4

1General safety information

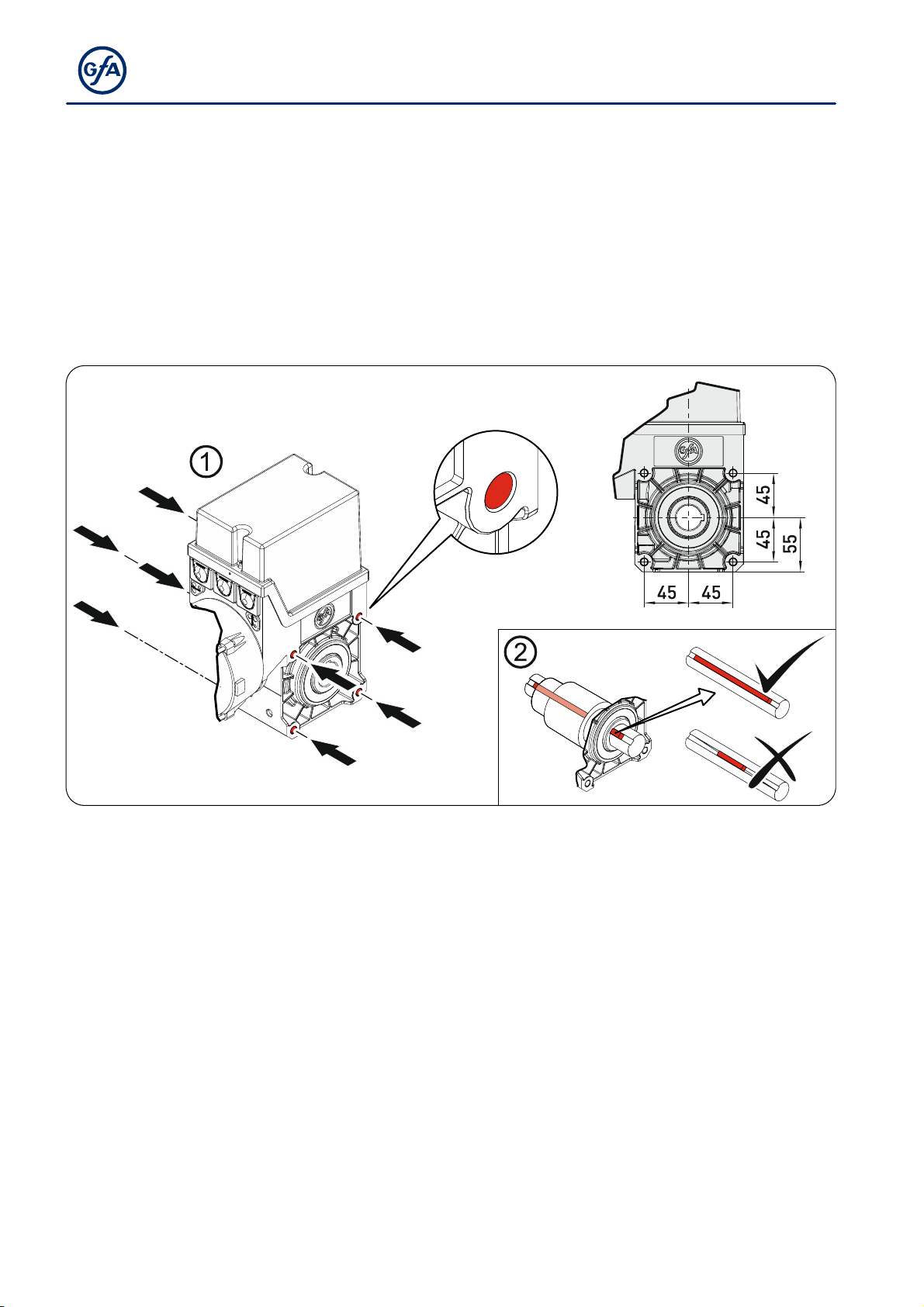

Specified use

The drive unit is only intended for vertically moving sectional doors with full counter-

balancing.

The drive unit must be protected against moisture and aggressive environmental

conditions (such as corrosive substances). The drive units are only suitable for indoor use.

Appropriate protective measures must be taken for outdoor installation. The drive unit is

not intended for hazardous areas. The values specified in the technical data of the drive

unit must not be exceeded. The safe operation can only be ensured if used as specified.

Target audience of these installation instructions

These installation instructions are geared towards qualified persons trained in the handling

of door systems. Expert knowledge, relevant skills and practical experience are what set

apart qualified persons. They are capable of safely carrying out the tasks involving

installation, maintenance and modernisation according to the instructions.

Safe operation

The safe operation of the product can only be ensured if it is used as specified. Follow the

installation instructions. Observe all specifications, especially warnings, when installing the

product in the overall system. GfA is not liable for damage resulting from non-observance

of the installation instructions. The resulting overall system must be reassessed for its

safety in accordance with applicable standards and directives (e.g. CE marking). These

installation instructions refer only to a part of the overall system and are not sufficient as

the sole instructions for the overall system. The installer of the system must prepare the

instructions for the overall system.

We recommend entering the danger area of the system only when the drive unit is at a

standstill.