Table of contents

1 Technical highlights............................................................................................................................................................. 6

1.1 Electrical characteristics............................................................................................................................................... 7

1.1.1 Mains filtering................................................................................................................................................... 7

1.1.2 Transformers..................................................................................................................................................... 7

1.1.3 Rectifying and filtering secondary windings......................................................................................................... 7

1.1.4 Discrete regulation............................................................................................................................................. 7

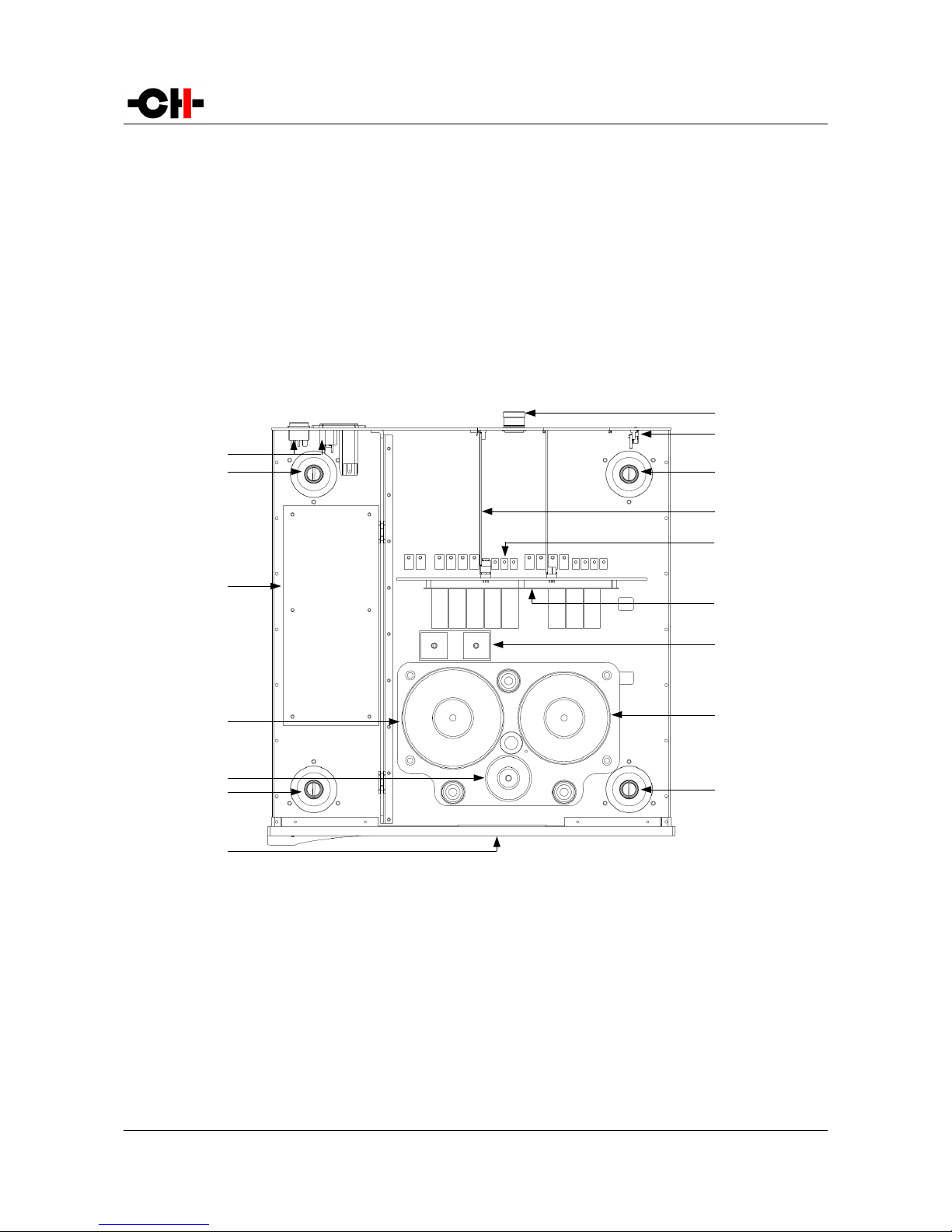

1.2 Mechanical construction.............................................................................................................................................. 8

2 Before use.......................................................................................................................................................................... 9

2.1 Pac age content......................................................................................................................................................... 9

2.2 Safety notice.............................................................................................................................................................. 9

2.3 User manual............................................................................................................................................................ 10

2.4 Mains supply............................................................................................................................................................ 10

2.5 Transport and pac aging........................................................................................................................................... 10

2.6 Cleaning.................................................................................................................................................................. 11

2.7 Maintenance and service........................................................................................................................................... 11

3 Installation....................................................................................................................................................................... 12

3.1 Unpac ing your unit................................................................................................................................................. 12

3.2 Positioning your unit................................................................................................................................................ 12

3.3 Connections.............................................................................................................................................................. 13

3.3.1 CONTROL board............................................................................................................................................... 14

3.3.1.1 USB port................................................................................................................................................. 15

3.3.1.2 Push-buttons........................................................................................................................................... 15

3.3.2 POWER SOURCE board..................................................................................................................................... 15

3.3.2.1 Power connector..................................................................................................................................... 15

3.3.3 Power cord receptacle and voltage selection...................................................................................................... 16

4 Operation......................................................................................................................................................................... 17

4.1 Front panel.............................................................................................................................................................. 17

4.2 Configuration........................................................................................................................................................... 18

5 Firmware update.............................................................................................................................................................. 19

5.1 Introduction............................................................................................................................................................. 19

5.2 Firmware update procedure...................................................................................................................................... 19

5.2.1 Preparing the firmware image.......................................................................................................................... 19

5.2.2 Updating the firmware..................................................................................................................................... 19

6 Troubleshooting................................................................................................................................................................ 21

7 Specifications.................................................................................................................................................................... 22

Rev 2.1 X1 User Manual 5