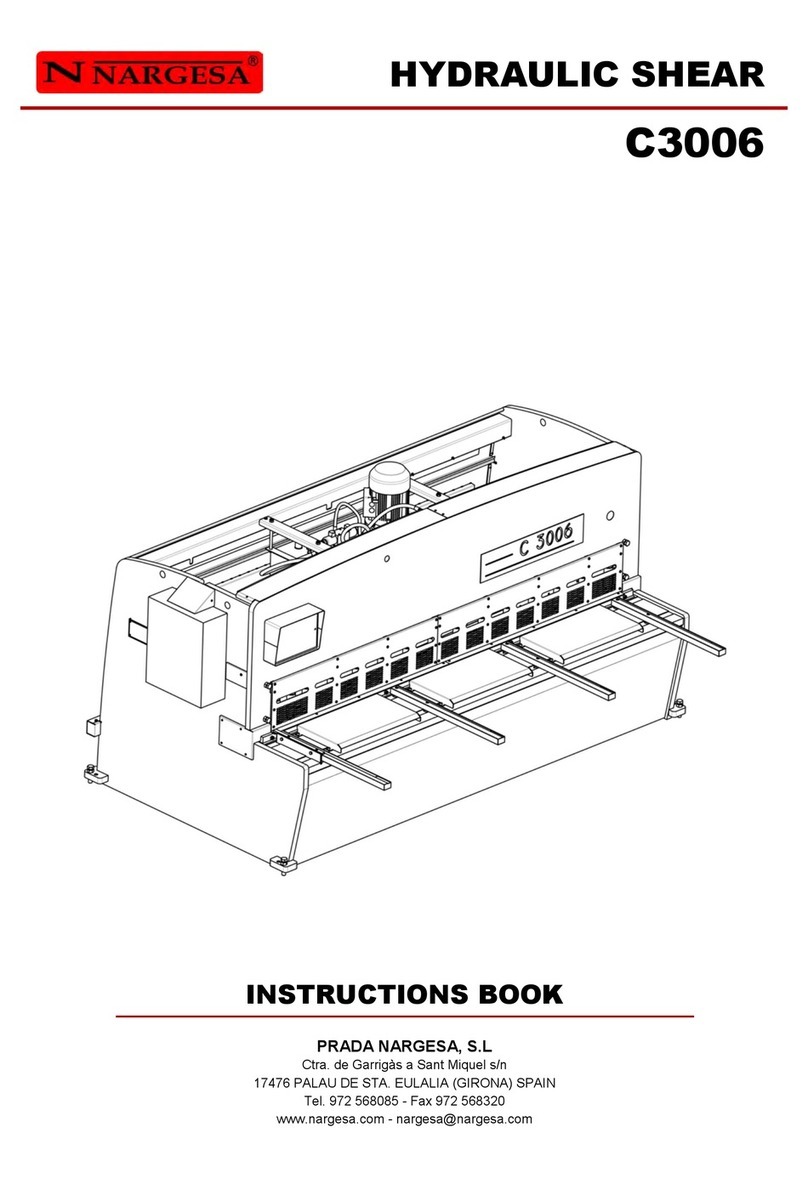

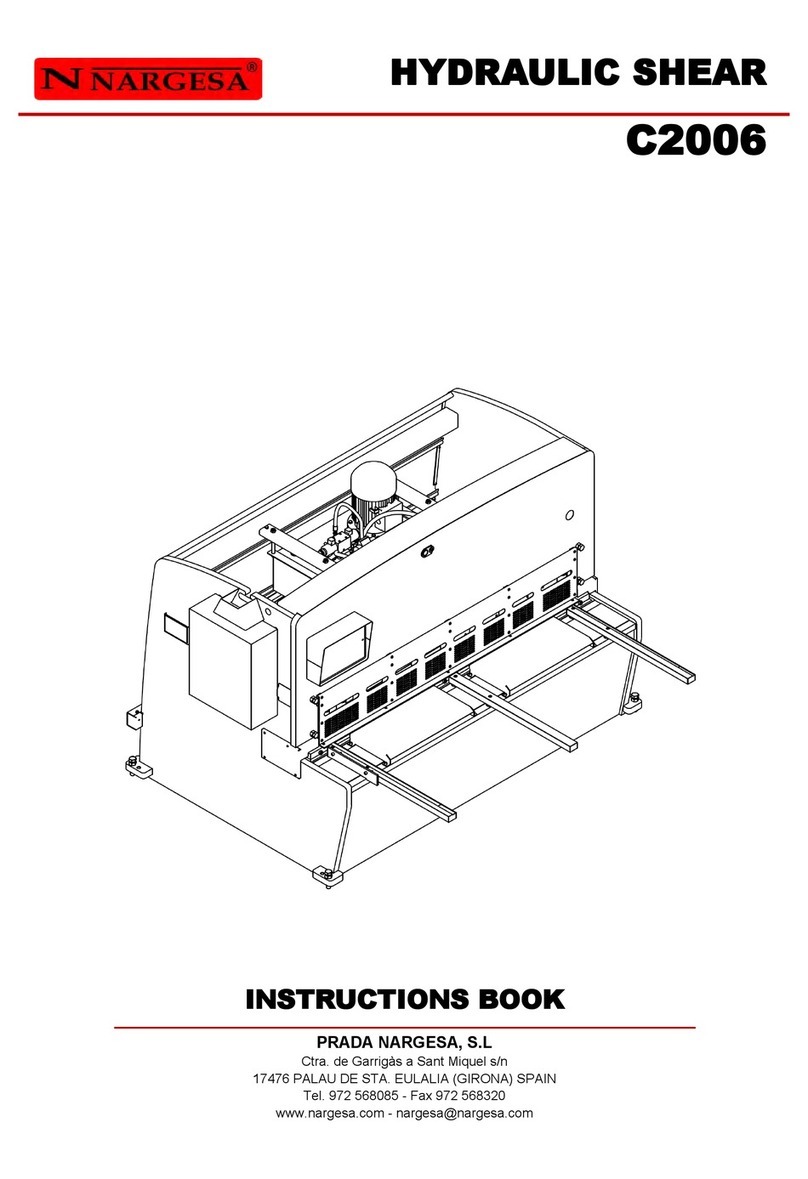

INDICE

1. CHARACTERISTICS OF THE MACHINE ...............................................................................

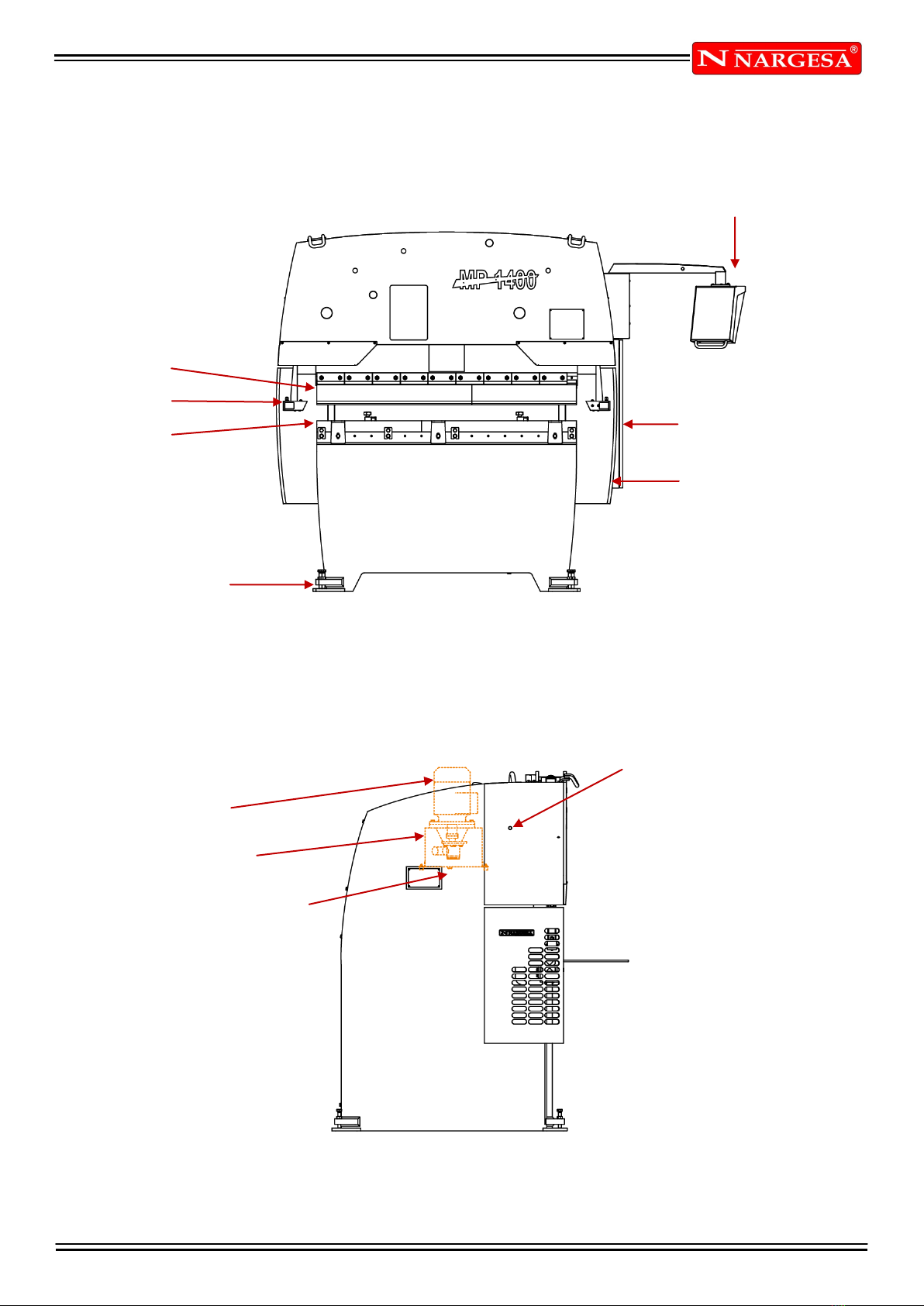

1.1. General dimensions ....................................................................................................

1.2. Description of the machine ..........................................................................................

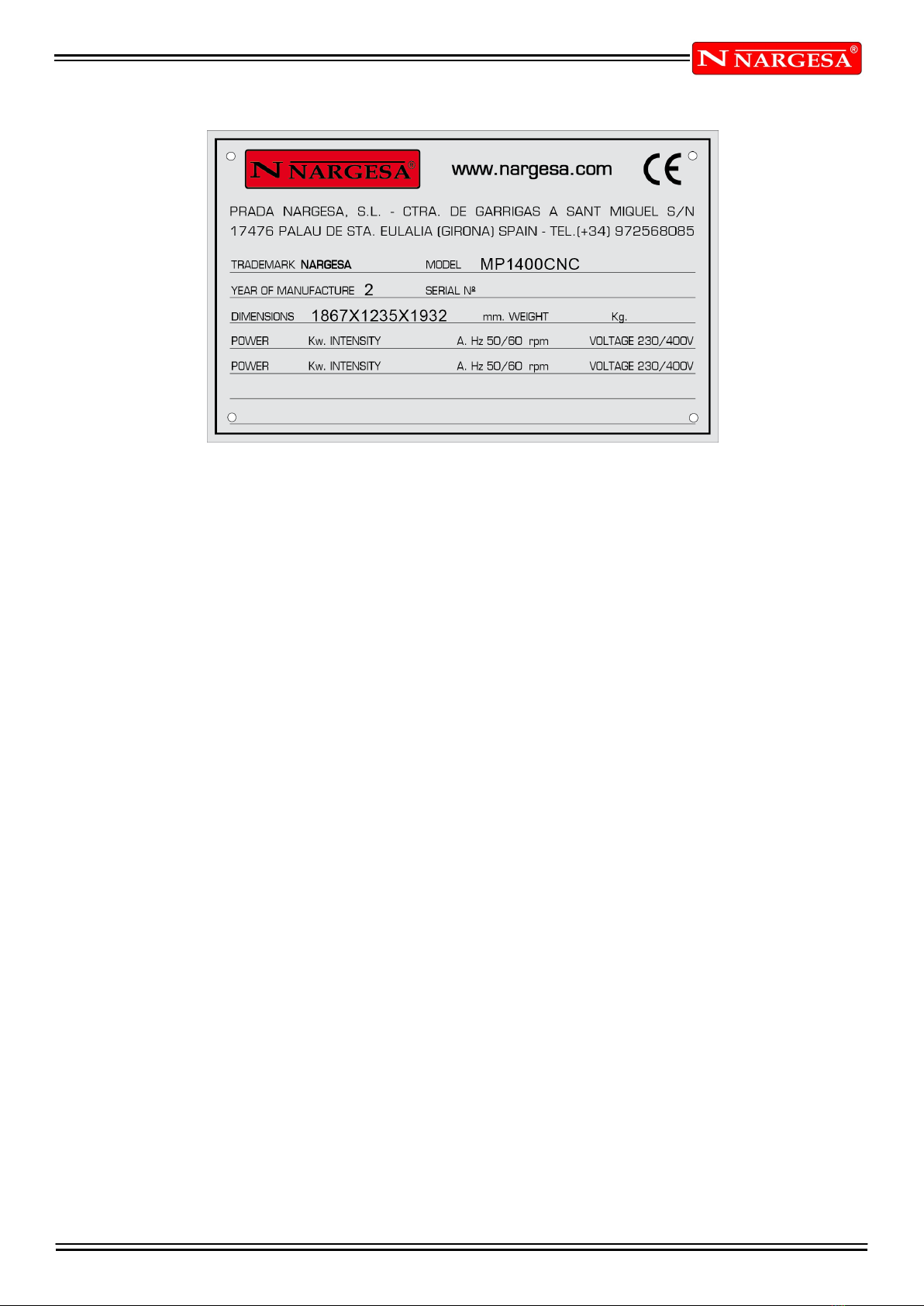

1.3. Identification of the machine .......................................................................................

1.4. General features ……………….…...............................................................................

1.5. Accessories .................................................................................................................

1.5.1. Description of accessories .............................................................................

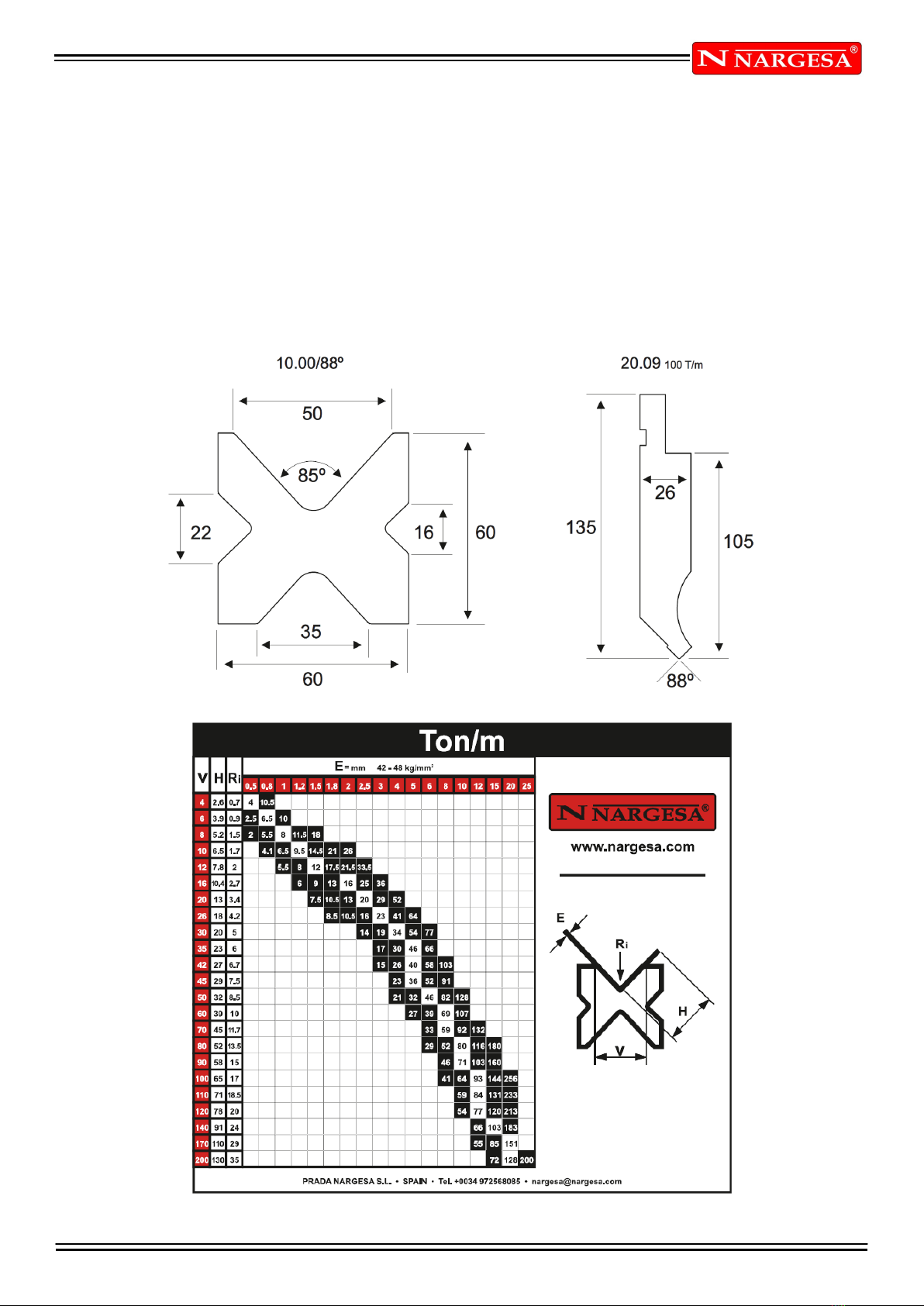

1.5.2. Tooling ...........................................................................................................

1.6. Description of safety devices ......................................................................................

2. TRANSPORTATION AND STORAGE ....................................................................................

2.1. Transportation .............................................................................................................

2.2. Storage conditions ……………….................................................................................

3. MANINTENANCE ....................................................................................................................

3.1. General Maintenance ..................................................................................................

4. INSTALLMENT AND START UP ............................................................................................

4.1. Location of the machine ..............................................................................................

4.2. Dimensions and working site …...................................................................................

4.3. Admissible outer conditions ........................................................................................

4.4. Connection to power supply ………….........................................................................

5. DESCRIPTIVE MEMORY ........................................................................................................

5.1. List of parts ..................................................................................................................

5.2. Hydraulic group ...........................................................................................................

5.3. Gauge .........................................................................................................................

5.4. Upper cylinder ............................................................................................................

5.5. Main cylinder ...............................................................................................................

5.6. Electric maps …….......................................................................................................

5.7. Hydraulic maps …........................................................................................................

6. PROGRAMMING .....................................................................................................................

6.1. Control panel …...........................................................................................................

6.1.1. Introduction ....................................................................................................

6.1.2. Power supply of the machine .........................................................................

4

4

4

5

6

6

6

7

8

9

9

9

10

10

11

11

11

11

12

13

13

21

24

29

31

33

38

39

39

40

40