1.0 Introduction

3

TABLE OF CONTENTS

1.0 Introduction ...................................................................................................................................... 2

2.0 Safety............................................................................................................................................... 4

2.1 Precautions.................................................................................................................................. 4

2.2 Power Lockout Procedure ........................................................................................................... 4

2.3 Warning Label Definitions............................................................................................................ 5

3.0 Packing List...................................................................................................................................... 6

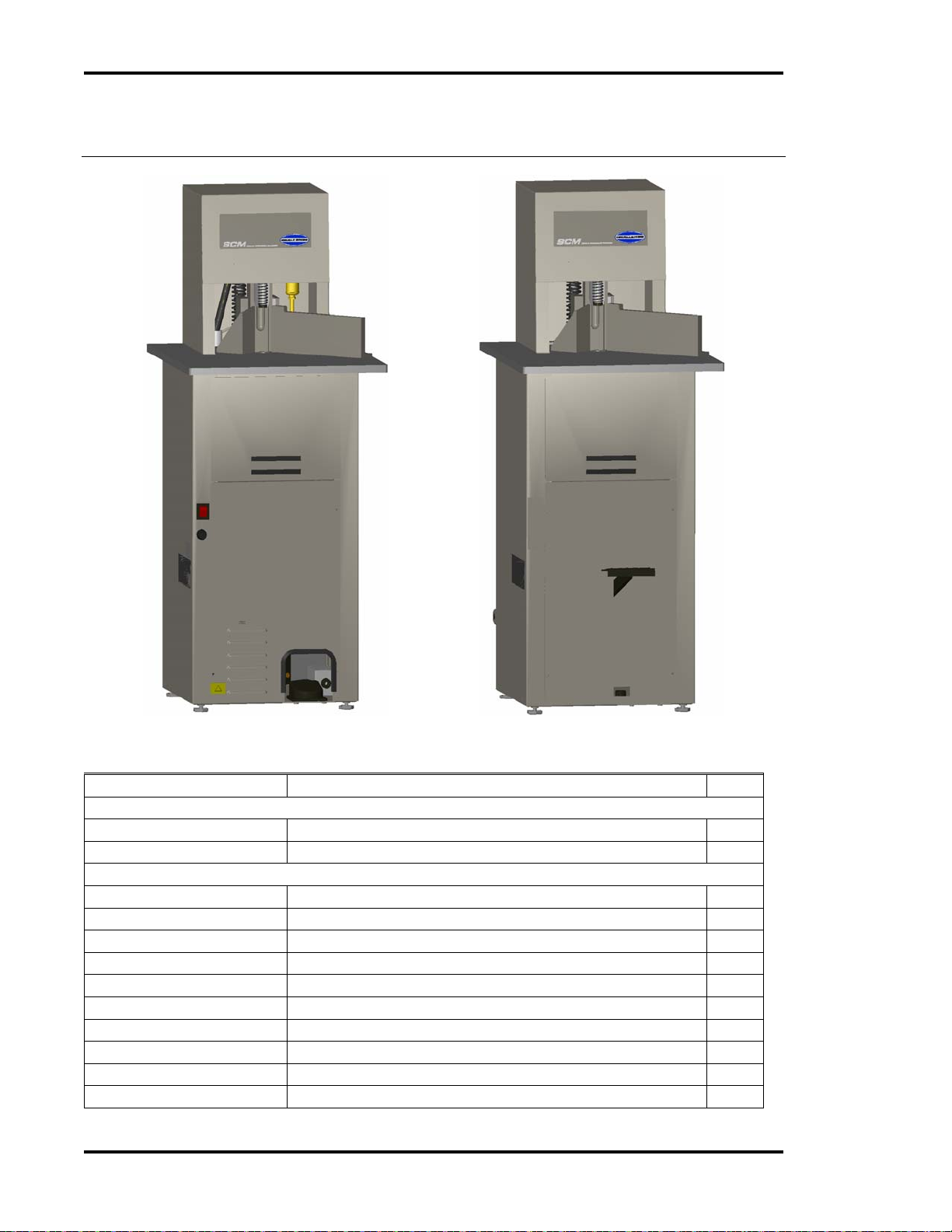

4.0 Specifications................................................................................................................................... 8

5.0 Accessories...................................................................................................................................... 9

6.0 Installation Guide ........................................................................................................................... 10

6.1 Inspecting Shipment.................................................................................................................. 10

6.2 Unpacking.................................................................................................................................. 10

6.3 Leveling ..................................................................................................................................... 10

6.4 Cleaning..................................................................................................................................... 10

6.5 Power Hook-up (SCM only)....................................................................................................... 10

6.6 Knife and Die Installation........................................................................................................... 10

7.0 User’s Guide .................................................................................................................................. 11

7.1 SCM/MSCM Diagrams .............................................................................................................. 11

7.2 SCM Operation.......................................................................................................................... 13

7.3 MSCM Operation (Manual Machine)......................................................................................... 13

7.4 Side and Back Gauge Adjustment............................................................................................. 13

7.5 Knife and Die Change................................................................................................................ 14

7.6 Straight Diagonal Cutting........................................................................................................... 16

7.7 Lubrication................................................................................................................................. 16

7.8 Operating Tips........................................................................................................................... 17

8.0 Appendix A - Maintenance Guide.................................................................................................. 18

8.1 Mechanical System.................................................................................................................... 19

8.1.1 Knife Return Springs.......................................................................................................... 19

8.1.2 Dovetail Gib........................................................................................................................ 19

8.1.3 Hydraulic System (SCM only) ............................................................................................ 20

8.1.4 Hydraulic Fluid Check ........................................................................................................ 20

8.1.5 Replacing Hydraulic Fluid................................................................................................... 21

8.1.6 Hydraulic Fluid Compatibility List ....................................................................................... 22

8.2 Electrical System (SCM only).................................................................................................... 22

8.2.1 Fuse Check and Replacement........................................................................................... 22

9.0 Appendix B–Parts List.................................................................................................................... 23

9.1 Mechanical................................................................................................................................. 23

9.1.1 A-8300-2 Main Assembly- Knife Head............................................................................. 23

9.1.2 A-8300-2 Main Assembly- Knife Head (Rear).................................................................. 25

9.1.3 A-8300-2 Main Assembly- Underside .............................................................................. 27

9.1.4 A-8300-2 Main Assembly- Hood...................................................................................... 29

9.1.5 A-8300-2 Main Assembly- Base....................................................................................... 31

9.1.6 A-8300-2 Main Assembly- MSCM.................................................................................... 33

9.1.7 83001 Hydraulic Power Unit Assembly- SCM, Rev. B..................................................... 35

9.2 Electrical .................................................................................................................................... 36

9.2.1 E-3042 Basic Machine Schematic ................................................................................... 36

9.2.2 E-3042 Interconnection Diagram ..................................................................................... 37

10.0 Appendix C- Troubleshooting ...................................................................................................... 38