7

g) Use the power tool, accessories and tool bits etc., in

accordance with these instructions and in the

manner intended for the particular type of power

tool, taking into account the working conditions and

the work to be performed. Use of the power tool for

operations different from those intended could result in

a hazardous situation.

5) SERVICE

a) Have your power tool serviced by a qualified repair

person using only identical replacement parts. This

will ensure that the safety of the power tool is

maintained.

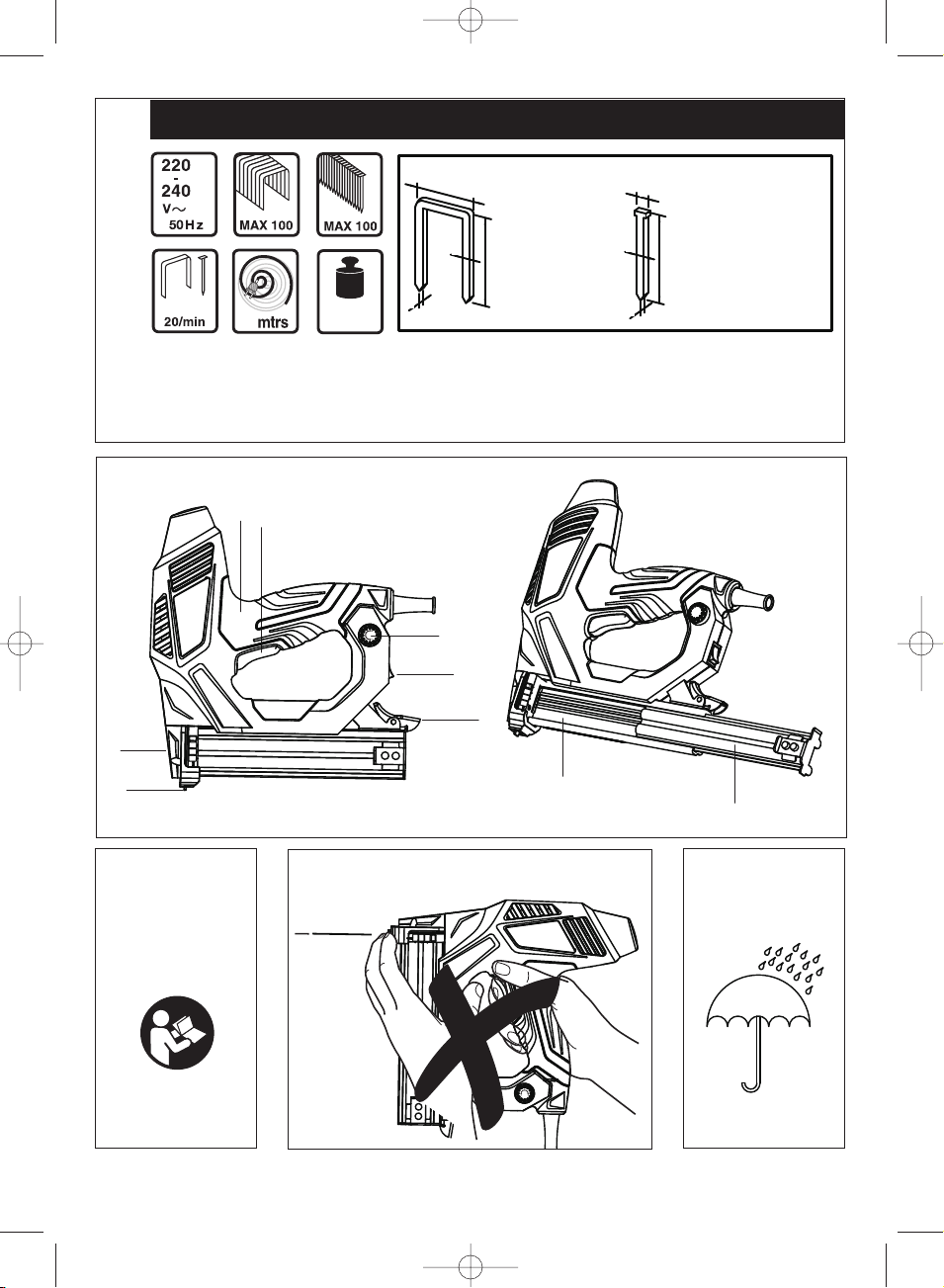

SAFETY INSTRUCTIONS FOR TACKERS

• Secure the workpiece (a workpiece clamped with

clamping devices or in a vice is held more securely than

by hand)

• Never push in the tacker head manually

4(there is

danger of injury when at the same time the trigger

is activated unintentionally)

• Never use the tool for fastening electrical wiring

(contact with electrical wires can lead to fire and electric

shock)

• Avoid damage that can be caused by screws, nails and

other elements in your workpiece; remove them before

you start working

• Always check that the supply voltage is the same as the

voltage indicated on the nameplate of the tacker

(tackers with a rating of 230V or 240V can also be

connected to a 220V supply)

• In case of electrical or mechanical malfunction,

immediately switch off the tool.

• We can assure flawless functioning of the tool only

when original accessories are used

• This tool should not be used by people under the age of

16 years

USE

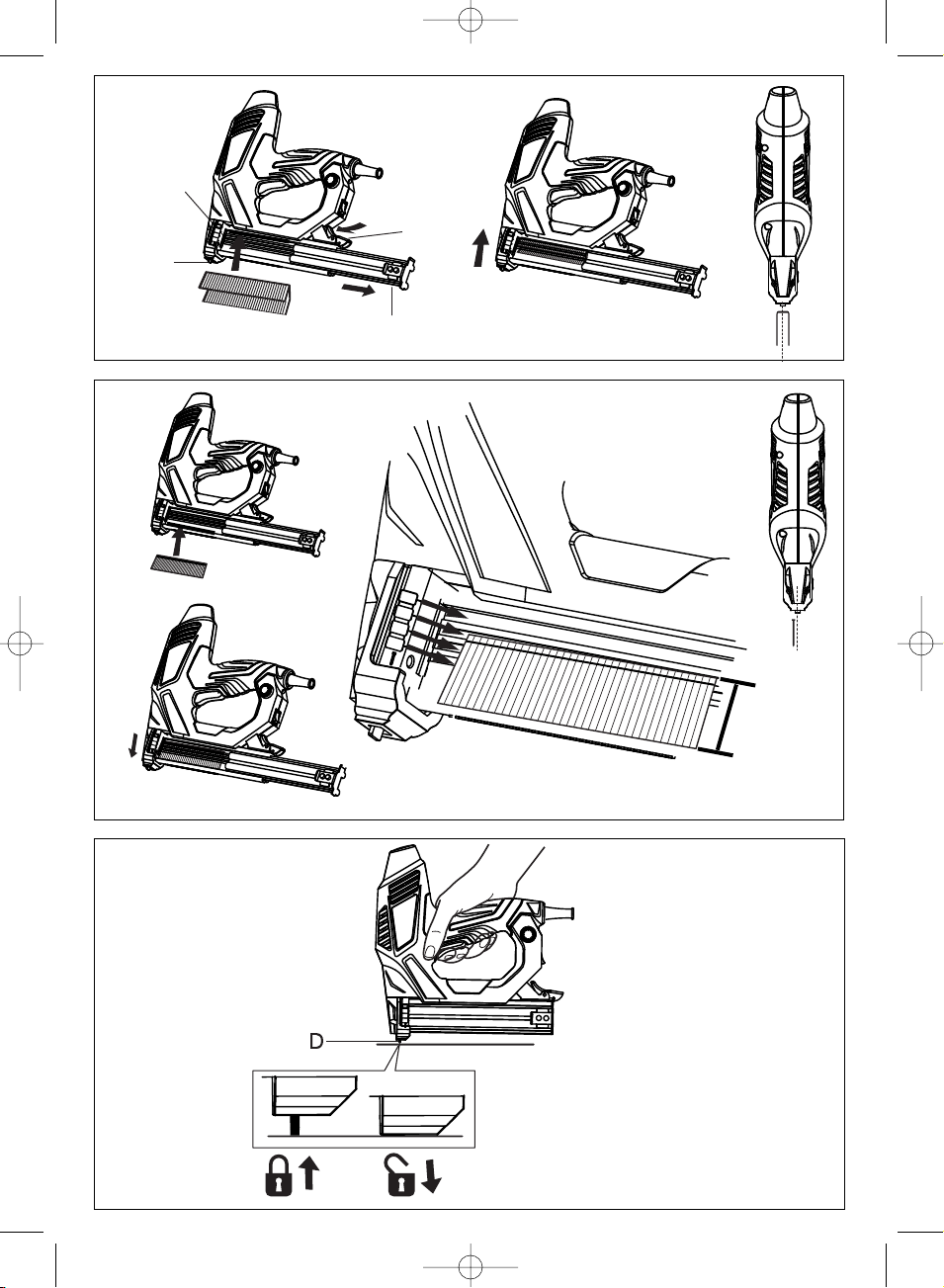

• Loading staples/nails

6

• Operating the tool 8

- firmly press tacker head D against the workpiece until

it is pushed in a few millimeters

- briefly press trigger F and then release again

- Trigger F is locked as long as you do not press tacker

head D against the workpiece,

thus preventing accidental operation

! remove all staples/nails from the magazine after

each use

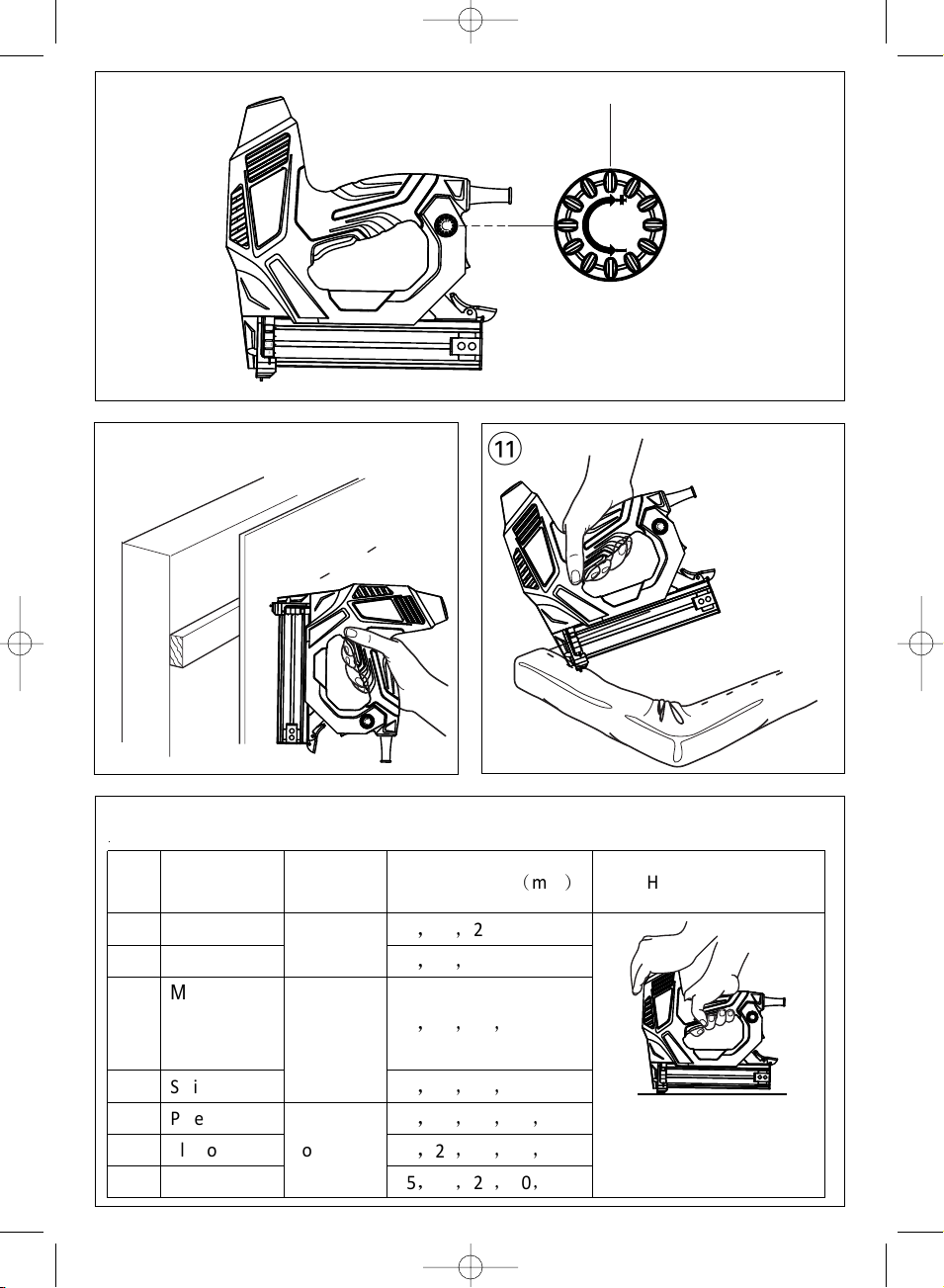

• Impact control

9

With knob G the required impact level can be adjusted

- indicator G shows the selected impact level

- “-” for thin and light materials such as foils and

fabrics

- “+” for thick and tough materials such as hard

woods and walls

- before starting a job, find the optimal impact level by

testing out on spare material

IB2100db.indd 7 06-06-2006 15:03:45

APPLICATION ADVICE

• Fastening panels

0

• Do not use the tool for fastening ceiling panelling on

profiled wood or grooves

• Fixing textiles

!

• Avoid blank shots in order to reduce the wear of the

impact strike

GUARANTEE / ENVIRONMENT

• Keep tool clean

! unplug power cord from power source before

cleaning

• This product is guaranteed in accordance with

statutory/country-specific regulations; damage due to

normal wear and tear, overload or improper handling will

be excluded from the guarantee

• In case of a complaint, send the tool or charger

undismantled together with proof of purchase to your

dealer or the nearest authorized service station

• Do not dispose of electric tools,

accessories and packaging together with household

waste material (only for EU countries)

- in observance of European Directive 2006/95/EC on

waste of electric and electronic equipment and its

implementation in accordance with national law,

electric tools that have reached the end of their life

must be collected separately and returned to an

environmentally compatible recycling facility

- symbol will remind you of this when the need for

disposing occurs

• Do not expose tool to rain. 5

- At 20 shots/min,tacker should be allowed to cool down

after 30 minutes as it is only rated for short-time duty.

• Rougly, the hardness of wood is divided into 3 levels:

NAIL INSTRUCTIONS FOR TACKERS

• Nails of different length are applicable for different wood hardness

• The tool has a recoil when firing, so two hands operation is

- High

- Medium

- Low

suggested, to have a better control of the operation

UNBLOCKING JAMMED FASTENERS

• In the unlikely event that nails become jammed, follow these

instructions to remove them

- Remove the nose tip I

- Remove the plate retaining bolts C1

- Remove the safety mechanism retaining plate C2

- Remove the firing pin retaining plate C3

! Note the location as well as the order in which parts are

removed from the tacker, this will make it easier to rebuild it

1313

14

14

14

! unplug power cord from power source before removing

15

- tilt the tool or lay the tool flat, so the staples or nails will

- press lever A while pulling slider B backwards

- place the nail strip into magazine C (maximal capacity

100 nails)

- push slider B against tacker head D until it snaplocks

7

not drop out while loading

! Attention

Make sure that

- the nail strip is loaded with the tapered end aligning

with the bottom line of the magazine C, so the brad

nail head rest right into the grooves which corresponds

with the symbol of nail length on tacker head D

- the staple strip is loaded with the crown aligning

with the top line of the magazine C 6