CGOLDENWALL CZR2014 User manual

User’ s Guide

Please follow the safety instructions in all paragraphs

before turning on the machine

MODEL:CZR2014、108、109、309

This manual should be provided to all users of this device. For best results and to

ensure the durability of your equipment, please read and follow all instructions.

Failure to do so can result in serious injury or catastrophic damage to the user,

machine, supplies, or surrounding area.In addition, safety recommendations must be

strictly followed and extreme precautions must be taken to ensure that only qualified

personnel who have read this guide can use the equipment correctly.

Dear User,

Thank you for choosing our oil press.

The operation and maintenance information, data and materials

listed in this manual have been modified according to the latest version.

Therefore, all content is limited to our current understanding of this type

of press equipment.

Due to continuous technical improvements, we reserve the right to

modify the parameters of the oil press without prior notice. We are not

liable for errors caused by incorrect operation, illegal operation, improper

repair, and use of accessories not provided by the company.

In addition, this series of oil presses is limited to home use. And all

text and drawings in the manual do not indicate they contain the

descriptions of all the items in the shipment.

If you still have problems with the use of this machine, please

contact us in time. We are very happy to serve you!

*Service Contact Information*

Amazon seller: CGOLDENWALL

Service email : sunflowersmile20130401@hotmail.com

Messeger / Whats App: +8613758246804

Facebook : CGOLDENWALL

Precautions

(The following users must obey do not ignore)

Warnings

1. Please use a socket with a grounding protection wire that conforms to

the local electrical safety standards.

2. The oil press must be operated by an adult with full capacity.

Operation

1. Do not press materials other than those specified in this manual.

2. There are a lot of fine sand in rapeseed, which is easy to wear and

squeeze chamber.

3. Whether the oil extracted is related to the method of frying the raw

materials, and has nothing to do with the machine.

4. The pressed material is already slag, and no oil can be squeezed; there

is no need to repeat the re-extrusion, otherwise it will kill the squeeze.

5. Do not put the sundries and hard objects other than the raw materials

into the squeezing chamber to avoid damaging the squeezing chamber.

6. It is strictly forbidden to put fingers and hard objects such as metal

into the press to remove the raw materials, so as to prevent pinching or

damage to the machine.

7. The squeezed oil must be kept for more than one day under the

environment of more than 15 ℃ for natural precipitation and separation

before it can be used for cooking.

Materials

1. Do not squeeze vacuum-packed raw materials, otherwise it will only

produce powder instead of oil.

2. Do not squeeze the raw materials that have been fried to crispness,

otherwise it will only produce powder instead of oil.

3. Do not use the induction cooker or convection oven to fry the raw

materials, otherwise it will only produce powder instead of oil.

4. Do not use a clothes dryer to dry peanuts or other raw materials,

otherwise it will only produce powder instead of oil.

5. Camellia seeds can be roasted fully, and all other raw materials can

only be fried for 8 times at most.

6. When pressing white sesame, please add half of black sesame to

squeeze together, otherwise more slag and powder will be produced.

7. Wet raw materials can not be used for oil extraction, otherwise only

slag will be produced instead of oil, which is likely to jam the squeezing

chamber.

8. Raw materials can be squeezed directly. If it has been fried, it must be

squeezed while it is hot. If it is cooled and then squeezed, it will produce

powder instead of oil.

9. If the peanuts are not dry enough, they can only be fried, roasted or

dehydrated in the microwave oven. Do not expose them to the sun, or

they will only produce powder instead of oil.

10. When heating with microwave, do not use the porcelain plate or

cover with it, because it blocks the microwave, otherwise the porcelain

plate will be heated rather than the materials.

11. Each brand of machine has its own technology. Please do not operate

our machine with the operation requirements of other machines. Please

operate according to our instructions.

Installation

Note:

The surface of each pressing chamber will have uneven concave and

convex spots, and there are also traces of manual running in treatment

at the entrance, which is a unique normal appearance of wear-resistant

metal and a normal new product.

In the manufacturing process, each press is tested with raw materials

before it can be shipped. Although it has been cleaned, there may still

be fine residue. Therefore, the press chamber can be removed and

washed with detergent again.

Please use a socket with safety grounding protection and electrical

safety standards

(The steps of oil extraction are from ①to ⑦in the figure above.)

Oil Extraction Method

Note:

Whether the oil extracted is related to the method of frying the raw

materials, and has nothing to do with the machine.

Under the premise of observing "precautions", the following methods

of oil extraction will be successful once.

Methods:

1. COLD PRESSING

Without heating, the whole process is cold pressed, and the oil

temperature is below 37.8 ℃. It is specially designed for pressing linseed

oil, and fully retains the natural active ingredients. (This method is

limited to pressing linseed. All other raw materials must be heated 10

minutes in advance.)

2. COLD PRESSING

Turn on the heating function of the machine 10 minutes in advance. Don't

turn off the heating in the middle of the process. The purchased dry

materials don't need to be fried but directly squeezed. The oil products are

natural, pure and healthy.

3. HOT PRESSING

If the raw materials are not dry enough, the above two methods of oil

extraction will spray more oil or slag at the slag outlet, then it is

necessary to be fried and then squeezed. Heat the machine 10 minutes in

advance, do not turn off the heating in the middle, use the cooking pot in

the house or oven or microwave to heat the raw materials, remove the

excess water and then squeeze, you must fry in accordance with the

method described in this manual.

4. HOT PRESSING

This method is completely in accordance with the traditional oil

extraction process. Turn on the heating function of the machine 10

minutes in advance, and select peanuts or black sesame (more than half of

the black sesame must be mixed when pressing the white sesame,

otherwise the squeezed things are all slag and not much oil). Stir fry the

ingredients according to the following picture until you smell the strong

fragrance and then get out of the pot. After the water is boiled, put the

fried raw materials into the paving (thickness is about 2cm), leaving 2-3

red jujube-sized vacancies in the middle to let the steam come up, and

cover the steam for 7-8 minutes. Then take the raw materials out and stir

them evenly, so that the oil is mellow and rich, and the oil yield is the

highest. The oil can be released at room temperature for a long time, and

the oily obtained is very fragrant, which is not comparable to the sesame

oil in the market. This is one of the authentic ancient oil pressing

processes.

Several Possible Situations in the Process of Oil

Extraction

Situation:

1. The oil is normal, and the oil can be separated and precipitated by

standing at room temperature above 15 ℃ for 24 hours, indicating that

peanut is good.

2. The oil is normal, and the oil can not be separated and precipitated

after being placed at room temperature above 15 ℃ for 3 days, indicating

that the raw material needs to be replaced.

3. The oil is normal at the beginning for a while, and then there is more

slag at the oil outlet, no oil output, indicating that the water content of the

raw material is too heavy, and the excess water needs to be removed

before pressing (please fry the raw material according to the method

described later).

4. The result is only powder, and no oil at the oil outlet. The bite is

obviously brittle, indicating that there is no water at all. This kind of

situation will appear in Xinjiang, Mongolia, Tibet and other dry areas in

the four seasons of the year and in northern China. Please add 2-3.5%

clean water and mix it evenly before extracting. You can wet your hands,

and then use the hand to pick up half of the raw materials. You can

repeatedly sell the water. These water will be evaporated during the oil

extraction process, but remember not to add too much water.

5. There is oil flowing out at the root of 4 screws, indicating that the raw

material contains too much water, so it needs to be dried and then

extracted. In addition, if the heating time is not more than 10 minutes or

the heater is not close to the pressing chamber, this situation will also

occur.

Note:

Any of the following conditions will lead to excessive slag and powder at

the oil outlet!

Stir fry raw materials in high heat.

Stir fry raw materials in high heat first and then in low heat.

Stir fry raw materials until crispy.

Stir fry raw materials in electromagnetic oven and light wave oven.

Stir fry raw materials and let cool and then extract.

The raw materials are too wet or have been washed and dried.

The raw materials has been exposed to the sun (except camellia seed)

The raw materials have been stored in cold environment.

Your location is in a particularly dry area (such as Xinjiang, Tibet,

etc.).

The heater is not pressed tightly.

The heating of the machine has not been turned on for more than 10

minutes.

Method of Frying Raw Materials

Focus:

Stir-fry ingredients are very important to the success of oil extraction,

don't ignore it!

Don't fry the peanuts with crispy experience. Otherwise, there will be

less oil, no separation and precipitation, and a strong friction noise

from the press chamber. In the other case, only the powder will be

produced, and the press chamber may be stuck.

The moisture content is 1.5-3.5%, if you don’ t know, please do as

follows.

Do not fry on a high fire; use a high fire and then a low fire, or use

only the middle fire. This results in the raw material being cooked on

the outside and the moisture inside.

The raw materials must be squeezed directly, and they must be

squeezed hot after frying. The roasted sesame seeds bought from the

supermarket cannot be squeezed directly. You should add about 10%

water to stir-fry and then squeeze or steam for 7-8 minutes.

When using the following method, 1-1.5kg each time is appropriate

(the raw materials are best squeezed in half an hour). If you fry too

much at one time, the raw materials will become cold during the

squeeze, which is not conducive to flour production.

Our experience is for reference only.

Method:

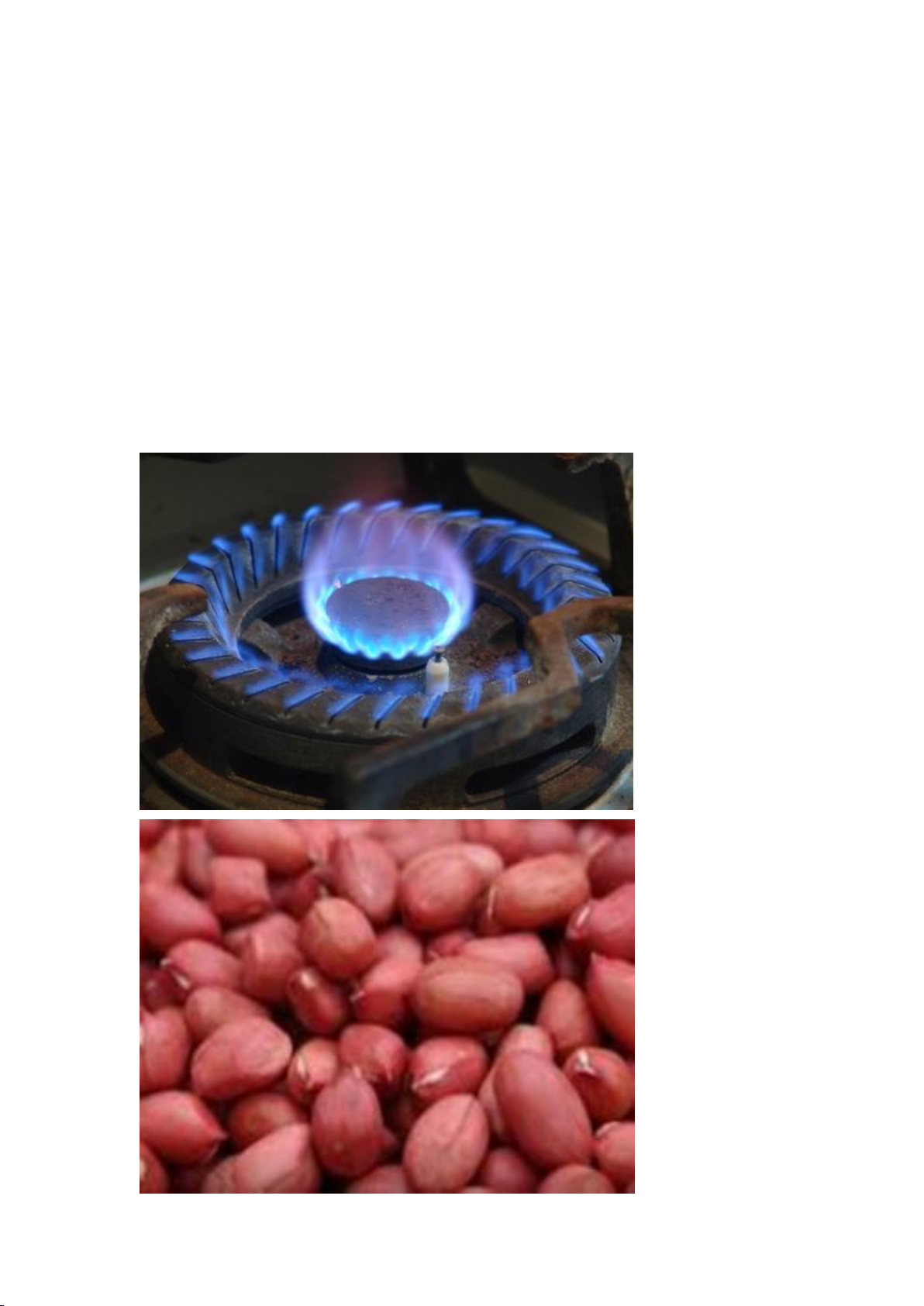

1. [Fried directly]:Turn the fire on the outer ring of the gas stove just to

light (see the picture below), fry the ingredients until the "papa" sounds,

then fry for 3-4 minutes and immediately take it out and squeeze the oil.

When the ingredients are soft and fragrant, they produce the most oil.

And Pay attention to the peanuts of this type in the picture below, fry

until the "papa" sounds, immediately take out the oil.

2. [Microwave oven]: Set to medium heat, and from the beginning until

you hear the "papa" sound after the raw materials are heated, you can take

out to squeeze. According to experience, about 1 pound of raw material is

about 3-minutes-heating. If the raw material has a lot of moisture or the

amount of roast is large, it should be appropriately increased.

3. [Oven with rotating cage]: Adjust the temperature to about 150

degrees and the time to about 25 minutes. Depending on the dryness and

wetness of the raw materials, increase or decrease the time appropriately

(soft and fragrant is the best when biting with teeth). When putting raw

materials into the cage, please leave at least a quarter of the space so that

the raw materials can be turned evenly (there is more slag due to uneven

heating).

Purchase of Raw Materials

1. Do not buy raw materials that have been vacuum packed or stored in

the refrigerator.

2. When buying peanuts, pinch the peanut kernels gently. At least

one-third of the red skin can be separated and fall off, indicating that it is

basically dry.

3. Try not to buy raw materials in oil mills or supermarkets. Just go to

the rice shop. Rice shop owners are generally professional and raw

materials are fresh.

4. It is difficult to make the raw materials dry in the autumn weather. In

the summer, the raw materials need to be exposed to the shell for more

than 3 weeks before they are dry. Please pay special attention to the fact

that the raw materials are difficult to dry, especially new peanuts and

flaxseeds in the autumn harvest season.

5. Special Raw Materials

(1) [Camellia seed]

Camellia seeds can be exposed to the sun (no other ingredients are

allowed) and must be dried to hard. If it is not dry enough, you can use a

microwave oven to adjust to medium high heat, about 1kg each time,

about 9 minutes. Or use an oven with a rotating cage, the temperature is

adjusted to 150 degrees, and roasting for 60 minutes is more appropriate.

No matter what kind of heating method is used, the difference in water

content is large, it is necessary to increase or decrease the time

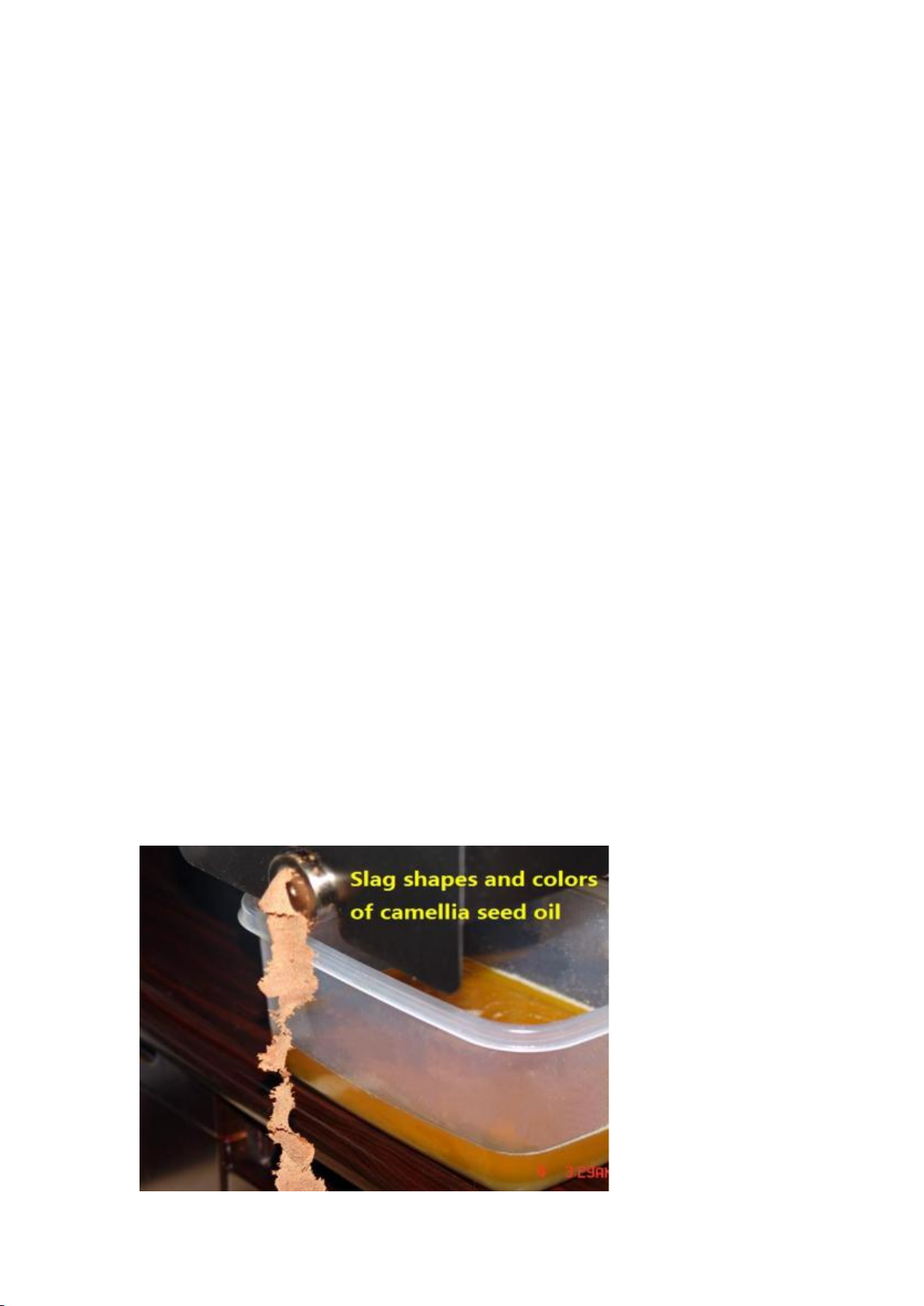

appropriately. Try a small amount first, and the color shown in the figure

below is yellowish.

As long as camellia seeds can enter the machine, it is also possible to

squeeze a small amount of crushed shell (but not too much). Before

crushing large-sized camellia seeds, crush them to the size of peanut

kernels, and do not crush them to a powder, otherwise they cannot enter

the squeeze chamber by themselves, because the tea seeds are more sticky.

Camellia seeds must be completely dry and then squeezed. If strip-shaped

slag appears at the oil outlet, there is only one reason: there must be too

much moisture.

(2)[Flaxseed]

It is special and different from other raw materials: In addition to oil,

flaxseed also contains a layer of natural glue. The longer the storage time

and the lower the temperature, the higher the viscosity of this glue

solution, and the less oil from flaxseed. Under normal circumstances, dry

and fresh flaxseed can be cold pressed without turning on the heating

function. It is normal for the powder to come out within the first half of a

minute, but oil will come out normally after 1 minute. Flaxseeds that are

exposed to cold days or that have been stored for too long or are

repeatedly sun-dried after becoming wet or vacuum-packed will produce

flour when pressed. In the above case, you need to turn on the heating

function at least 10 minutes in advance to start pressing oil, and do not

turn off the heating halfway. The oil output temperature is below 45

degrees, and the oil products will maintain the original natural state (the

raw material harvesting and drying process will reach 50 degrees).

Sometimes, even if you turn on the heating, it is easy to encounter the

phenomenon of flour. You can fry the raw materials slightly and then

squeeze.

Oil often sprays out of the slag outlet or flows out from the root of the 4

screws. This indicates that the raw materials have too much water. Please

dry the water or mix 10-20% fried soybeans before squeezing (if eat raw

yellow Soybean oil you will diarrhea, and the soybeans will be cooked

until the skin is broken.) Use soybean dregs to bring out a part of the

water. The proportion of adding is based on “no fuel injection”. From

small to large, try slowly.

No matter what kind of raw material is squeezed, when there is oil

spraying out at the outlet, there is only one reason--the raw material

contains too much water. Please clean the squeeze chamber and dry the

water first, and then fry the raw material water according to the heat

described above.

(3)[Sesame]

When the raw materials are white sesame seeds and hulled sesame seeds,

be sure to mix with half of the black sesame seeds and squeeze them

together (please refer to the cooking method described above for frying).

In many cities, there are many grain stores or supermarkets that provide

baking and milling services while selling sesame peanuts. Please note that

this kind of roasted sesame is roasted for flour milling. You cannot

directly use it to squeeze oil. Otherwise, in addition to oil-free and

dusting, it may also jam the squeeze chamber. The oil yield of good

sesame seeds is 40% -45%. Nowadays, most sesame seeds are harvested

when they are not fully cooked, resulting in insufficient full particles and

low oil content. Therefore, when buying sesame seeds, choose good

sesame seeds with full particles. Our test is for reference: using the

above-mentioned heat, black sesame 2 and a half pounds, fried for a total

of 10 minutes before and after, the oil yield is 42%.

(4)[Walnut]

Pack the walnut kernels in a cloth bag, and use a wooden stick to lightly

crush the walnut kernels to the size of the peanut kernels. Walnuts with

less oil are easier to enter and squeezed directly; Varieties with high oil

content, although they have few fibers, do not easily enter the squeeze

chamber, so be sure to add a small amount of cooked soybeans to squeeze

together(the amount added is based on normal slag discharge, which

accounts for about 10-20%), so that the oil can be squeezed out at once.

Before pressing, heat the walnut kernels in a microwave oven for 2-3

minutes or set the oven to 150 degrees for about 15 minutes.

The skin of a good walnut is slightly black. The bleached walnut looks

very white, but it is certainly not as good as the natural one. When buying

walnuts, generally choose some with fresh color (fresh brown is best) and

heavier feel. If soaked with chemicals, the walnut kernels in the shell will

also be contaminated. The oil squeezed out from this raw material is

difficult to settle. Please be careful when purchasing. It is recommended

to buy a small amount first and try to buy more after confirmation.

It is recommended to buy a small amount first, and then buy more after

confirmation. Put the walnut oil at room temperature above 15 ℃ for 24

hours. If it can separate and precipitate, the walnut is good. If the

squeezed oil can not be separated after three or four days, please replace

the raw material.

(5)[Yellow okra]

Use mature and high-quality okra seeds for pressing. The yellow okra

seed shell is thick and hard, so be sure to heat it in a microwave oven for

2-3 minutes or stir-fry and soften before squeezing. If the hard shell has

been removed, use a small amount of coriander or soybeans and squeeze

it together. The amount is preferably "slagging normally".

(6)[Pumpkin seeds]

Choose full-grained, ripe small and medium seeds (large pumpkin seeds

are difficult to enter). It can be squeezed raw or pressed in accordance

with the peanut program.

(7)[Soybean]

The oil content of soybean itself is also very low. If you think the cost is

acceptable, you can refer to the peanut procedure, according to the hot

pressing method, stir fry until the skin is cracked and press.

(8)[Sunflower seeds]

Sunflower seeds can be divided into two types: edible sunflower and oil

sunflower. Edible sunflower seeds are large. Oil sunflower is a small

black seed with more oil, which can be squeezed with the shell or

squeezed after the shell is removed; if fried before the squeeze, the oil

will be more. Please refer to the procedure of peanuts for frying and

pressing.

(9)[Rapeseed]

Rapeseed is divided into winter rapeseed and spring rapeseed, and the oil

content is mostly between 30% -40%. When buying, pay attention to

judging that the preferred storage is not too long, no moldy taste, and full

of particles. The yield of rapeseed from different regions and varieties is

quite different. Refer to the method of camellia seeds: Be sure to go after

the water is pressed, otherwise it will be slag. Please note that rapeseed is

extremely abrasive to the press chamber due to its small particles and a

lot of fine sand (cause of the harvest process).

(10)[Perilla seed]

Perilla seeds are divided into medicinal and edible. Please buy edible

perilla seeds when pressing oil. Please refer to the process of flaxseed for

pressing.

(11)[Safflower seeds and hemp kernels]

The shell of safflower seeds and hemp kernels is very thick and hard. It is

best to remove the shell before pressing. If you can't remove the shell,

you must fry the raw materials according to the "hot pressing" method

introduced before. Be sure to squeeze out the ingredients while the

ingredients are hot. First heat up the machine for more than 30 minutes,

then start the oil press switch. Put a small amount at the beginning, and

then fill the hopper after the normal slag discharge. Please squeeze it all

at once. If it stops in the middle, it is necessary to unload the press and

boring, and then start from the beginning after emptying the internal

materials.

Factors Affecting Oil Production

Depending on the batch, place of origin, variety, particle size, harvest

time, storage time and storage environment, the wild maggots are

artificially planted, imported or produced by cheese, and different

pressing processes are used, the oil output of the raw materials varies.

1. Varieties of raw materials: The same varieties, the longer the growing

period, the more oil content. Genetically modified raw materials contain

more oil.

2. Storage and recovery time: The longer the raw material is stored, the

higher the temperature, the lower the oil yield.

This manual suits for next models

3

Table of contents

Popular Power Tools manuals by other brands

Steba

Steba EM 2 Instructions for use

Harbor Freight Tools

Harbor Freight Tools 46099 Assembly and operating instructions

Festool

Festool Trion PS-300Q Original operating manual and Spare parts list

Craftsman

Craftsman CMCF940 instruction manual

SUHNER ABRASIVE

SUHNER ABRASIVE UEK 10-R Technical document

Campbell Hausfeld

Campbell Hausfeld Cl252200AV operating instructions